| CATEGORII DOCUMENTE |

| Bulgara | Ceha slovaca | Croata | Engleza | Estona | Finlandeza | Franceza |

| Germana | Italiana | Letona | Lituaniana | Maghiara | Olandeza | Poloneza |

| Sarba | Slovena | Spaniola | Suedeza | Turca | Ucraineana |

AN INTRODUCTION TO

SEA TRANSPORT OF

CHEMICALS IN BULK

BRIEF HISTORY OF THE TRADE

Organic and inorganic

chemicals were first synthesised on an industrial scale using coal, limestone,

cellulose or molasses as raw materials in the early 1900s. The first

petrochemical plants were developed in the

Bulk shipment of liquid

chemicals began in the mid‑1940s using standard oil product tankers. At

about the same time, some traditional cargo ships were equipped with deep tanks

suitable for carrying vegetable oils as part of their liner cargo service. The

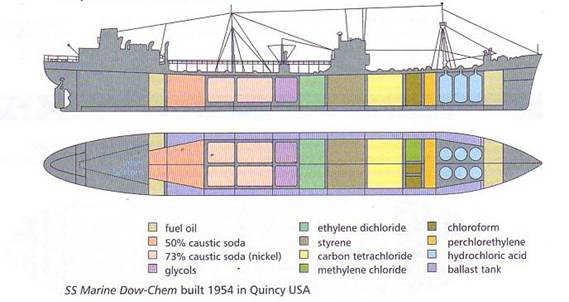

first tanker to be specially designed to carry chemicals in bulk was the Marine Dow‑Chem, a twin‑screw

steam turbine ship built in 1954 in the

SS Marine Dow‑Chem built 1954 in

Since that time, the range of chemicals shipped in bulk has increased enormously and a special class of ships has been developed to meet this need ‑ the chemical tanker. Most early chemical tankers were slightly modified product tankers, in which the main variation was coating of the cargo tanks. Although many of the products shipped could be carried quite safely in uncoated mild steel tanks, the need to maintain product quality, to minimise the potential for discoloration, and to facilitate tank cleaning between cargoes led to tank surfaces being coated with an impervious material.

As the shipment of bulk chemicals developed, different countries involved with the trade developed regulations to minimise the risk to the ship, its crew and the environment, and applied them to their own ships and ships trading to their ports. These regulations were not an the same, and it was extremely difficult for a ship and its crew to comply with them all. To establish an international standard for the safe design, construction and equipment of chemical tankers, IMO developed the Bulk Chemical Codes. It was a major step forward. A ship that complies with the IMO Codes is issued with a Certificate of Fitness that is recognised internationally, and enables the ship to trade worldwide carrying the cargoes for which it is approved.

The cargoes now carried in these ships range from petrochemicals used as feedstock for plastics or synthetic rubbers and fibres, industrial acids and alkalis, alcohols and solvents, highly refined lubricating oils and lubricating oil additives, to detergents, animal and vegetable oils, and edible products such as fruit juices or wine. Furthermore, certain refined petroleum products that were previously considered to be oils are now classified as chemicals under IMO marine pollution or toxicity regulations, and must only be carried by chemical tankers.

CHEMICAL TANKER CARGOES

Chemical tanker cargoes may be divided into four main groups:

Petrochemicals. This is the collective name for organic chemicals derived from crude oil, natural gas and coal. Organic chemicals are those produced from living or once‑living organisms, petroleum and natural gas (marine animals and plants) and coal (plants). It is now possible to synthesise organic chemicals from inorganic chemicals to the extent that 'organic chemicals' really means those compounds based upon the element carbon. But the term does not include the simplest carbon compounds such as carbon dioxide, carbon monoxide and the carbonates.

Alcohols and carbohydrates. Alcohols may be derived from hydrocarbons or produced by fermentation.

Vegetable and animal oils and fats. Derived from the seeds of plants and from the fat of animals and fish.

Acids and inorganic chemicals. Inorganic chemicals are those that are not produced from living or once‑living organisms. However, a number of inorganic chemicals such as sulphur and ammonia can be manufactured using petroleum as the raw material. Acids may be organic or inorganic.

TYPES OF CHEMICAL TANKERS

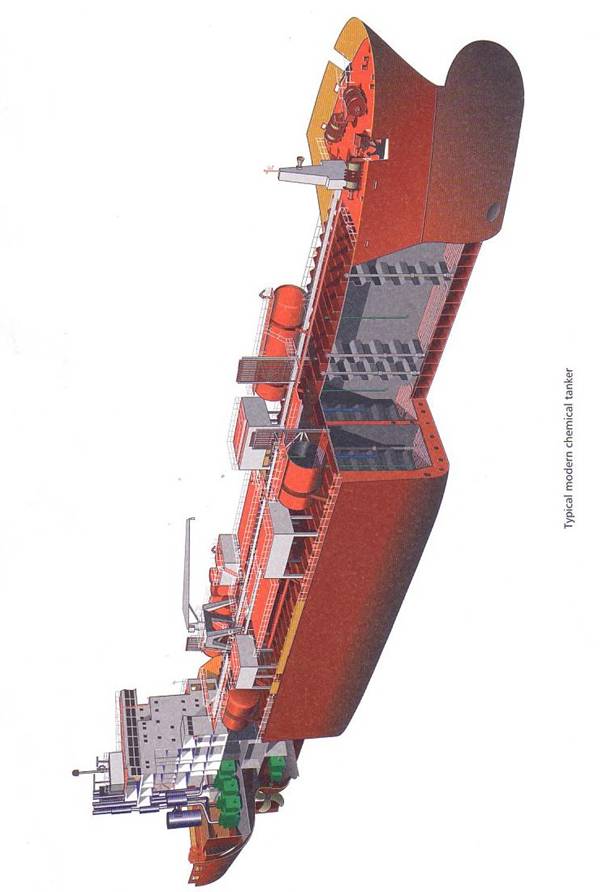

A modem chemical tanker is primarily designed to carry some of the several hundred hazardous products now covered by the IMO Bulk Chemical Codes. The following general types of chemical carriers have developed since the trade began:

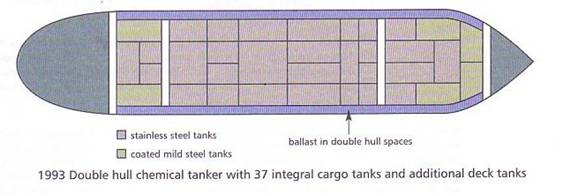

1993 Double hull chemical tanker with 37 integral cargo tanks and additional deck tanks

Sophisticated parcel chemical tankers: typically up to 40,000 tonnes deadweight with multiple small cargo tanks ‑ up to 54 ‑ each with an individual pump and a dedicated pipeline, to carry small parcels of high grade chemicals. These ships have a significant proportion of the cargo tanks made with stainless steel, allowing maximum flexibility to carry cargoes that need their quality safeguarded.

Product / chemical tankers: of similar size to parcel tankers but with fewer cargo tanks, mostly of coated steel rather than stainless, and less sophisticated pump and line arrangements. Such ships carry the less difficult chemicals, and also trade extensively with clean oil products.

Specialised chemical carriers: small to medium sized ships, often on dedicated trades and usually carrying a single cargo such as an acid, molten sulphur, molten phosphorus, methanol, fruit juice, palm oil and wine. Cargo tanks are coated or stainless steel according to the trade.

CHAPTER I

HAZARDS AND PROPERTIES OF CHEMICALS

Introduction

Flammability

Health Hazards

.1 Toxicity

.2 Asphyxia

.3 Anaesthesia

.4 Additional health hazards

Reactivity

.1 Self‑reaction

.2 Reaction with water

.3 Reaction with air

.4 Reaction with other cargoes

.5 Reaction with other materials

Corrosiveness

Putrefaction

Physical Properties

.1 Specific gravity

.2 Vapour pressure and boiling point

.3 Freezing point

.4 Cubic expansion

.5 Vapour density

.6 Solubility

.7 Electrostatic charging

.8 Viscosity

HAZARDS AND PROPERTIES OF CHEMICALS

This chapter gives an introduction to the range of hazards normally associated with the properties of chemicals that are carried as cargoes, and the precautions necessary to minimise or avoid those hazards.

1.1 INTRODUCTION

Chemical tankers are required to transport a wide range of different cargoes, and many tankers are designed to carry a large number of segregated products simultaneously. The operation of chemical tankers differs from any other bulk liquid transportation operations, in that on a single voyage a large number of cargoes with different properties, characteristics and inherent hazards may be carried. Moreover, in port several products may be handled simultaneously at one berth, typically including different operations such as discharge and loading as well as tank cleaning. Even the less sophisticated chemical tankers are more complex to operate than oil tankers.

Transportation of bulk chemicals by sea not only requires specialist ships and equipment, but also specialist crew training, both theoretical and practical, in order for those involved to understand the characteristics of the various chemicals and be aware of the potential hazards involved in handling them. A particularly important aspect of this requirement is the provision of a data sheet, or cargo information form, giving details specific to a substance, to be held on board whenever that substance is carried by the ship (see Section 2.2).

The following notes are only intended to indicate the most common characteristics and hazards of chemicals transported by sea in bulk. More detailed information on the main hazards and properties will be found in relevant chapters and appendices, where guidance is also given on the precautions to be taken.

1.2 FLAMMABILITY

Vapour given off by a flammable liquid will burn when ignited provided it is mixed with certain proportions of air, or more accurately with the oxygen in air. But if there is too little or too much vapour compared to the air, so that the vapour‑and‑air mixture is either too lean or too rich, it will not burn. The limiting proportions, expressed as a percentage by volume of flammable vapour in air, are known as the lower flammable limit (LFL) and the upper flammable limit (UFL), and the zone, in between is the flammable range (see Definitions for further details). Combustion of a vapour‑and‑air mixture results in a very considerable expansion of gases which, if constricted in an enclosed space, can raise pressure rapidly to the point of explosive rupture.

In addition, a flammable liquid must itself be at or above a temperature high enough for it to give off sufficient vapour for ignition to occur. This temperature is known as the flash point. Some cargoes evolve flammable vapour at ambient temperatures, others only at higher temperatures or when heated. Safe handling procedures depend upon the flammability characteristics of each product. Non‑combustible cargoes are those which do not evolve flammable vapours.

As mentioned, the fire risk presented by a flammable cargo depends upon the oxygen content of the atmosphere above it. By filling the ullage space in a cargo tank with an inert gas such as nitrogen or the output of an oil fired inert gas generator, the oxygen content can be reduced to a level at which the atmosphere will no longer support combustion of flammable vapour.

This is known as inerting a tank. But it is important to remember that an inerted atmosphere may become flammable again if air is admitted, for instance during routine measuring or on venting the mixture to atmosphere or during gas freeing with air (see Chapter 6 for guidance on cargo tank atmospheres).

An inert atmosphere must not be considered as being without hazard, however, as without enough oxygen it will not support life either. Any person entering a tank which has been inerted must always follow strict procedures for entry into enclosed spaces (see Chapter 3).

1.3 HEALTH HAZARDS

1.3.1 Toxicity

Toxic means the same as poisonous. Toxicity is the ability of a substance, when inhaled, ingested, or absorbed by the skin, to cause damage to living tissue, impairment of the central nervous system, severe illness or, in extreme cases, death.

The amounts of exposure required to produce these results vary widely with the nature of the substance and the duration of exposure to it.

Acute poisoning occurs when a large dose is received by exposure to high concentrations of a short duration, i.e. a single brief exposure. Chronic poisoning occurs through exposure to low concentrations over a long period of time, i.e. repeated or prolonged exposures. Toxicity is objectively evaluated on the basis of test dosages under controlled conditions, and expressed as threshold limit values (TLVs). A full explanation is given in Appendix A.

Prevention of exposure is achieved through a combination of cargo containment, which prevents toxic fumes or liquid from contaminating the workplace, and the use of personal protective equipment (PPE). The latter is described in Chapter 9.

1.3.2 Asphyxia

Asphyxia is unconsciousness caused by lack of oxygen, and means suffocation. Any vapour may cause asphyxiation, whether toxic or not, simply by excluding oxygen in air. Danger areas include cargo tanks, void spaces and cargo pumprooms. But the atmosphere of a compartment may also be oxygen‑deficient through natural causes, such as decomposition or putrefaction of organic cargo (see Appendix Q, or rusting of steel in void spaces such as cofferdams, forepeak and afterpeak tanks. Precautions to be observed before entering these spaces are described in Chapter 3.

1.3.3 Anaesthesia

Certain vapours cause loss of consciousness due to their effect on the nervous system. In addition, anaesthetic vapours may or may not be toxic.

1.3.4 Additional health hazards

Additional health hazards may be presented by non‑cargo materials used on board during cargo handling. One hazard is that of frostbite from liquid nitrogen stored on board for use as atmosphere control in cargo tanks. Full advice on dealing with frostbite is contained in the MFAG (see Definitions). Another hazard is that of burns from accidental contact with equipment used while handling heated cargoes.

1.4 REACTIVITY

A chemical may react in a number of ways; with itself, with water, with air, with other chemicals or with other materials.

1.4.1 Self‑reaction

The most common form of self‑reaction is polymerisation. Polymerisation generally results in the conversion of gases or liquids into viscous liquids or solids. It may be a slow, natural process which only degrades the product without posing any safety hazards to the ship or the crew, or it may be a rapid, exothermic reaction evolving large amounts of heat and gases. Heat produced by the process can accelerate it. Such a reaction is called a run‑off polymerisation that poses a serious danger to both the ship and its personnel. Products that are susceptible to polymerisation are normally transported with added inhibitors to prevent the onset of the reaction. See Appendix C for details.

An inhibited cargo certificate should be provided to the ship before a cargo is carried. An example is shown in Appendix N. The action to be taken in case of a polymerisation situation occurring while the cargo is on board should be covered by the ship's emergency contingency plan.

1.4.2 Reaction with water

Certain cargoes react with water in a way that could pose a danger to both the ship and its personnel. Toxic gases may be evolved. The most noticeable examples are the isocyanates; such cargoes are carried under dry and inert condition. Other cargoes react with water in a slow way that poses no safety hazard, but the reaction may produce small amounts of chemicals that can damage equipment or tank materials, or can cause oxygen depletion.

1.4.3 Reaction with air

Certain chemical cargoes, mostly ethers and aldehydes, may react with oxygen in air or in the chemical to form unstable oxygen compounds (peroxides) which, if allowed to build up, could cause an explosion. Such cargoes can be either inhibited by an anti‑oxidant or carried under inert conditions.

1.4.4 Reaction with other cargoes

Some cargoes react dangerously with one another. Such cargoes should be stowed away from each other (not in adjacent tanks) and prevented from mixing by using separate loading, discharging and venting systems. When planning the cargo stowage, the master must use a recognised compatibility guide to ensure that cargoes stowed adjacent to each other are compatible.

1.4.5 Reaction with other materials

The materials used in construction of the cargo systems must be compatible with the cargo to be carried, and care must be taken to ensure that no incompatible materials are used or introduced during maintenance (e.g. by the material used for replacing gaskets). Some materials may trigger a self‑reaction within the product. In other cases, reaction with certain alloys will be non‑hazardous to ship or crew, but can impair the commercial quality of the cargo or render it unusable.

1.5 CORROSIVENESS

Acids, anhydrides and alkalis are among the most commonly carried corrosive substances. They can rapidly destroy human tissue and cause irreparable damage. They can also corrode normal ship construction materials, and create a safety hazard for a ship. Acids in particular react with most metals, evolving hydrogen gas which is highly flammable. The IMO Codes address this, and care should be taken to ensure that unsuitable materials are not included in the cargo system. See Appendix B.

Personnel likely to be exposed to these products should wear suitable personal protective equipment (see Chapter 9).

1.6 PUTREFACTION

Most animal and vegetable oils undergo decomposition over time, a natural process known as putrefaction (going off), that generates obnoxious and toxic vapours and depletes the oxygen in the tank. Tanks that have contained such products must be carefully ventilated and the atmosphere tested prior to tank entry (see Chapter 3).

It must not be assumed that all vapours produced by cargoes liable to putrefaction will in fact be due to putrefaction; some may not be obvious, either through smell or appearance of the cargo. Carbon monoxide (CO), for instance, is colourless and odourless and can be produced when a vegetable or animal oil is overheated.

1.7 PHYSICAL PROPERTIES

1.7.1 Specific gravity

Cargo tanks on a chemical tanker are normally designed to carry cargoes of a higher specific gravity than an oil tanker. Sometimes the design strength even differs between tanks on the same ship.

The information regarding tank strength may be found on the classification society's certification of the ship, and the master must be familiar with any restrictions that may be imposed on loading heavy cargoes. Especially important is the risk of slack loading a tank because this can lead to sloshing forces that may cause damage to the tank structure or its equipment. Likewise, the tank's design capacity must be strictly observed: exceeding it is dangerous. Note that the cargo's specific gravity and its vapour pressure must be considered together.

1.7.2 Vapour pressure and boiling point

At any given temperature every liquid exerts a pressure called the vapour pressure. The liquid will boil when its vapour pressure equals the external atmospheric pressure.

In a closed cargo tank a liquid will boil when the vapour pressure is equal to the external vapour pressure plus the pressure setting of the pressure/vacuum (P/V) valve. The tanks and vent systems are designed to withstand this pressure, plus the hydrostatic pressure of the cargo. Cargoes that exceed the normal atmospheric pressure at 37.8'C (100'F) should not be loaded into a tank that is not specially designed for that duty. Where a P/V valve set point can be varied, the correct setting should be confirmed. Vent line systems must be checked for correct operation at regular intervals, as structural damage can easily result from malfunction or blockage due to freezing of cargo vapour, polymer build‑up, atmospheric dust or icing in adverse weather conditions. Flame screens are also susceptible to blockage, which can cause similar problems.

The higher the vapour pressure the more vapours will be released, a fact that may require use of personal protective equipment.

1.7.3 Freezing point

Most liquids have a defined freezing or solidification point, sometimes described as the melting point. Some products, such as lubricating oil additives, vegetable and animal oils, polyols etc. do not have a defined point, but a freezing or melting range. For such cargoes, viscosity is used as a measurement of the product's liquidity or handling characteristics, and the term pour point is used instead. Cargoes with a freezing point higher than the ambient temperature of the ship's trading areawill need to be heated in order to remain liquid.

The structure and equipment of a ship normally impose a limitation on the carriage of heated cargoes. Exceeding this limitation could damage the tank coating or its structure. Excessive heat will also create thermal stresses, and the risk of cracking will increase. (Note that moderate heat increases steel strength; it is expansion forces that are the immediate limiting factor.) Caution should be exercised when carrying high heat products because cargo in non- insulated pipes and vents may freeze the systems. Heating arrangements must be operated in accordance with design safety precautions; for example, pressures inside heating coils in tanks must be kept higher than the cargo pressure, and any interceptor tanks between heating return lines and the engine room must be checked regularly to detect any contamination. For certain cargoes, heating coils must be blanked off in accordance with IBC Code requirements.

Uninsulated cargo pipes used for high heat products pose a further safety hazard, as they may cause severe burns if touched.

1.7.4 Cubic expansion

Liquids will expand as temperature rises, or contract when temperature falls. Sufficient space must be allowed in the tank to accommodate any cubic expansion expected during the voyage. A useful formula is:

Filling ratio (% full) = 100 (1 ‑ RT) ‑ S

where R = coefficient of expansion per 'C (from cargo data sheet)

T = expected maximum temperature rise in 'C (during voyage)

S = safety margin, usually 2% of tank capacity.

Vent line systems must be checked at regular intervals. Their design capacity is based on vapour flow only; structural damage may result if vent systems become full of cargo liquid due to thermal expansion.

1.7.5 Vapour density

Vapour density is expressed relative to the density of air, as heavier or lighter. Most chemical cargo vapours are heavier than air. Caution must therefore be exercised during cargo operations, as vapour concentrations are likely to occur at deck level or in lower parts of cargo pump-rooms.

1.7.6 Solubility

Solubility is expressed in different ways: either as a simple yes or no, as slight, or as a percentage, but always in relation to water. Solubility is temperature dependant. A cargo with low solubility will form a layer above or below a water layer depending on its specific gravity. Most non‑soluble chemicals are lighter than water and will float on top but some others, such as chlorinated solvents, are heavier and will sink to the bottom. Chemicals that are heavier than water can cause a safety risk in pump-rooms when the overlying water is disturbed, and in drip trays. Even in cargo tanks they may be trapped under water in pump wells, and pose a danger even after the tank atmosphere is tested and found safe for entry.

1.7.7 Electrostatic charging

Certain cargoes are known as static accumulators, and become electrostatically charged when handled. They can accumulate enough charge to release a spark that could ignite a flammable tank atmosphere. The precautions necessary to prevent ignition from electrostatic charging are contained in Chapter 5, and a description of the phenomenon itself is given in Appendix D.

1.7.8 Viscosity

The viscosity of a cargo determines how easy it is to pump, and the amount of residue that will be left after unloading. Viscosity is related to temperature and, in general, a substance will become less viscous at higher temperatures, but note that certain cargoes (such as luboil additives) show increased viscosity when heated. IMO standards define high and low viscosity substances, and require cargo tanks that have contained substances with a high viscosity to be pre‑washed and the washings discharged to shore reception facilities.

CHAPTER 2

GENERAL PRECAUTIONS

2.1 Introduction

2.2 Cargo Information

2.3 Moorings

2.4 Emergency Towing‑off Wires (Fire Wires)

2.5 Access to Ship

.1 Means of access (gangways or accommodation ladders)

.2 Lighting

.3 Unauthorised persons

.4 Persons smoking or intoxicated

2.6 Notices

.1 Permanent

.2 Temporary

2.7 Effects of Other Ships and Berths

.1 Tugs and other craft alongside

.2 Other tankers at adjacent berths

.3 Chemical tanker operations at general cargo berths

2.8 Weather Precautions

.1 Wind conditions

.2 Electrical storms

.3 Cold weather

2.9 Openings in Deckhouses and Superstructures

2.10 Engine and Boiler Room

.1 Combustion equipment

.2 Blowing boiler tubes

.3 Cargo vapour

2.11 Ship/Shore Insulating and Earthing

.1 Insulating

.2 Ship/shore bonding cables

2.12 Hot Work

.1 General

.2 Assessment of hot work

.3 Preparations for hot work

.4 Checks by officer responsible for safety during hot work

.5 Action on completion of hot work

2.13 Use of Tools for Ship's Maintenance

.1 Power tools

.2 Hand tools

Pumprooms and Enclosed Spaces

.1 Cargo pumprooms

.2 Enclosed spaces

Ship's Readiness to Move

Navigation

Pollution Prevention

Fire Fighting and Fire Protection Equipment

Helicopters

Tank Cleaning and Gas Freeing

.1 Awareness of additional hazards

.2 Use of tank cleaning agents

Communication Equipment

.1 Ship's radio transmission equipment

.2 Personal items

GENERAL

PRECAUTIONS

This chapter deals with general precautions which should be observed on a chemical tanker, irrespective of the cargoes being carried. A chemical tanker has many potential dangers, and the need for constant vigilance is recognised in the extensive training of crew members and the safety procedures that have been established. Additional precautions for specific cargoes are dealt with in other chapters.

2.1 INTRODUCTION

Care and attention should be given to safety precautions at all times, both in port and at sea. The concept of safety first should be incorporated into the ship's operational and cargo handling manuals. Prior knowledge of a possible problem usually allows it to be avoided through precautionary planning or by the development of safe working practices. Ports and terminals may specify the need for additional and different precautions. It is the master's responsibility to see that local regulations are understood and observed.

2.2 CARGO INFORMATION

The IMO Codes require that certain information must be available on board the ship for each particular cargo, and prior to loading. The information should include:

A full description of the physical and chemical properties, including reactivity, necessary for the safe contaimnent‑of the cargo.

Compatibility with other materials.

Action to be taken in the event of spills or leaks.

Countermeasures against accidental personal contact.

Fire fighting procedures and fire extinguishing media.

Procedures for cargo transfer, tank cleaning, gas freeing and ballasting.

Whether the chemical is stabilised.

The correct technical name of the cargo should be available, and only cargoes for which the ship is approved should be loaded. For those cargoes required to be stabilised or inhibited, the cargo should be refused if an inhibited cargo certificate (see Appendix N) is not supplied.

It is the shipper's responsibility to provide the necessary information, which may be given in the form of a cargo information form or data sheet for each cargo. Loading should not commence before the master is satisfied that the necessary information for safe handling of the cargo is available to the personnel involved.

2.3 MOORINGS

Chemical terminals are often located in tidal areas or rivers, with other ships passing at close distance, thus making proper mooring a significant safety issue. The consequences of a chemical tanker ranging along a jetty or breaking away from a berth could be disastrous, especially during a cargo transfer involving multiple different chemicals. Correct and sufficient mooring is therefore of the utmost importance.

Mooring requirements and arrangements are usually determined by the location and the layout of the terminal, supplemented by advice from the pilot.

Moorings should be regularly checked and tended to ensure that they remain effective. The master should ensure that, during cargo operations, sufficient personnel are available for mooring adjustments.

2.4 EMERGENCY TOWING ‑OFF WIRES (FIRE WIRES)

The ship should provide towing‑off wires, ready for immediate use without adjustment, in case the ship needs to be moved in the event of fire or other emergency. In most ports, emergency towing‑off wires are mandatory when at a berth.

Wires should be positioned fore and aft on the offshore side of the ship. They should be in good condition, of adequate strength, and properly secured to the bitts such that full towing loads can be applied. The eyes should be maintained at or about the waterline in a position that tugs can easily reach. Sufficient slack to allow the tugs to tow effectively should be retained between the bitts and the fairlead, but prevented from running out by a rope yarn or other easily broken means.

There are various methods currently in use for rigging emergency towing‑off wires, and the arrangement may vary from port to port. A terminal which requires a particular method to be used should advise the ship accordingly.

2.5 ACCESS TO SHIP

2.5.1 Means of access (gangways or accommodation ladders)

Personnel should only use the designated means of access between ship and shore, or between ships.

When a ship is berthed, at anchor or alongside another ship, the means of access should be close to the living accommodation, placed conveniently for supervision, and if possible away from the cargo manifold area. Gangways or other means of access should be properly secured and provided with an effective safety net. Suitable lifesaving equipment such as a lifebuoy should be available near the access point. ‑

2.5.2 Lighting

During darkness the means of access and the surrounding areas should be adequately illuminated.

2.5.3 Unauthorised persons

Persons who have no legitimate business on board, or who do not possess the master's permission to be there, should be refused access. A crew list should be provided to the terminal security personnel who, in agreement with the master, should restrict access to the jetty or berth to people who can demonstrate legitimate business with the ship.

2.5.4 Persons smoking or intoxicated

Personnel on watch on a chemical carrier must ensure that no one who is smoking approaches or boards the ship. Smoking on board must only take place in designated smoking areas. The company policy on drugs and alcohol must be strictly enforced.

2.6 NOTICES

2.6.1 Permanent

Permanent notices should be displayed in conspicuous places on board, indicating where smoking and use of naked lights are prohibited, and where ventilation is necessary prior to entry.

2.6.2 Temporary

On arrival at a terminal, a chemical tanker should display temporary notices at points of access to the ship, in English and other appropriate languages, to indicate the following:

WARNING

NO NAKED LIGHTS

NO SMOKING

NO UNAUTHORISED PERSONS

In addition, when the chemicals being handled present a health hazard, further notices in appropriate languages should be prominently displayed stating:

WARNING

HAZARDOUS CHEMICALS

Local national or port regulations may require additional notices, and such requirements should be observed.

2.7 EFFECTS OF OTHER SHIPS AND BERTHS

2.7.1 Tugs and other craft alongside

The number of craft which come alongside and the duration of their stay should be kept to a minimum. Subject also to port authority regulations, only authorised craft having the permission of the responsible officer, and where applicable the terminal representative, should be permitted to come alongside or remain alongside a chemical tanker while it is engaged in cargo operations. If an unauthorised craft comes alongside or operates in an area which may create a danger, it should be reported to the port authority and, if necessary, cargo transfer operations should cease.

The responsible officer should instruct personnel manning any craft alongside that the same safety regulations that apply on the chemical tanker must be observed on the craft. In the event of a breach of the regulations operations should be stopped, and should not be restarted until the situation has been made safe.

2.7.2 Other tankers at adjacent berths

Even when no cargo operations are being undertaken while at a terminal, dangerous concentrations of cargo vapour may be encountered if cargo or ballast handling, inerting, tank cleaning or gas freeing operations are being conducted by another tanker at an adjacent berth. In such circumstances appropriate precautions should be taken.

2.7.3 Chemical tanker operations at general cargo berths

Where chemical tanker operations need to be conducted at general cargo berths it is unlikely that personnel on such berths will be familiar with the full range of safety requirements relating to possible sources of ignition, or that cranes or other equipment will comply with the requirements for the design and installation of electrical equipment in hazardous areas.

The master may therefore have to insist on precautions additional to those set out in this chapter. Such precautions could include restricted vehicular access, removable barriers, additional fire fighting equipment and control of sources of ignition, together with restrictions on the movement of goods and operation of cargo handling equipment.

2.8 WEATHER PRECAUTIONS

2.8.1 Wind conditions

Most chemical vapours are heavier than air, so cargo vapours released during loading, gas freeing or accidental spills may concentrate in lower areas on deck, especially in conditions with little or no wind. Strong wind may create low pressure on the lee side of deckhouses or other structures, and thereby cause vapour to be carried in that direction. Personnel should be alert to either possibility.

2.8.2 Electrical storms

During electrical storms in the immediate vicinity of the ship, all operations that may evolve flammable vapours should be stopped, including tank cleaning, gas freeing and ballasting.

2.8.3 Cold weather

During cold weather, precautions should be taken to prevent equipment and systems from freezing. Attention should be given to pneumatic valves and control systems, fire lines and hydrants, steam driven equipment, cargo heating systems, pressure/vacuum valves etc. If fitted, heating arrangements should be used. Any water that has collected in a system should be drained off. Cooling water systems should be dosed with anti‑freeze or drained.

Water in a fire main or spray system should be circulated continuously, where possible. Special attention must be paid to emergency showers and eye‑wash stations to ensure the availability of facilities.

2.9 OPENINGS IN DECKHOUSES AND SUPERSTRUCTURES

Regulations require that windows and portholes in the superstructure within a certain distance of the cargo area must not open, and that openings are positioned to minimise the possibility of vapour entry. These design features must not be modified in any way.

All doors (except when being used for access), portholes and other openings should be kept closed during cargo operations. Accommodation doors that have to be kept permanently closed when in port should be marked, but they should not be locked.

Non‑essential mechanical ventilation of internal compartments should be stopped, and air conditioning units operated on closed cycle or stopped if there is any possibility of toxic or flammable vapours being drawn into the accommodation.

2.10 ENGINE AND BOILER ROOM

2.10.1 Combustion equipment

Boiler tubes, uptakes, exhaust manifolds and combustion equipment should be maintained in good condition as a precaution against funnel fires and sparks. In the event of a funnel fire, or if sparks are emitted from the funnel, cargo operations involving flammable products should be stopped and, at sea, the course should be altered to prevent sparks falling onto the cargo area.

2.10.2 Blowing boiler tubes

Funnel uptakes and boiler tubes should not be blown in port. At sea they should only be blown in conditions where soot will be blown clear of the tank deck.

2.10.3 Cargo vapour

It is important that flammable or toxic cargo vapour does not enter the engine room or boiler room spaces. Special attention should be paid to equipment in the engine room connected to the cargo area.

Contingency plans should be prepared for the possibility of an accident or an emergency that could give rise to a situation where toxic or flammable vapours are likely to enter the machinery spaces. Consideration should be given to the possible effect that such vapour entry may have on personnel or the operation of equipment. Any necessary preventive actions should be taken, such as isolating the source, closing accesses and openings, shutting down mechanical ventilation systems or main machinery, or evacuation of the spaces.

2.11 SHIP/SHORE INSULATING AND EARTHING

2.11.1 Insulating

In order to provide protection against static electrical discharge (arcing) during cargo hose connection and disconnection, the terminal should have ensured that hose strings and metal arms are fitted with an insulating flange or a single length of non‑conducting hose, to create electrical discontinuity between the ship and shore. All metal on the seaward side of the insulating section should be electrically continuous to the ship, and all metal on the landward side should be electrically continuous to the jetty earthing system.

The insulating flange or the single length of non‑conducting hose must not be short‑circuited; for example, an exposed metal flange on the seaward side of the insulating flange or hose length should not make, contact with the jetty structure directly or through hose handling equipment. An explanation of the process is given in Appendix D.3.12.

It should be noted that switching off a cathodic protection system is not a substitute for the installation of an insulating flange or a length of non‑conducting hose.

2.11.2 Ship/shore bonding cables

A ship/shore bonding cable is not effective as a safety device and may be dangerous. A ship/shore bonding cable should therefore not be used.

Although the potential dangers of using a ship/shore bonding cable are widely recognised, attention is drawn to the fact that some national and local regulations may still require a bonding cable to be connected. If a bonding cable is insisted upon, it should first be visually inspected to see, as best possible, that it is mechanically and electrically sound. The connection point for the cable should be well clear of the manifold area. There should always be a switch on the jetty in series with the bonding cable and of a type suitable for use in hazardous areas. It is important always to ensure that the switch is in the open position before connecting or disconnecting the cable. Only when the cable is properly secured and in good contact with the ship should the switch be closed. The cable should be attached before the cargo hoses are connected and removed only after the hoses have been disconnected.

2.12 HOT WORK

It is anticipated that owners and operators of chemical tankers will issue clear guidance to masters and crews on the control of hot work on board while the ship is in service. The following is intended to assist safety by indicating principal areas that should receive attention.

2.12.1 General

Hot work means any work requiring the use of electric arc or gas welding equipment, cutting burner equipment or other forms of naked flame, as well as spark generating tools. It covers all such work, regardless of where it is carried out on board a ship, including open decks, machinery rooms and the engine room.

Repair work outside the main engine room which necessitates hot work should only be undertaken when it is essential for the safety or immediate operation of the ship, and when no alternative repair procedure is possible.

Hot work outside the engine room (and in the engine room when associated with fuel or lubrication systems) must be prohibited until the requirements of national legislation and other applicable regulations have been met, safety considerations taken into account, and a hot work permit has been issued. This may involve the master, owner's superintendent, shore contractor, terminal representative and port authority as appropriate.

Hot work in port at a chemical terminal is normally prohibited. If such work becomes essential for safety or urgent operational needs, then port and terminal regulations must be complied with. Full liaison should be established with port and terminal authorities before any work is started.

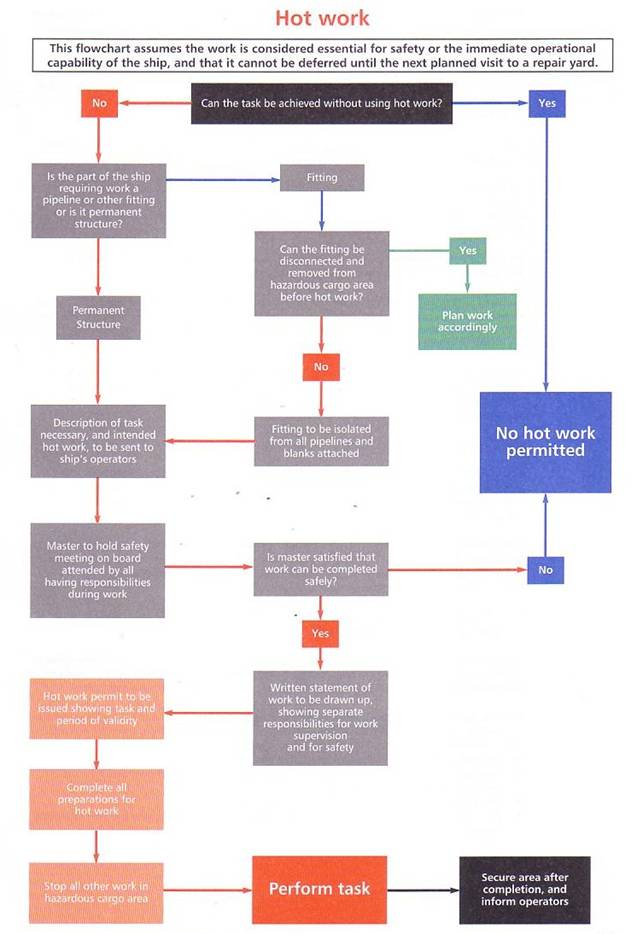

2.12.2 Assessment of hot work

The master is responsible for deciding whether the hot work is justified, and whether it can be conducted safely. Hot work in areas outside the engine room should not be started until a procedure has been discussed &nd agreed, and the master has informed the ship's owners or operators of details of the work intended.

Before hot work is started a safety meeting under the chairmanship of the master must be held, at which the planned work and the safety precautions are carefully reviewed. The meeting should be attended at least by all those who will have responsibilities in connection with the work. An agreed written plan for the work and the related safety precautions should be made. The plan must clearly and unambiguously designate one officer who is responsible for the supervision of the work, and another officer who is responsible for safety precautions and communications between all parties involved.

A flow chart to assist is shown opposite.

All personnel involved in the preparations and in the hot work operation must be briefed and instructed on their own role. They must clearly understand which officer is responsible for work supervision and which for safety precautions. A written hot work permit should be issued for each intended task. The permit should specify the duration of validity, which should not exceed a working day. An example of a hot work permit is given in Appendix P.

2.12.3 Preparations for hot work

No hot work must be undertaken inside a compartment until it has been cleaned and ventilated. Tests of the atmosphere in the compartment should indicate 21% oxygen content by volume, flammable vapour as low as possible but not more than 1% LFL, and that the compartment is free from toxic gases. It is important to continue ventilation during hot work.

No hot work should be undertaken on the open deck unless the area is free from flammable vapour and all compartments (including deck tanks) within a specified radius around the working area have been washed and freed of flammable vapour and/or inerted. Company or national regulations may give guidance on this distance. If no guidance is available, then the advice in ISGOTT should be taken into account

All sludge, cargo‑impregnated scale, sediment or other material likely to give off flammable or toxic vapour, especially when heated, should be removed from an area of at least 10 metres around all hot work. All combustible material such as insulation should either be removed or protected from heat.

Adjacent compartments should either be cleaned and gas freed to hot work standard, or freed of cargo vapour to not more than 1% LFL and kept inerted, or completely filled with water. No hot work should be undertaken in a compartment beneath a deck tank in use.

Care should be taken to ensure that no release of flammable vapour or liquid can occur from non‑adjacent compartments that are not gas free.

An adjacent fuel oil bunker tank may be considered safe if tests using a combustible gas indicator give a reading of not more than 1% LFL in the ullage space of the bunker tank, and no heat transfer through the bulkhead of the bunker tank will be caused by the hot work. No hot work should be carried out on bulkheads of bunker tanks that are in use.

All pipelines interconnecting with cargo spaces should be flushed, drained, vented and isolated from the compartment or deck area where hot work will take place.

Hot work on pipelines and valves should only be permitted when the item needing repair has been detached from the system by cold work, and the remaining system blanked off. The item to be worked on should be cleaned and gas freed to a standard that is safe for hot work, regardless of whether or not it is removed from the hazardous cargo area.

All other operations utilising the cargo or ballast system should be stopped before hot work is undertaken, and throughout the duration of the hot work. If hot work is interrupted for any reason for an extended period, hot work should not be resumed until all precautions have been rechecked and a new hot work permit has been issued.

2.12.4 Checks by officer responsible for safety during hot work

Immediately before hot work is started, the officer responsible for safety precautions should examine the area where it is to)De undertaken, and ensure that tests with a combustible gas indicator show not more than 1% LFL, and, if the work is inside an enclosed space, that the oxygen content is 21% by volume.

Adequate fire fighting equipment must be laid out and ready for immediate use. Fire watch procedures must be established for the area of hot work and in adjacent, non‑inerted spaces where the transfer of heat may create a hazard. Effective means of containing and extinguishing welding sparks and molten slag must be established.

The work area must be adequately and continuously ventilated. Flammable solvents must not be present, even for use in cleaning tools.

The frequency with which the atmosphere is to be monitored must be established. Atmospheres should be retested at regular intervals and after each break in work periods. Checks should be made for flammable vapours or liquids, toxic gases or inert gas from non‑gas free spaces.

Welding apparatus and other equipment to be used should be carefully inspected before each occasion of use to ensure that it is in good condition and, where required, correctly earthed. Special attention must be paid to electric arc equipment to ensure that:

Electrical supply connections are made in a gas free space.

Existing supply wiring is adequate to carry the electrical current demanded without overloading and consequent heating.

Flexible electric cables laid across the deck have sound insulation.

The cable route to the work site is the safest possible, only passing over gas free or inerted spaces.

2.12.5 Action on compeletion of hot work

The work area should be secured, and all special equipment used should be removed. The ship's owner or operator should be informed of the completion of all hot work allowed by the hot work permit.

2.13 USE OF TOOLS FOR SHIP'S MAINTENANCE

2.13.1 Power tools

Although grit blasting and the use of mechanically powered tools are not normally considered to fall within the definition of hot work, both these operations should only be permitted under controlled conditions. Section I of the hot work permit is suitable (see Appendix P).

The work area should not be subject to vapour release or a concentration of combustible vapours, and should be free from combustible material. The area should be gas free, and tests with a combustible gas indicator should give a reading of not more than 1% LFL. The ship must not be alongside at a terminal. There must be no cargo, bunkering, ballasting, tank cleaning or gas freeing operations in progress.

The hopper and hose nozzle of a grit blasting machine should be electrically earthed to the deck or the fitting to be blasted.

There is a risk of perforation of pipelines when grit blasting or chipping, and great care must be taken over planning such work. Cargo and inert gas pipelines should not be blasted or mechanically chipped unless the entire ship is gas free.

Adequate fire fighting equipment should be laid out and ready for immediate use.

2.13.2 Hand tools

The use of hand tools such as chipping hammers and scrapers for steel preparation and maintenance may be permitted without a hot‑work permit. Their use must be restricted to deck areas and fittings not connected to the cargo system. The work area should not be subject to vapour release or a concentration of combustible vapours. The area should be gas free and clear of combustible materials. There must be no cargo, bunkering, ballasting, tank cleaning or gas freeing operations in progress.

Work on cargo pipelines and inert gas pipelines should be subject to the same precautions as applies to power tools.

2.14 PUMPROOMS AND ENCLOSED SPACES

2.14.1 Cargo pump-rooms

Cargo pump-rooms, due to their location, design and operation, constitute a particular hazard and therefore necessitate special precautions. Cargo pump-rooms should be continuously ventilated during all cargo operations. To meet the requirements of the IBC Code, they must be fitted with mechanical ventilation systems controlled from outside. Because of the potential for the presence of cargo vapours, such spaces should be ventilated for at least 15 minutes before entering and operating the equipment inside. Only authorised personnel should enter and operate equipment in cargo pump-rooms.

Leakage of toxic liquids and escapes of toxic vapours should always be suspected, because cargo pump-rooms contain a large number of flanges, valve glands, pumps and couplings. Because pump-rooms are enclosed spaces, the concentration of toxic and flammable vapours in their atmospheres might rise to dangerous levels. In the event of pump or pipeline leakage, the pump-room atmosphere must be tested for flammable and toxic vapours appropriate to cargoes recently handled, and the pump-room should only be entered if found safe. If entry becomes essential before a safe atmosphere is established, full personal protective equipment must be worn.

Cargo liquids from minor leaks should not be allowed to accumulate in pump-room bilges. If left to lie in place, there is the possibility of unsuspected vapours from former cargoes being released when the surface of the bilge water is disturbed. In particular this could occur when a chemical which is immiscible with and heavier than water has lain under the bilge water. Additionally, when pumping out accumulated liquids there is a risk of accidentally mixing an incompatible chemical with other chemicals already in a slop tank.

Some cargoes are not allowed to be carried in tanks served by conventional below‑deck pump-rooms.

2.14.2 Enclosed spaces

Those enclosed spaces in the cargo area that are not normally entered during the operation of the ship, such as ballast tanks, cofferdams, duct keels, pipe tunnels etc., may contain flammable or toxic vapours or be oxygen deficient. They must not be entered without a permit and only entered if proper ventilation of adequate capacity is provided. Proper procedures for entering such spaces must be established and adhered to (see Chapter 3 for detailed guidance).

2.15 SHIP'S READINESS TO MOVE

At all times during discharge, loading and ballasting operations, alongside a berth or at an anchorage, the ship should be ready for departure at short notice in the event of an emergency. The ship's boilers, main engines, steering machinery, mooring equipment and other equipment essential for manoeuvring should be kept in a condition that will permit the ship to move away from the berth or anchorage at short notice in accordance with terminal and port regulations.

Repairs and other work which may immobilise the ship should not be undertaken at a berth without prior, written agreement with the terminal. It may also be necessary to obtain permission from the local port authority before carrying out such work.

2.16 NAVIGATION

Normal high standards of navigation, as described in the ICS Bridge Procedures Guide, should be maintained and any navigational restrictions (routeing, reporting requirements etc.) should be observed.

2.17 POLLUTION PREVENTION

It is the responsibility of the master and those in charge of transfer operations involving cargo or bunkers to know the applicable pollution prevention regulations, and to ensure that they are not violated. Exercises should be held to train personnel in accordance with the applicable pollution contingency plan. See Chapter 8 for emergency responses and reporting requirements.

There is increasing concern about all discharges from ships into the environment. Chapter gives detailed advice on existing and anticipated controls.

2.18 FIRE FIGHTING AND FIRE PROTECTION EQUIPMENT

Fire fighting appliances should always be kept in good working order, tested regularly, and available for immediate use at all times (see Chapter 8 and Appendix H).

2.19 HELICOPTERS

Helicopter operations in connection with chemical tankers are not routine operations, but in some ports it has become established practice to embark and disembark the pilot by helicopter, in particular on larger tankers and in bad weather. Helicopter operations must not be permitted over the cargo tank deck unless all other operations have been suspended and all cargo tank openings closed. Whenever helicopter services are used the safety measures recommended in the ICS Guide to Helicopter/Ship Operations should be taken into account.

2.20 TANK CLEANING AND GAS FREEING

2.20.1 Awareness of additional hazards

Tank cleaning and gas freeing are operations that are frequently carried out on a chemical tanker. The numerous different chemical products involved, often toxic or corrosive or both, may expose the ship's personnel to additional hazards of cargo fumes or liquid, as well as injury from working with the extra equipment. See Chapter 7 for detailed guidance.

Crew training is of the highest importance to allow understanding of the hazards involved in these operations, and the need to take necessary precautions. But it remains the master's responsibility to ensure that the personnel involved follow correct procedures and make proper use of personal protective equipment.

2.20.2 Use of tank cleaning agents

Tank cleaning agents used on a chemical tanker may be toxic, corrosive or skin sensitive. When heated they may give off irritating fumes. Personnel handling cleaning agents should wear necessary personal protective equipment.

2.21 COMMUNICATION EQUIPMENT

2.21.1 Ship's radio transmission equipment

During medium and high frequency radio transmissions significant energy is radiated, which can create a danger of incendive sparking by inducing an electrical potential in unearthed steelwork. The use of medium or high frequency main radio transmission equipment should therefore be prohibited in port and during ship to ship cargo transfers. If it is necessary to operate the ship's radio in port for maintenance the agreement of the terminal and port authorities should be sought.

Low energy transmissions of one watt or less, such as are used for VHF/UHF radios or satellite equipment, are not considered a hazard. The repositioning of satellite aerials, however, may involve the running of non‑approved drive motors within a shore hazardous zone, and consultation between the tanker and the terminal is advisable before the satellite terminal is operated.

2.21.2 Personal items

Personal equipment such as mobile telephones and radio pagers, if switched on, can be activated remotely and a hazard can be generated by the alerting or calling mechanism and, in the case of mobile telephones, by the natural response to answer the call. In view of the widespread use of such equipment, appropriate measures should be taken to prevent its use within the cargo area. Visitors should be informed that such items should only be switched on in a safe area, such as within the ship's accommodation.

Small battery powered personal items such as watches and hearing aids are not significant ignition sources when correctly used. However, portable domestic radios, electronic calculators, tape recorders, cameras and other non‑approved battery powered equipment should not be used in the cargo area or wherever flammable vapour may be encountered. When in port, local regulations may prohibit the use of any portable electrical equipement.

CHAPTER 3

ENTRY INTO ENCLOSED SPACES

General

Atmosphere in Enclosed Spaces

Requirements for Entry

Testing Before Entry

Entry into Contaminated Cargo Tanks

Entry After Confirmation of a Safe Atmosphere

.1 General

.2 Entry into cargo tanks

.3 Entry into enclosed spaces separate from the cargo system

Work in Enclosed Spaces

Rescue from Cargo Tanks and Other Enclosed Spaces

ENTRY INTO

ENCLOSED SPACES

This chapter gives guidance on procedures to follow when planning entry into an enclosed space that is not in normal daily use. On chemical tankers entry of personnel into cargo tanks is a common practice during cargo operations, and operators' instructions generally make special allowance for this. The following guidance is therefore intended to support company policy on training and operational practices, and provide some explanation of procedures.

3.1 GENERAL

When it is intended that personnel should enter or work in an enclosed space that is not in normal daily use, great care should be taken to create and maintain safe working conditions, even if the duration of the work is to be short. Many fatalities in enclosed spaces have resulted from entering such spaces without proper supervision or adherence to agreed procedures. In almost every case the fatality would have been avoided if the simple guidance in this section had been followed.

The rapid rescue of personnel who have collapsed in an enclosed space presents particular risk. It is a human reaction to go to the aid of a colleague in difficulties, but far too many additional deaths have occurred from impulsive or ill‑prepared rescue attempts. The hazards and precautions associated with entering or working in enclosed spaces are outlined in this chapter.

The normal oxygen level in fresh air is 21% by volume (but see Appendix J.7.2). Uncontaminated air with a slightly lower oxygen concentration can be breathed for some minutes before the effects become apparent. If the oxygen supply to the brain is depleted, victims will feel dizzy and have headaches before losing consciousness. This is particularly dangerous because they may not recognise that they are in danger or be capable of finding the way out of the space. They therefore become a risk to themselves and others. There is a danger of permanent brain damage after only four minutes in a very oxygen‑deficient space. A successful rescue depends upon the victim being resuscitated in the shortest possible time.

3.2 ATMOSPHERE IN ENCLOSED SPACES

When an enclosed space is left closed and unventilated for any length of time, the internal atmosphere may become unsafe to human life, either because it contains insufficient oxygen, or because it contains contaminants, or both. The oxygen content can be reduced naturally by the process of rusting or other oxidising, which absorbs oxygen from the air, or by the presence of inert gas. Contamination can come from sources such as stores. Decomposition of animal and vegetable oils and fats, a process known as putrefaction (or going off), can seriously deplete the oxygen content and evolve toxic gases, making proper ventilation of the space necessary prior to entry.

However, it is possible that an oxygen deficiency is due to the air in the space being mixed with a contaminant such as cargo vapour. Cargo vapour or inert gas should always be anticipated in cargo tanks, and leakage into adjacent enclosed spaces separated from cargo tanks by a single gas‑tight bulkhead should be suspected. Similarly, cargo vapour or inert gas should be suspected in any space containing cargo handling or inert gas equipment.

It is therefore vital that nobody ever enters an enclosed space without breathing apparatus until it has been confirmed that the atmosphere is safe and will remain so. As a general rule, enclosed spaces should not be entered unless it is absolutely necessary.

Suitable notices should be prominently displayed to warn and inform personnel about the dangers of entering enclosed spaces. Instructions should clearly explain the precautions to be taken when entering tanks or other enclosed spaces, and listing any restrictions placed upon the permitted work. Company procedures should be such that the instructions are followed.

On some ships, there is no door or hatch restricting passage from a pump-room into a duct keel. In these circumstances, the duct keel can be regarded as being ventilated by the pump-room extractor fans. Nevertheless, entry of personnel into the duct keel should be subject to a strict safety procedure involving prior notification to a responsible person.

3.3 REQUIREMENTS FOR ENTRY

Prior to allowing personnel to enter an enclosed space, an entry permit should be issued. An example of an Enclosed Space Entry Permit is provided in Appendix Q. It is recommended that it should be signed by the master or a responsible officer expressly delegated by him.

The entry permit should contain a clear indication as to its maximum period of validity (which should not exceed a normal working day), and the maximum time the space can be left unattended (which should not exceed four hours). It is critical to ensure that while personnel are within a space the levels of oxygen and any contaminants are frequently checked, and are within safe limits. If there is any doubt, suitable breathing apparatus and personal protective equipment should be worn, including a lifeline if practicable.

The responsible officer should confirm that:

The space has been thoroughly ventilated by natural or mechanical means to remove any toxic or flammable gases, and to‑ensure an adequate level of oxygen throughout the space.

All personnel entering the space are properly trained in enclosed space entry procedures, and are familiar with safety and emergency procedures; they should be aware of the ship's procedure for issuing an enclosed space entry permit.

A trained crew member is standing by at the entrance.

A reliable system of communication has been established and is understood both by those entering the space and by the crew member standing by at the entrance.

The appropriate officer of the watch on the bridge or in the cargo control room or in the engine room is aware of the enclosed‑space entry operations.

Rescue procedures are in place.

Rescue equipment (including lifelines and harnesses) and breathing apparatus are readily available, and resuscitation equipment is prepared.

The rescue procedures should clearly set out how to raise the alarm and summon assistance. Access to the space concerned, deployment of reserve equipment and communication between the emergency party and command centre should also be arranged.

In the event of emergency, under no circumstances should an attending crew member enter the space before help has arrived and the situation has been evaluated, to ensure the safety of those carrying out rescue operations.

3.4 TESTING BEFORE ENTRY

Before the space is entered it should be thoroughly ventilated. The time necessary to ensure thorough ventilation depends upon the size of the space, the capacity of the system used, the level of contamination and the efficiency of the ventilation system.

Once the space has been ventilated, the atmosphere should be checked as follows:

The oxygen content should be sampled with a suitable and reliable detector: 21% oxygen is required for entry. The principle of measuring the oxygen level in an enclosed space, and interpretation of the figure obtained, must be thoroughly understood. The content of the world's air is constant at 21% life‑sustaining oxygen, and 79% other gases which are breathable but do not themselves sustain life. Therefore, confirming that the oxygen level in a compartment is 21% ensures that there is no major component of the atmosphere that is not air. Nevertheless, this may not exclude trace volumes of toxic vapours.

If a flammable cargo vapour may be present, a combustible gas indicator should also be used. A content as low as practicable, but never more than 1% LFL, is required for entry.

If a toxic gas may be present, the correct toxic gas detector should be used to check that the level is below the safe operational exposure limit, depending on the nature of the previous contents of the space.

Ventilation

should be stopped about 10 minutes before tests are made and not restarted

until the tests are completed. Sampling the atmosphere may require the use of

breathing apparatus. A number of samples from different locations may have to

be taken before the air in the whole space can be judged safe.

Sampling and measurement should be done by personnel trained in use of the equipment, and sufficiently knowledgeable to understand the results obtained. It is vital that the correct instruments are used. A combustible gas indicator will not measure an oxygen deficiency, nor indicate the presence of toxic gas or the presence of flammable vapour in inert gas. All atmosphere testing equipment used should be of an approved type. It must be correctly maintained, prepared for use in accordance with the manufacturer's guidance, and regularly check‑tested against standard samples.

Even after a space has been made gas free and found to contain a respirable atmosphere, local pockets of gas should always be suspected. Cargo residues may be trapped in tank coatings or in residual scale. Generation of vapour should always be considered possible, even after loose scale has been removed. Hence a person moving around to different areas of a tank or compartment, or descending to the lower part after work in the upper part, should remain alert to the possible need for further tests to be made.

3.5 ENTRY INTO CONTAMINATED CARGO TANKS

Unless all necessary safety precautions can be followed, spaces should only be entered by personnel wearing breathing apparatus, appropriate protection against exposure to flammable, toxic or corrosive cargo vapours and, if practicable, a lifeline.

In chemical tankers, operational entry into cargo tanks may be required before the atmosphere is certified as safe. A documented system should exist to ensure safety throughout any operation when entry of a contaminated cargo tank, or one suspected of being contaminated, is necessary.

3.6 ENTRY AFTER CONFIRMATION OF A SAFE ATMOSPHERE

3.6.1 General

The guidance in this section is intended for all situations where it is intended to enter a space that is not in daily use by personnel on a ship, and is usually kept closed. As such, it describes procedures that will ensure personal safety in every case.

3.6.2 Entry into cargo tanks

On chemical tankers entry of personnel into cargo tanks is a more common practice than it is on oil tankers. Chemical tanker operators' instructions often make special allowance for this when describing procedures for entry into cargo tanks. The intention is to avoid causing a comparatively routine event to distract everyone's attention, but equally to ensure that adequate checks are conscientiously made and recorded. It is essential that procedures remain sufficiently stringent to ensure the safety of personnel, but are not so disruptive that busy personnel who are familiar with the work become inclined to disregard them. Operators may therefore find it expedient to issue additional instructions that achieve those twin aims with regard to cargo tank entry during cargo operations, but insist on a more particular procedure at other times and for unusual entry into other enclosed spaces. It is also essential that the ship's safety management system is robust enough to make certain that instructions are followed.

A system should be in place to indicate which cargo tanks are safe for entry by marking (or tagging) of appropriate tank entry hatches. The marking should be unambiguous, and procedures should be such that absence of the mark will forbid entry.

Restricting the issue of entry permits, such that all cargo tanks which are safe to enter are shown on one entry permit, may be found to simplify the paper administration, avoid overlapping permits and the possibility of confusion as to which permit applies to which tank. If such a system is used there must be rigorous control to ensure cancellation of existing permits, and that the atmospheres of all named tanks are correctly tested at the time of issue so that an effective extension of a period of validity does not occur by default. It will be particularly important that it is supplemented by marking of tank lids with notices indicating which tanks are safe to enter.

Inspection of cargo tanks after cleaning and before loading can require an independent surveyor to enter the tank. All relevant tank entry procedures must be observed (see Section 5.6.2.5).

3.6.3 Entry into enclosed spaces separate from the cargo system

On chemical tankers, entry into enclosed spaces separate from the cargo system should be treated with the same extreme caution as on all other ship types, and familiarity with practice in cargo tanks should not be allowed to induce any sense of complacency. In particular, it is recommended that a permit to enter is always restricted to a single compartment. Preparations for entry should be positively attended to, and pre‑positioning of rescue apparatus near the entry point is recommended.

No cofferdam, ballast tank, peak tank, fuel or lubricating oil tank, fresh water tank, duct keel not continuously open to a pump-room, void space, access trunk, or any other enclosed space should be entered unless all the precautions listed in Section 3.3 are strictly observed.

The principal danger in such spaces is that rusting has depleted the oxygen content of the atmosphere to the point where it cannot support life. However, it is also possible for cargo vapour or inert gas to leak into such spaces and the atmosphere should therefore be checked for both oxygen content and cargo vapour before entry. The IBC Code requires a capability to ventilate all such spaces where cargo or cargo vapour may accumulate.

3.7 WORK IN ENCLOSED SPACES

While personnel are inside the space, ventilation should be continued and the atmosphere monitored at regular intervals. If personnel begin to feel dizzy or unwell they should leave the space at once. Frequent atmosphere tests should be made, appropriate to the work in hand or to any change in conditions. In particular, tests should be made before each daily resumption of work. Tests should be so arranged that readings representative of the condition of the entire space are obtained.

It is a normal practice in some trades for personnel to be sent into a cargo tank being drained of animal and vegetable oils or fats, in order to sweep the final traces towards the pump suction. Familiarity with the practice should not obscure the potential dangers of cargo generated vapours or an oxygen deficient atmosphere. Use of a personal alarm should be considered.

Even after a cargo tank has been cleaned, there will always be a possibility of some cargo remaining, which could be a source of further flammable or toxic gas. Special care must therefore be taken whenever a pipeline or equipment in a tank is opened up, and additional tests should be made. If liquid or vapour escapes, the tank should be evacuated and not re‑entered until the entire atmosphere has again been found to be safe. When removing sludge, scale or sediment from an enclosed space, periodic gas tests should be undertaken, and continuous ventilation should be maintained throughout the period the space is occupied.

Whenever cargo pumps, pipelines or valves are to be opened, they should first be cleaned and gas freed. Many chemical tankers have individual cargo pumps and pipelines dedicated to each cargo tank. However, ships with fixed cargo lines that are common to several cargo tanks should take further precautions~ to isolate the tank where the work is being done. To avoid inadvertent operation, valves on all pipelines serving the space should be secured.

Hot work in an enclosed space should only be carried out when all applicable regulations and safety requirements have been met and a hot work permit has been issued (see Section 2.12).

3.8 RESCUE FROM CARGO TANKS AND OTHER ENCLOSED SPACES

It is imperative that regular drills and exercises to practice rescue from enclosed spaces are carried out and that all members of a rescue team know what is expected of them.

When personnel are in need of rescue from an enclosed space, the first action must be to raise the alarm. Rescue and resuscitation equipment should already have been prepared. Although speed is often vital in the interest of saving life, rescue operations should not be attempted until the necessary assistance has been obtained. There are many examples of lives having been lost through hasty, ill‑prepared rescue attempts.

Whenever it is suspected that an unsafe atmosphere has been a contributory factor to an accident, breathing apparatus and, where practicable, lifelines should be used by persons entering the space. A code of signals should be agreed in advance.

The officer in charge of the rescue should remain outside the space, where he can exercise the most effective control.

|

Politica de confidentialitate | Termeni si conditii de utilizare |

Vizualizari: 4315

Importanta: ![]()

Termeni si conditii de utilizare | Contact

© SCRIGROUP 2024 . All rights reserved