| CATEGORII DOCUMENTE |

| Bulgara | Ceha slovaca | Croata | Engleza | Estona | Finlandeza | Franceza |

| Germana | Italiana | Letona | Lituaniana | Maghiara | Olandeza | Poloneza |

| Sarba | Slovena | Spaniola | Suedeza | Turca | Ucraineana |

Sediment in Crude Oil by Membrane Filtration

This standard is issued under the fixed designation D 4807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval

This test method has been approved by the sponsoring committee and accepted by the Cooperating Societies in accordance with

established procedures

1. Scope

1.1 This test method covers the determination of sediment

in crude oils by membrane filtration. This test method has been

validated for crude oils with sediments up to about 0.15 mass

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability

of regulatory limitations prior to use.

1.3 The accepted unit of measure for this test method is

mass

2. Referenced Documents

2.1 ASTM Standards:

D 473 Test Method for Sediment in Crude Oils and Fuel

Oils by the Extraction Method

D 2892 Test Method for Distillation of Crude Petroleum

(15-Theoretical Plate Column)3

D 4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

D 4177 Practice for Automatic Sampling of Petroleum and

Petroleum Products

D 4377 Test Method for Water in Crude Oils by Pontentiometric

Karl Fischer Titration

3. Summary of Test Method

3.1 A portion of a representative crude oil sample is

dissolved in hot toluene and filtered under vacuum through a

0.45-m porosity membrane filter. The filter with residue is

washed, dried, and weighed to give the final result.

4. Significance and Use

4.1 A knowledge of the sediment content of crude oil is

important both in the operation of the refinery and in the

buying and selling of crude oils.

5. Apparatus

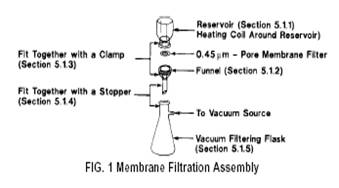

5.1 Reservoir and Filter Support Assemblyan assembly

designed to hold 47-mm diameter filters was used in the

development of this test method (see Fig. 1).

5.1.1 Filter Reservoircapable of holding from about 250

mL of solvent. The lower part of the reservoir has a 40-mm

inside diameter and is designed to secure the 47-mm diameter

filter against the filter support. The reservoir can be jacketed to

facilitate heating the reservoir and sample during filtering.

NOTE 1Use of a glass reservoir should minimize the effect of static

electricity when filtering.

5.1.2 Filter Support/Funnelsupport base for the filter has

a porous scintered glass center section about 40 to 43 mm in

diameter. The support base is designed to fit securely against

the reservoir holding the filter in place over the porous section.

The stem of the funnel portion should be long enough to extend

down into the filter flask such that the end is below the outlet

for the vacuum.

5.1.3 Clamp Assemblyspring or screw type clamp to

secure the reservoir to the filter support. The clamp should be

tight enough to prevent the solvent from leaking through at the

junction between the glass and filter membrane. The exterior

dimensions of the reservoir and support/funnel are designed to

facilitate clamping the two pieces together.

5.1.4 Rubber Stoppera single-hole, capable of holding the

lower stem of the filter support/funnel securely onto the

filtering flask.

5.1.5 Vacuum Filtering Flask, 500 mL or larger.

5.2 Membrane Filter, nylon membrane filter, 47 mm in

diameter with 0.45-m pore size.

5.3 Oven, capable of maintaining a temperature of 105

2C.

5.4 Vacuum Pump, capable of reducing and maintaining the

pressure at 200 mm Hg (-80 KPA) during the filtering.

5.5 Analytical Balance, capable of measuring to the nearest

0.0001 g.

5.6 Heating Coil for Filter Assembly copper tubing (

in. diameter) wound around the reservoir on the filter apparatus

and connected to a circulating bath to maintain the oil in the

reservoir at 90 2C (see Fig. 1). Alternative methods of

heating the reservoir such as heating tape or glass thermal

jacket could also be used.

5.7 Mixer a nonaerating, high-speed mixer capable of

meeting the homogenization efficiency test in Annex A1. Large

volume dynamic mixing systems such as those used with

automatic crude oil sampling receptacles are also acceptable

providing they comply with Annex A1.

6. Reagents

6.1 Purity of ReagentsReagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Committee

on Analytical Reagents of the American Chemical Society,

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

6.2 Toluene (Warning, Flammable).

NOTE 2Warning: Flammable.

7. Sampling, Test Specimens

7.1 Sampling, is defined as all the steps required to obtain an

aliquot of the contents of any pipe, tank, or other system, and

to place the sample into the laboratory test container. The

laboratory test container and sample volume shall be of

sufficient dimensions and volume to allow mixing as described

in 7.3.1. Mixing is required to properly disperse sediment as

well as any water present in the sample.

The following mixers have been found satisfactory for samples under 300 mL:

Ultra Turrax Model

TP 18/10, available from Tekmar Co.,

Brinkman Polytron Model PT 35, available from Brinkman Instruments, Inc.,

NJ.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical

Society,

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole,

and National

MD.

7.2 Laboratory SampleUse only representative samples

obtained as specified in Practice D 4057 or D 4177 for this test

method. Analyze samples within two weeks after taking the

sample. Retaining samples longer may affect the results.

7.3 Test SamplesThe following sample handling procedure

shall apply.

7.3.1 Mix the test sample of crude oil at room temperature

in the original container immediately (within 15 min) before

analysis to ensure complete homogeneity. A test sample drawn

directly from a large volume dynamic mixing system analyze

within 15 min or else remix as follows:

NOTE 3Analysis should follow mixing as soon as possible. The

15-min interval mentioned above is a general guideline which may not

apply to all crudes, especially some light crudes which do not hold water

in suspension for even this short a time.

7.3.2 Mixing of the sample should not increase the temperature

of the sample more than 10C, or a loss of water may

occur and this affects sample composition. The type of mixer

depends on the quantity of crude. Before any unknown mixer

is used, the specifications for the homogenization test, Annex

A, must be met. The mixer must be re-evaluated following any

changes in the type of crude, quantity of crude, or shape of the

sample container.

7.3.3 For small test sample volumes, 50 to 300 mL, a

nonaerating, high-speed, shear mixer is required. Use the

mixing time, mixing speed, and height above the bottom of the

container found to be satisfactory in Annex A1. Clean and dry

the mixer between samples.

8. Procedure

8.1 Prepare nylon filters by heating in an oven at 105C for

15 min. Cool and store the dried filters in a desiccator (without

desiccant) until needed. Use only new filters.

8.2 Weigh the filter immediately before use to the nearest

0.0001 g.

8.3 Using tweezers, place the membrane filter on the center

of the filter support, which is mounted on the filtering flask

with a rubber stopper. Attach the reservoir to the filter support

and clamp it securely.

8.4 Connect the heating coil to the circulating bath and

place the coil around the lower part of the reservoir. Set the

temperature of the circulating bath so as to maintain the oil in

the reservoir at 90 2C.

NOTE 4Care should be taken not to overheat the reservoir so as to

cause evaporation of the toluene and glazing of the filter.

8.5 Into a 200-mL beaker, weigh 10 g of a thoroughly mixed

sample (see Section 7) to the nearest 0.0001 g. Add 100 mL of

toluene to the beaker and heat the mixture with stirring to 90

2C. Maintain the temperature at 90 2C for about 15 min to

dissolve any wax in the crude.

8.6 Start the vacuum pump and adjust the vacuum to 200

mm Hg. Carefully pour the sample mixture into the filter

reservoir in three portions. Generally the sample should filter in

10 to 15 min. If the nature of the crude or the amount of

sediment causes the filtration to proceed extremely slowly (for

example, filtering times greater than 30 min), reduce the

sample size to 5 g or less and repeat the test. Keep the volume

of toluene at 100 mL.

NOTE 5If the filtration of a given crude typically takes less than 10

min and the sample stays at 90 2C during this time, then external

heating of the filter reservoir may not be necessary.

8.7 Before the last portion of sample has completely filtered,

wash the reservoir and filter with 50 mL of hot toluene

(90C) until no oil is visible on the filter. With the vacuum on,

leave the filter on the apparatus for 2 min.

8.8 Disassemble the filter apparatus by removing the clamp

and reservoir. Inspect the condition of the filter. If the filter has

been properly mounted, it may not be necessary to wash the

edges after disassembly. However, if upon removing the

reservoir dark spots are observed around the edge of the filter

further washing is necessary. With the vacuum on, use a

dropper to wash the filters edges with hot toluene (90C).

8.9 If the filter is completely or partially covered with black

or dark brown crude oil residue after the washing step above,

then discard the filter and repeat the test with a smaller sample

size

NOTE 6Normally the color of the sediment on the filter is gray or light

tan. A black or deep brown colored deposit on the filter is indicative of

incomplete washing.

8.10 If the appearance of the filter is acceptable (as in 8.9)

then carefully remove it and place it in an oven at 105C for 15

min. Cool in a desiccator and reweigh to the nearest 0.0001 g.

9. Calculation

9.1 Calculate the mass percent of sediment as follows:

Mass %

G

S

where

G gain in mass of filter, g, and

S sample mass, g,

10. Report

10.1 Report results to the nearest 0.001 % as the mass

percent of sediment by membrane filtration. The test report

shall reference this Test Method D 4807 as the procedure used.

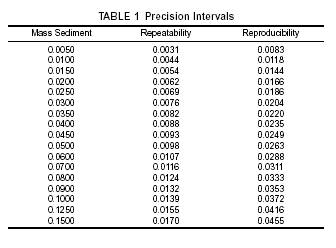

11. Precision and Bias

11.1 RepeatabilityThe difference between successive test

results, obtained by the same operator with the same apparatus

D

under constant operating conditions on identical test material,

would in the long run, in the normal and correct operation of

test method, exceed the following values in only one case in

twenty (see Table 1).

X

where X is sample mean

11.2 ReproducibilityThe difference between two single

and independent results obtained by different operations working

in different laboratories on identical test material would, in

the long run, in the normal and correct operation of the test

method, exceed the following values only in one case in twenty

(see Table 1).

X

where X is sample mean

11.3 BiasThe data generated during the development of

this test method showed that more sediment is recovered from

crude oil using this test method compared to the results of Test

Method D 473.

12. Keywords

12.1 apparatus; crude oil; membrane filtration; procedure;

reagents; sampling; sediment

ANNEX

(Mandatory Information)

A1. HOMOGENIZATION EFFICIENCY OF UNKNOWN MIXERS

A1.1 The homogenization efficiency of each unknown

mixer shall be evaluated before use. The grade of crude oil, the

sample size, and the sample container expected to be used with

the mixer should be used in this test. The specifications of this

test should be met before running this test method and any

changes in the mixing procedure should be re-evaluated by this

test. The mixing efficiency is measured by following the water

content as described in Test Method D 4377. The crude oil used

in this test should be dry (less than 0.1 % water), otherwise

perform a preliminary distillation to remove the water as

described in Test Method D 2892.

A1.2 Weigh the sample container to the nearest 0.01 g. Fill

the container halfway (or the level normally used) with the dry

crude. Immerse the mixer into the crude with the bottom of the

mixer 5 mm above the bottom of the container and mix the

crude at the speed and for the amount of time you expect to

use. Suggested mixing time is between 1 and 5 min at 5 to 7000

r/min. Immediately determine the water content in duplicate

(see Test Method D 4377) of the dry crude. Obtain the average

of the duplicate results.

A1.3 Weigh the crude and container to the nearest 0.01 g.

Immerse the mixer into the crude as in A1.2. Knowing the

weight of the crude, add enough water to increase the water

content 1 % above the base level found in A1.2. From a

water-filled syringe previously weighed (nearest 0.1 mg), inject

the water below the surface of the crude near the inlet to the

mixer. Reweigh the syringe (to the nearest 0.1 mg) and

determine the amount of water added. Any oil on the needle

should be wiped off before weighing. Mix the sample in the

same manner as in A1.2. Determine the water content of the

crude immediately after mixing. Sample the crude just below

the liquid level.

A1.4 Without additionally mixing the crude, determine the

water content of the crude 15 and 30 min after the initial

mixing in A1.3.

A1.5 Remix the sample in the same manner as A1.2.

Immediately after mixing, determine the water content in

duplicate

A1.6 The water contents of the crude determined in A1.3,

A1.4, and A1.5 minus the base determined in A1.2 should

agree within 0.05 % absolute of the added water and to each

other. If they do not agree, this test should be repeated while

changing the mixing time, the mixing speed, or the height of

the mixer in the crude, or a combination thereof until these

conditions are met.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views

known to the ASTM Committee on Standards,

This standard is copyrighted by ASTM,

reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at 610-832-9585

(phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (https://www.astm.org).

Esta norma se emite bajo la designacin fija D 4807; el nmero que sigue la designacin inmediatamente indica el ao de adopcin original o, en el caso de revisin, el ao de ltima revisin. Un nmero en parntesis indica el ao de la ltima revisin. Un epsilon del exponente (e) indica un cambio editorial desde la ltima revisin.

Este mtodo de la prueba ha sido aceptado por el comit patrocinando y habido aceptado por las Sociedades Cooperando de acuerdo con los procedimientos establecidos.

1. Alcance

1.1 este mtodo de la prueba cubre la determinacin de sedimento

en aceites crudos por filtracin de la membrana. Este mtodo de la prueba ha sido

validado para aceites crudos con sedimentos a a aproximadamente 0.15 masa

1.2 esta norma no pretende para dirigirse todos del

la seguridad involucra, si cualquiera, asociado con su uso. Es el

la responsabilidad del usuario de esta norma para establecer apropiado

seguridad y la salud practica y determina la pertinencia

de prior de las limitaciones regulador para usar.

1.3 la unidad aceptada de medida para este mtodo de la prueba es

masa

2. los Documentos de Referencias

2.1 Normas de ASTM:

D 473 Mtodo de la Prueba para el Sedimento en Aceites Crudos y Combustible

Aceites por el Extracto Method2

D 2892 Mtodo de la Prueba para la Destilacin de Petrleo Crudo

(15-Theoretical plato Column)3

D 4057 Prctica para Manual que Prueba de Petrleo y

Petrleo Products3

D 4177 Prctica por el Probar Automtico de Petrleo y

Petrleo Products3

D 4377 Mtodo de la Prueba para el Agua en Aceites Crudos por Pontentiometric

Karl Fischer Titration3

3. el resumen de Mtodo de la Prueba

3.1 una porcin de una muestra de aceite cruda representativa es

disuelto en tolueno caliente y se filtr bajo el vaco a travs de un

0.45-m filtro de membrana de porosidad. El filtro con residuo es

lavado, sec, y pes para dar el resultado final.

4. la importancia y Uso

4.1 un conocimiento del volumen del sedimento de aceite crudo es

importante ambos en el funcionamiento de la refinera y en el

comprando y vendiendo de aceites crudos.

5. el aparato

5.1 depsito y Apoyo del Filtro Asamblea-una asamblea

diseado para sostener 47-mm filtros del dimetro se us en el

desarrollo de este mtodo de la prueba (vea Fig. 1) .4

5.1.1 filtro Depsito-capaz de tenencia de aproximadamente 250

mL de solvente. La parte ms baja del depsito tiene un 40-mm

dentro del dimetro y se disea para afianzar el 47-mm dimetro

fltrese contra el apoyo del filtro. El depsito puede ser jacketed a

facilite calentando el depsito y pruebe durante filtrarse.

NOTE que 1-Use de un depsito de vidrio deben minimizar el efecto de esttica

electricidad al filtrarse.

5.1.2 base de Support/Funnel-apoyo de filtro para el filtro tiene

una scintered vidrio centro seccin porosa aproximadamente 40 a 43 mm en

dimetro. La base de apoyo se disea para encajar firmemente contra

el depsito que sostiene el filtro en lugar encima de la seccin porosa.

El tallo de la porcin del embudo debe ser mucho tiempo bastante para extenderse

baje en el frasco del filtro tal que el extremo est debajo de la toma de corriente

para el vaco.

5.1.3 Asamblea-primavera de la alerta o alerta de tipo de tornillo a

afiance el depsito al apoyo del filtro. La alerta debe ser

firme bastante para impedir al solvente gotear a travs de al

unin entre el vidrio y membrana del filtro. El exterior

las dimensiones del depsito y apoyo / embudo se disean a

facilite sujetando los dos pedazos juntos.

5.1.4 Tapn de caucho un solo el agujero, capaz de tenencia el

tallo ms bajo del filtro apoyo embudo firmemente hacia el

frasco filtrndose.

5.1.5 vaco que se Filtra Frasco, 500 mL o ms grande.

5.2 Filtro de la membrana, filtro de membrana de niln, 47 mm en

dimetro con 0.45-m poro size.5

5.3 horno, capaz de mantener una temperatura de 105 6

2C.

5.4 Bomba del vaco, capaz de reducir y mantener el

presione a 200 mm Hg (-80 KPA) durante el filtrarse.

5.5 Equilibrio analtico, capaz de medir al ms cercano

0.0001 g.

5.6 Rollo de la calefaccin para la Asamblea del Filtro - la tubera cobriza (1.8 -

en. dimetro) la herida alrededor del depsito en el aparato del filtro

y conect a un bao circulante para mantener el aceite en el

depsito a las 90 6 2C (vea Fig. 1). los mtodos Alternativos de

calentando el depsito como cinta calorfica o vidrio termal

la chaqueta tambin podra usarse.

5.7 Mixer6-a nonaerating, el mezclador de gran velocidad capaz de

encontrndose la prueba de eficacia de homogenization en Anexo A1. Grande

volumen los sistemas mezclando dinmicos como aqullos usados con

aceite crudo automtico que prueba receptculos tambin es aceptable

proporcionando ellos obedecen Anexo A1.

6. los reactivos

6.1 pureza de qumicos de calidad de Reactivo-reactivo ser

usado en todas las pruebas. A menos que por otra parte indic, se piensa que

todos los reactivos conformarn a las especificaciones del Comit

en los Reactivos Analticos de la Sociedad Qumica americana,

donde las tales caracterstica tcnicas son que available.7 Otras calidades pueden ser

us, con tal de que se determina primero que el reactivo es de

pureza suficientemente alta para permitir su uso sin disminuir el

exactitud de la determinacin.

6.2 Toluene (Advirtiendo, Inflamable).

NOTE 2-Warning: Inflamable.

7. probando, Espcimenes de la Prueba,

7.1 que prueban, se define como todos los pasos exigi obtener un

alcuota de los volmenes de cualquier caera, tanque, o otro sistema, y

|

Politica de confidentialitate | Termeni si conditii de utilizare |

Vizualizari: 2244

Importanta: ![]()

Termeni si conditii de utilizare | Contact

© SCRIGROUP 2025 . All rights reserved