| CATEGORII DOCUMENTE |

| Bulgara | Ceha slovaca | Croata | Engleza | Estona | Finlandeza | Franceza |

| Germana | Italiana | Letona | Lituaniana | Maghiara | Olandeza | Poloneza |

| Sarba | Slovena | Spaniola | Suedeza | Turca | Ucraineana |

Electricity generation

Electricity generation is the first process in the delivery of electricity to consumers. The other three processes are electric power transmission, electricity distribution and electricity retailing.

Electricity generation

The importance of dependable electricity generation, transmission and distribution was revealed when it became apparent that electricity was useful for providing heat, light and power for human activities. Decentralised power generation became possible when it was recognised that alternating current electric power lines can transport electricity at low cost across great distances by taking advantage of the ability to transform the voltage using power transformers.

Electricity has been generated for the purpose of powering human technologies for at least 120 years from various sources of potential energy. The first power plants were run on wood, while today we rely mainly on petroleum, natural gas, coal, hydroelectric and nuclear power and a small amount from hydrogen, solar energy, tidal harnesses, and wind generators.

Electricity demand

The demand for electricity can be met in two different ways. The primary method thus far has been for public or private utilities to construct large scale centralized projects to generate and transmit the electricity required to fuel growing economies. Many of these projects have unpleasant environmental effects such as air or radiation pollution and the flooding of large areas of land.

Increasingly, distributed generation is seen as an alternate way to supply the electrical demand close to the users. Smaller, distributed projects can:

Methods of generating electricity

Methods for transforming other power into

electrical power

Methods for transforming other power into

electrical power

Rotating turbines attached to electrical generators produce most commercially available electricity. Turbines may be driven by using steam, water, wind or other fluids as an intermediate energy carrier. The most common usage is by steam in fossil fuel power plants or nuclear power plants, and by water in hydroelectric dams. Small mobile generators are often driven by diesel engines, especially on ships, remote building sites or for emergency standby.

Fuel cells produce electricity using a variety of chemicals and are seen by some people to be the most likely source of power in the long term, especially if hydrogen can be used as the feedstock. However, hydrogen is usually only an energy carrier, and must be formed by some other power source.

Primary energy sources used in electrical power generation

World Electricity Generation

The world relies

mainly on coal and natural gas for power. The high capital requirements of

nuclear power and the fear of its dangers have prevented the ordering of new

nuclear power plants in

Steam turbines can be powered using steam produced from geothermal sources, solar energy, or Nuclear reactors, which use the energy created by the fission of radioactive plutonium or uranium to generate heat. Nuclear power plants often use a primary and secondary steam circuit to add an additional layer of protection between the location of the nuclear fuel and the generator room.

Hydroelectric power plants use water flowing directly through the turbines to power the generators. Tidal harnesses use the force of the moon on bodies of water to spin a turbine. Wind turbines use wind to turn turbines that are hooked up to a generator.Pumped-storage hydroelectricity is used to level demands on the power grid.

Power generation by thermonuclear fusion has been suggested as a possible way of generating electricity; currently a number of technical obstacles and environmental concerns stand in the way, but if realized fusion might provide a relatively clean and safe source of electrical power. The construction of a large experimental reactor (ITER) is expected to commence in 2005-2006.

Improving efficiency

Co-generation (combined heat and power) plants combine the generation of electricity and heat using solar power, fossil fuels, syngas, biomass, or biogas as a fuel source. These plants can achieve efficiencies as high as 80%, but many of these plants being built today only expect to achieve stated maximum 55% efficiency. Heated steam turns a turbine, and then excess heat is distributed for space heating in buildings, industrial processes or green house heating. Whole communities can benefit from heat distributed through a district heating scheme.

The ability to achieve tri-generation using fossil fuels or solar energy to generate heat, electricity and evaporative cooling exists. These combined power plants have the best energy conversion ratio after hydroelectric plants. Small photovoltaic arrays, windmills and bicycles hooked up to a turbine can all be used to generate mobile electricity.

Ownership and reform of electricity generation market

Electricity reform around the world is de-coupling electricity generation from the regulated monopoly elements of transmission and electricity distribution; see electricity market. The generation and distribution of electricity is managed by either privately owned or state owned public utilities. In recent years some governments have started to privatise or corporatise these utilities as part of a move to introduce market forces to monopolies. The New Zealand Electricity Market is a typical example.

DEFINITIONS

Crude oil is a naturally occurring mixture consisting predominantly of hydrocarbons that exists in liquid phase in natural underground reservoirs and is recoverable as liquids at typical atmospheric conditions of pressure and temperature. Crude oil has a viscosity no greater than 10 000 mPa.s (centipoises) at original reservoir conditions; oils of greater viscosity are included in Chapter 4 - Natural Bitumen and Extra-Heavy Oil.

Natural gas liquids (NGLs) are hydrocarbons that exist in the reservoir as constituents of natural gas but which are recovered as liquids in separators, field facilities or gas-processing plants. Natural gas liquids include (but are not limited to) ethane, propane, butanes, pentanes, natural gasoline and condensate; they may include small quantities of non-hydrocarbons.

If reserves/resources/production/consumption of NGLs exist but cannot be separately quantified, they are included (as far as possible) under crude oil.

In the tables the following definitions apply to both crude oil and natural gas liquids:

Proved amount in place is the tonnage originally occurring in known natural reservoirs which has been carefully measured and assessed as exploitable under present and expected local economic conditions with existing available technology.

Proved recoverable reserves is the tonnage within the proved amount in place that can be recovered in the future under present and expected economic conditions with existing available technology.

Estimated additional amount in place is the tonnage additional to the proved amount in place that is of foreseeable economic interest. Speculative amounts are not included.

Estimated additional reserves recoverable is the tonnage within the estimated additional amount in place which geological and engineering information indicates with reasonable certainty might be recovered in the future.

R/P (reserves/production) ratio is calculated by dividing proved recoverable reserves at the end of 1999 by production in that year. The resulting figure is the time in years that the proved recoverable reserves would last if production were to continue at the 1999 level.

COAL (INCLUDING LIGNITE)

COAL (INCLUDING LIGNITE)

Coal, Oil and Gas are called 'fossil fuels' because they have been formed from the fossilised remains of prehistoric plants and animals.

In writing the commentary to accompany the latest analysis of proved recoverable reserves of coal, there is the opportunity to provide a narrative that deals with the results on two very distinct levels. On one level, a review in terms of reserves, their location, notable reassessments from past surveys and the relationship between reserves and production/consumption, regional balance and trade flows.

But there is also a broader debate what do proved recoverable reserves of coal mean in terms of energy resources for today and tomorrow, in terms of energy availability and coal use?

We have seen some very significant changes within the coal industry since the last WEC Survey published in September 1998. Many of these changes reflect broader global issues, including trade competitiveness, global concentration, and market restructuring (particularly at country level, with continuing shifts from command to market economies for some major players).

The point was made in the 1998 Survey that the size of the resource base is not the restraining factor for coal to be able to continue supplying a considerable portion of world primary energy demand. At that time the restraining factor on coals participation in the supply of the worlds primary energy demand was identified as a question of the development of production facilities and infrastructure.

Looking now both with hindsight and from an assessment of the contemporary policy setting, the issues currently facing coal are much more in the context of international, regional and national environmental policy conditions relating to the use of coal.

In dealing with the specific reserves of coal, there is little change in the total world figures, just a slight overall increase on the previous Survey. This is a predictable outcome, given the maturity of the industry and the large amount of reserves relative to current rates of exploitation. The rough and ready explanation of a production level showing that exploitation can continue at current levels in excess of 200 years is correct in arithmetic terms, but of little consequence or value given the size of this number. The world is not going to run out of physically-available supplies of coal.

Any limit on coal use will not be imposed by a limit on the availability of physical resources of coal but coal use could face limits and restrictions in the future which would affect the availability and price of energy. These changes in the relative market value of coal compared with other energy sources will impact on recoverable reserves when the economic impact is taken into account by individual countries when assessing their coal reserves.

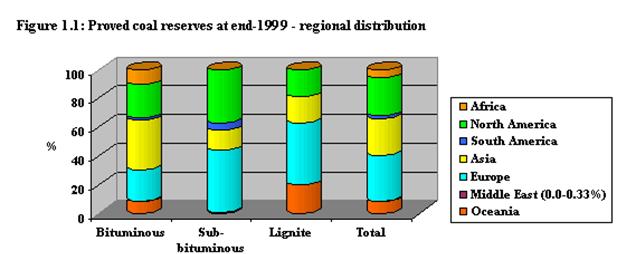

Within the total world reserves, there was a

slight adjustment between the three primary categories with the bituminous

increasing by 2%, while sub-bituminous declined by 1% and lignite reserves by

around 3% below the previous recorded levels.

Within the total world reserves, there was a

slight adjustment between the three primary categories with the bituminous

increasing by 2%, while sub-bituminous declined by 1% and lignite reserves by

around 3% below the previous recorded levels.

The top ten countries accounted for 95% of the reserves of bituminous coal which was equal to 53% of total coal reserves. These same ten countries also held over 85% of the sub-bituminous and lignite reserves. In total, these top ten countries on a reserves basis held just over 90% of the total reported coal reserves at the end of 1999.

On a geographic basis,

Both North America and

Total coal reserves held by

European reserves are dominated by two countries:

Significant changes between these results and those of the previous

Survey are recorded by nine countries:

Looking beyond the issue of coal reserves, a number of the key indicators within the coal industry have shown significant change over the past three years.

Ownership of coal-producing enterprises has changed significantly. On one level, the trend which had just commenced in the second half of the last decade the withdrawal of the oil majors from the strategic coal production investments undertaken in the wake of the oil shocks of the 1970s turned into a flood of disposals. Very limited coal-producing assets remained in the hands of oil companies by the end of 2000. Of those assets remaining, most have been on the market, with the special circumstances of the individual assets being the primary reason for the failure to conclude this chapter in the history of coal in the hands of oil companies.

In addition to the departure of the oil majors from coal production, industry concentration has been pursued by a number of the major coal-producing companies. A number of global mining houses and global coal specialists increased their coal portfolio, taking advantage of the lower asset values reflecting the poor market returns for coal over the last decade, and encouraging many smaller operations to exit from the sector. Further industry concentration is expected to continue within the industry.

In the period since the 18th Survey, the most significant

production adjustment has occurred in

The

Traded coal on a global level continues to expand. While the long-term

importers remain in the trade and continue to increase demand other

countries have emerged as significant markets as their domestic coal industry

is further exposed to a competitive coal market.

Imports into the

This is a powerful reminder of the role of transport in the cost-competitive delivery of coal into most global markets and as a key factor in determining the export source of the coal.

The second half of the 1990s has seen the

consolidation of

Specific attributes of some coals have also aided the development of

coal production and heightened interest in reserves located in countries such

as

This highlights the importance of a qualitative assessment of reserves that takes into account environmental issues which are still evolving on a global level. Different standards across different countries (from low to high) suggest reported reserves would also reflect these differences, to the degree that externalities have been and will be incorporated into the reserves assessment.

Allied to this is the work of the US Geological Survey (USGS) to create a reliable worldwide coal-quality and related information database. The goal for the World Coal Quality Inventory (WoCQI) is to generate reliable, internally consistent coal quality analyses for all major coal-producing countries.

Accurate information on coal, particularly information on coal properties and characteristics, is required to make informed decisions regarding the best use of indigenous resources, international import needs and export opportunities, domestic and foreign policy objectives, technology transfer opportunities, foreign investment prospects, environmental and health assessments, and by-product use and disposal issues.

The two major uses for coal steel production and electricity generation continue to be at the heart of development for most countries seeking economic growth. Coal supplies around 23% of the total global primary energy demand, around 38% of total world electricity production and is an essential input for steel production via the BOF process, which accounts for almost 70% of total world steel production.

But will this remain what are the risks and constraints facing coal in continuing a business-as-usual outlook?

The year 2000 took energy and the users of this resource on the next phase of the combined political and economic roller coaster. At the mid-point of 2000, North Sea Brent crude oil was quoted at US$ 30.18 (27 June), an 80% increase over the price one year earlier.

Coal prices, particularly in the spot and short-term market, have moved strongly upwards as the oil price has remained in the US$ mid-twenties band, encouraging fuel switching away from oil and gas where the energy market has the capacity to substitute fuel inputs or energy sources. The skyrocketing of natural gas prices stimulated demand for coal in a market with considerable coal-burning capacity.

The good news is that coal has been available to respond to the market situation flexibility still remains in the 'system' to switch fuels in many countries. Coal-fired generating capacity was available to enable fuel substitution to occur to alleviate the market pressure. However, this option is being slowly closed off in a number of important European markets as coal-fired electricity capacity is taken out of service.

Will the coal option continue to be available to respond in the future under similar circumstances?

For the coal production side of the debate, the answer is simple: medium- and long-term availability of coal for the international market is assured, with a diverse range of sources and suppliers.

But the delivery and use of coal will rely on other elements of the overall electricity production chain and, importantly, the policy conditions under which markets will be required to operate at the regional and national levels.

What

are the factors political, economic, environmental and social that will

affect coals future involvement in the energy market?

What

are the factors political, economic, environmental and social that will

affect coals future involvement in the energy market?

Deregulation of markets and the establishment of new, higher hurdles of environmental performance have been found to be fun and rewarding in the playground of energy surplus, which is the circumstance of most developed countries. It is not a luxury available to, or shared by, many countries seeking to enhance living conditions and standards to a basic level for all citizens.

Where deregulation of the electricity markets has been undertaken or commenced in developed countries, the market has always featured adequate or excess generating capacity (including reserve capacity). This makes life simple in the short- and medium-term and creates unrealistic expectations for the future. Future capacity investments are not certain and will rely on major firms being created out of market concentration to be able to absorb/cover the financial/commercial risks of such developments, guaranteeing oligopolistic behaviour at best within the deregulated market in the future.

Can governments pick and choose the energy mix they want based on their goal for achieving certain environmental outcomes? The political issue of climate change and the desire of some governments to reduce greenhouse gas (GHG) emissions is an area of great potential change for energy, and for coal in particular.

The coal industry production and consumption will change because of the emerging political circumstances and new market conditions. Coal will need to reduce its environmental footprint.

Some countries have introduced (or indicated their intention to introduce in the near future) support policies for alternative energy sources and mandated energy market shares for coals competitors.

Coal is the most carbon-intensive of the fossil fuels at the point of combustion. Improved coal technology and efficiency are consistent with the GHG objectives of the United Nations Framework Convention on Climate Change (UNFCCC) (and the Kyoto Protocol) and can provide significant benefits, in both developed and developing countries. Deployment of these technologies will support the continuation of coal in the global energy mix.

Technology can deliver solutions to the GHG emissions for coal significant research is now focussed on the challenges of tomorrow. Advanced technologies are being pursued for the conversion of coal into energy - and to enhance the capture and sequestering of carbon by-products.

The US Department of Energy (DOE) has a major research programme to

develop new carbon sequestration technologies, which capture and store gases

that enhance the natural 'greenhouse effect.' The DOE programme

objective is to reduce the expense of carbon sequestration to US$ 10 or less

per ton by 2015, equivalent to about one US cent per  kilowatt

hour on the average electricity bill.

kilowatt

hour on the average electricity bill.

Technology advances will ensure coal remains a critical part of the energy equation. Other policy and market responses will underwrite low-cost measures to address the environmental issues of climate change and GHG emissions to the atmosphere.

Coal will remain part of the energy resource endowment, possibly with a greater role in energy delivery as a key element of the energy bridge to the future under the conditions of sustainable development. The World Energy Assessment recently highlighted the global energy challenge to provide greater access to clean and affordable fuels and electricity to the two billion people still dependent on traditional fuels with serious health consequences. Coal can assist in meeting this challenge with cleaner technologies ensuring both that energy needs can be satisfied and improved environmental outcomes attained.

DEFINITIONS

Proved amount in place is the tonnage that has been carefully measured and assessed as exploitable under present and expected local economic conditions with existing available technology.

Maximum depth of deposits and minimum seam thickness relate to proved amount in place.

Proved recoverable reserves are the tonnage within the proved amount in place that can be recovered (extracted from the earth in raw form) under present and expected local economic conditions with existing available technology.

Estimated additional amount in place is the indicated and inferred tonnage additional to the proved amount in place. It includes estimates of amounts which could exist in unexplored extensions of known deposits or in undiscovered deposits in known coal-bearing areas, as well as amounts inferred through knowledge of favourable geological conditions. Speculative amounts are not included.

Estimated additional reserves recoverable is the tonnage within the estimated additional amount in place which geological and engineering information indicates with reasonable certainty might be recovered in the future.

TABLE NOTES

The tables cover bituminous coal (including anthracite), sub-bituminous coal and lignite. Data for peat are given in Chapter 8. There is no universally accepted system of demarcation between coals of different rank and what is regarded as sub-bituminous coal tends to vary from one country to another. Moreover, if it is not isolated as such, sub-bituminous is sometimes included with bituminous and sometimes with lignite.

There are no internationally agreed standards for estimating coal reserves and, although the WEC attempts to establish precisely worded definitions, it is a matter of judgement for each country to determine the quantities that, in its opinion, meet these definitions.

CRUDE OIL AND NATURAL GAS LIQUIDS

The period 1996-1999 was marked by large variations in the price of

crude oil. The price per barrel started to slide in late 1997 and finally

bottomed out at $10/bbl at the end of 1998. Two factors can be held responsible

for this decline: a slowdown in the growth of oil demand and a supply surplus.

In 1997, the economic crisis in

Figure 2.1: Evolution of Oil Price ($/bbl) (Dated Brent) 1997/2001

Source: IEA

The debate over reserves

During the 1990s, the debate over oil reserves/resources generated controversy between the 'pessimists' and the 'optimists'.

The 'pessimists' advocate the position that the world is finite and so are its recoverable oil resources. To make their argument, they rely on descriptive statistics and base their conclusions on the statistical study of past discoveries, considering all oil and gas fields to be static objects (with no evolution in the size of initially recoverable reserves). The pessimists believe that all of the oil-bearing regions worth exploring have already been explored and that the big fields have already been discovered, ergo future discoveries will be small. They claim that the official figures for proven reserves have been overestimated for some regions and that world oil production is currently at its optimum - or can be expected to reach its optimum in the medium term - and will decrease steadily thereafter.

The 'optimists' hold a dynamic concept of reserves and believe that a method based solely on applying descriptive statistics to past discoveries will only yield a partial image of actual potential. The volumes of exploitable oil and gas are closely correlated to technological advances, technical costs and the price of the barrel of crude or the cubic metre of gas. For example, it is estimated that today only 35% to 40% of the oil present in discovered fields is recovered. According to an optimist, any improvement in this recovery rate - even if by only one point - allows the industry to tap substantial additional reserves. Similarly, the boundary between conventional and non-conventional hydrocarbons is not fixed, but has continued to shift regularly over time. For instance, optimists note that it is now both feasible and profitable to exploit fields at water depths exceeding 1 000 metres, which was still thought to be impossible 15 years ago.

The evolution of hydrocarbon resources from 1996 to 1999

Between the 1998 WEC Survey of Energy Resources and the present Survey, proved recoverable reserves of hydrocarbons (as reported by WEC Member Committees and other sources) remained fairly stable overall: oil reserves fell by 2.7% while gas reserves went up by 2.8%

In the case of oil, Africa and South America were the major regions to

experience growth (of around 4% in each case) whereas Africa (+13%) and

Some of the arguments advanced by pessimists are supported by the fact that fewer 'giant' fields (with ultimate recoverable reserves exceeding 500 million bbls for oil and 3 tcf for gas) are being discovered. In the 1960s, about one hundred such fields were found, but only about thirty came to light in the 1980s. What happened to giant hydrocarbon discoveries in the 1990s?

To consider oil

first, 29 giant fields were discovered, including 7 at water depths greater

than 1 000 metres. In

As for gas, 29 giant

gas fields were located, including 8 in the Middle East (Pars and Azadegan in

All in all, the 1990s matched the 1980s for giant discoveries, with the very deep offshore sector making a powerful contribution to this stability.

The 1990s, or the advent of deep offshore activity

During the 1990s, even more than in the 1980s, the discoveries of new

oil fields were concentrated in a small number of countries. In point of fact,

during the period 1990-1999, 50% of new fields were concentrated in 10 of the

95 countries where discoveries were made. These new fields were primarily

located in regions long known or recently found to be oil-rich:

Source: IHS Energy

The Roncador field in the

Deep offshore: an ongoing technological challenge

In 1978, the greatest production depth was 300 m. By 1998, deepwater

production was under way at 1 800 m, a record set by Petrobras in the

Figure 2.4: Deep Offshore Production Records

(source: IFP)

Today, the potential represented by deep offshore resources has not yet been clearly determined. Sedimentary areas lying in over 200 m of water represent nearly 55 million km of sedimentary basins, or four times the conventional offshore surface area. The permits that have already been delivered only cover 5% of this area.

Deep-offshore conditions present certain characteristics (high pressures, low temperatures, large water-depth range, the constant presence of ocean currents, etc.) that are radically different from those typifying conventional offshore operations.

It did not take long for the industry to realize that conventional offshore solutions could not be applied at greater water depths, and that new concepts would have to be developed in order to tap the 10 billion toe of proven deep offshore reserves.

The entire exploration-to-production chain was reviewed and adapted to greater water depths:

The development and use of (3D) seismic was intensified.

Innovative drilling and production structures were designed. Because these structures could not be installed on the seabed at such great depths, FPSO (Floating Production Storage and Offloading) and TLP (Tension Leg Platform) systems were developed.

Efforts were made to come up with new materials for the flexibles (able to withstand high pressures at great water depths, etc.).

Horizontal and multibranch wells came into general use, reducing the number of wells.

Figure 2.5: Key deep offshore technologies

(source: IFP)

For oil companies, the next target depth is 3 000 m. Meeting this objective constitutes a major industry challenge for the next 5 to 10 years.

The transition from deep offshore to ultra-deep offshore will require higher allocations of R&D resources. Beyond a certain limit, it will not be possible to extrapolate from existing solutions, so new ones will have to be found and proven appropriate and reliable.

OIL SHALE

If a technology can be developed to economically recover oil from oil

shale, the potential is tantalisingly enormous. If the containing organic

material could be converted to oil, the quantities would be far beyond all

known conventional oil reserves. Oil shale in great quantities exists

worldwide: including in

The term 'oil shale' is a misnomer. It does not contain oil nor is it commonly shale. The organic material is chiefly kerogen, and the 'shale' is usually a relatively hard rock, called marl. Properly processed, kerogen can be converted into a substance somewhat similar to petroleum. However, it has not gone through the 'oil window' of heat (natures way of producing oil) and therefore, to be changed into an oil-like substance, it must be heated to a high temperature. By this process the organic material is converted into a liquid, which must be further processed to produce an oil which is said to be better than the lowest grade of oil produced from conventional oil deposits, but of lower quality than the upper grades of conventional oil.

There are two conventional approaches to oil shale processing. In one, the shale is fractured in-situ and heated to obtain gases and liquids by wells. The second is by mining, transporting, and heating the shale to about 450oC, adding hydrogen to the resulting product, and disposing of and stabilising the waste. Both processes use considerable water. The total energy and water requirements together with environmental and monetary costs (to produce shale oil in significant quantities) have so far made production uneconomic. During and following the oil crisis of the 1970s, major oil companies, working on some of the richest oil shale deposits in the world in western United States, spent several billion dollars in various unsuccessful attempts to commercially extract shale oil.

Oil shale has been burned directly as a very low grade, high

ash-content fuel in a few countries such as

With increasing numbers of countries experiencing declines in

conventional oil production, shale oil production may again be pursued. One

project is now being undertaken in north-eastern

Perhaps oil shale will eventually find a place in the world economy, but the energy demands of blasting, transport, crushing, heating and adding hydrogen, together with the safe disposal of huge quantities of waste material, are large. On a small scale, and with good geological and other favourable conditions, such as water supply, oil shale may make a modest contribution but so far shale oil remains the 'elusive energy'.

Nuclear power plants provide about 17 percent of the world's

electricity. Some countries depend more on nuclear power for electricity than

others. In

The dome-shaped

containment building at the Shearon Harris Nuclear Power Plant near

Have you ever wondered how a nuclear power plant works or how safe nuclear power is? In this article, we will examine how a nuclear reactor and a power plant work. We'll explain nuclear fission and give you a view inside a nuclear reactor.

Uranium

Uranium is a fairly common element on Earth, incorporated into the planet during the planet's formation. Uranium is originally formed in stars. Old stars exploded, and the dust from these shattered stars aggregated together to form our planet. Uranium-238 (U-238) has an extremely long half-life> (4.5 billion years), and therefore is still present in fairly large quantities. U-238 makes up 99 percent of the uranium on the planet. U-235 makes up about 0.7 percent of the remaining uranium found naturally, while U-234 is even more rare and is formed by the decay of U-238. (Uranium-238 goes through many stages or alpha and beta decay to form a stable isotope of lead, and U-234 is one link in that chain.)

Uranium-235 has an interesting property that makes it useful for both nuclear power production and for nuclear bomb production. U-235 decays naturally, just as U-238 does, by alpha radiation. U-235 also undergoes spontaneous fission a small percentage of the time. However, U-235 is one of the few materials that can undergo induced fission. If a free neutron runs into a U-235 nucleus, the nucleus will absorb the neutron without hesitation, become unstable and split immediately. See How Nuclear Radiation Works for complete details.

Nuclear Fission

The animation below shows a uranium-235 nucleus with a neutron approaching from the top. As soon as the nucleus captures the neutron, it splits into two lighter atoms and throws off two or three new neutrons (the number of ejected neutrons depends on how the U-235 atom happens to split). The two new atoms then emit gamma radiation as they settle into their new states. There are three things about this induced fission process that make it especially interesting:

The probability of a U-235 atom capturing a neutron as it passes by is fairly high. In a reactor working properly (known as the critical state), one neutron ejected from each fission causes another fission to occur.

The process of capturing the neutron and splitting happens very quickly, on the order of picoseconds (1x10-12 seconds).

An incredible amount of energy is released, in the form of heat and gamma radiation, when a single atom splits. The two atoms that result from the fission later release beta radiation and gamma radiation of their own as well. The energy released by a single fission comes from the fact that the fission products and the neutrons, together, weigh less than the original U-235 atom. The difference in weight is converted directly to energy at a rate governed by the equation E = mc2.

Something on the order of 200 MeV (million electron volts) is released by the decay of one U-235 atom (if you would like to convert that into something useful, consider that 1 eV is equal to 1.602 x 10-12 ergs, 1 x 107 ergs is equal to 1 joule, 1 joule equals 1 watt-second, and 1 BTU equals 1,055 joules). That may not seem like much, but there are a lot of uranium atoms in a pound of uranium. So many, in fact, that a pound of highly enriched uranium as used to power a nuclear submarine or nuclear aircraft carrier is equal to something on the order of a million gallons of gasoline. When you consider that a pound of uranium is smaller than a baseball, and a million gallons of gasoline would fill a cube 50 feet per side (50 feet is as tall as a five-story building), you can get an idea of the amount of energy available in just a little bit of U-235.

In order for these properties of U-235 to work, a sample of uranium must be enriched so that it contains 2 percent to 3 percent or more of uranium-235. Three-percent enrichment is sufficient for use in a civilian nuclear reactor used for power generation. Weapons-grade uranium is composed of 90-percent or more U-235.

Inside a Nuclear Power Plant

To build a nuclear reactor, what you need is some mildly enriched uranium. Typically, the uranium is formed into pellets with approximately the same diameter as a dime and a length of an inch or so. The pellets are arranged into long rods, and the rods are collected together into bundles. The bundles are then typically submerged in water inside a pressure vessel. The water acts as a coolant. In order for the reactor to work, the bundle, submerged in water, must be slightly supercritical. That means that, left to its own devices, the uranium would eventually overheat and melt.

To prevent this, control rods made of a material that absorbs neutrons are inserted into the bundle using a mechanism that can raise or lower the control rods. Raising and lowering the control rods allow operators to control the rate of the nuclear reaction. When an operator wants the uranium core to produce more heat, the rods are raised out of the uranium bundle. To create less heat, the rods are lowered into the uranium bundle. The rods can also be lowered completely into the uranium bundle to shut the reactor down in the case of an accident or to change the fuel.

The uranium bundle acts as an extremely high-energy source of heat. It heats the water and turns it to steam. The steam drives a steam turbine, which spins a generator to produce power. In some reactors, the steam from the reactor goes through a secondary, intermediate heat exchanger to convert another loop of water to steam, which drives the turbine. The advantage to this design is that the radioactive water/steam never contacts the turbine. Also, in some reactors, the coolant fluid in contact with the reactor core is gas (carbon dioxide) or liquid metal (sodium, potassium); these types of reactors allow the core to be operated at higher temperatures.

Outside a Nuclear Power Plant

Once you get past the reactor itself, there is very little difference between a nuclear power plant and a coal-fired or oil-fired power plant except for the source of the heat used to create steam.

Electricity for homes and businesses comes from this generator at the Shearon Harris plant. It produces 870 megawatts.

Pipes carry steam to power the generator at

the power plant.

Pipes carry steam to power the generator at

the power plant.

The reactor's pressure vessel is typically housed inside a concrete liner that acts as a radiation shield. That liner is housed within a much larger steel containment vessel. This vessel contains the reactor core as well the hardware (cranes, etc.) that allows workers at the plant to refuel and maintain the reactor. The steel containment vessel is intended to prevent leakage of any radioactive gases or fluids from the plant.

Finally, the

containment vessel is protected by an outer concrete building that is strong

enough to survive such things as crashing jet airliners. These secondary

containment structures are necessary to prevent the escape of

radiation/radioactive steam in the event of an accident like the one at

Steam rises from the cooling tower at the Harris plant.

Workers in the control room at the nuclear power plant can keep an eye on the nuclear reactor and take action if something goes wrong.

Uranium-235 is not the only possible fuel for a power plant. Another fissionable material is plutonium-239. Plutonium-239 can be created easily by bombarding U-238 with neutrons -- something that happens all the time in a nuclear reactor.

Subcriticality, Criticality and Supercriticality

When a U-235 atom splits, it gives off two or three neutrons (depending on the way the atom splits). If there are no other U-235 atoms in the area, then those free neutrons fly off into space as neutron rays. If the U-235 atom is part of a mass of uranium -- so there are other U-235 atoms nearby -- then one of three things happens:

If, on average, exactly one of the free neutrons from each fission hits another U-235 nucleus and causes it to split, then the mass of uranium is said to be critical. The mass will exist at a stable temperature. A nuclear reactor must be maintained in a critical state.

If, on average, less than one of the free neutrons hits another U-235 atom, then the mass is subcritical. Eventually, induced fission will end in the mass.

If, on average, more than one of the free neutrons hits another U-235 atom, then the mass is supercritical. It will heat up.

For a nuclear bomb, the bomb's designer wants the mass of uranium to be very supercritical so that all of the U-235 atoms in the mass split in a microsecond. In a nuclear reactor, the reactor core needs to be slightly supercritical so that plant operators can raise and lower the temperature of the reactor. The control rods give the operators a way to absorb free neutrons so the reactor can be maintained at a critical level.

The amount of uranium-235 in the mass (the level of enrichment) and the shape of the mass control the criticality of the sample. You can imagine that if the shape of the mass is a very thin sheet, most of the free neutrons will fly off into space rather than hitting other U-235 atoms. A sphere is the optimal shape. The amount of uranium-235 that you must collect together in a sphere to get a critical reaction is about 2 pounds (0.9 kg). This amount is therefore referred to as the critical mass. For plutonium-239, the critical mass is about 10 ounces (283 grams).

What Can Go Wrong

Well-constructed nuclear power plants have an important advantage when it comes to electrical power generation -- they are extremely clean. Compared with a coal-fired power plant, nuclear power plants are a dream come true from an environmental standpoint. A coal-fired power plant actually releases more radioactivity into the atmosphere than a properly functioning nuclear power plant. Coal-fired plants also release tons of carbon, sulfur and other elements into the atmosphere (see this page for details).

Unfortunately, there are significant problems with nuclear power plants:

Mining and purifying uranium has not, historically, been a very clean process.

Improperly functioning

nuclear power plants can create big problems. The

Spent fuel from nuclear power plants is toxic for centuries, and, as yet, there is no safe, permanent storage facility for it.

Transporting nuclear

fuel to and from plants poses some risk, although to date, the safety record in

the

These problems have

largely derailed the creation of new nuclear power plants in the

In the last forty years we have seen nuclear energy take its place as a major source of electricity worldwide, on both economic and resource strategy grounds. Today the question of global warming focuses attention on the extent to which nuclear energy offsets it, and may increasingly do so in the future.

The publication of three recent reports suggest that the question of nuclear's future is no longer controversial among international energy experts, but can be answered very positively.

Depending on your

point of view, it is either amusing or tragic to witness the verbal gymnastics

in international gatherings such as last years COP5 in

At present nuclear power displaces nearly two and a half billion tonnes per year of carbon dioxide emissions worldwide relative to coal, that is to say if the 2400 TWh of nuclear electricity in 1999 were produced by coal, 2.4 billion tonnes would be the extra CO2 arising.

Every 22 tonnes of uranium used for electricity saves the emission of about one million tonnes of carbon dioxide, relative to coal.

Nuclear energy now provides over 16 percent of the world's total electricity. It has the potential to contribute much more, especially if greenhouse concerns lead to a change in the relative economic advantage of nuclear electricity, or its ethical desirability.

In

Of course there is enormous appeal in the proposition that we should develop 'renewable' technologies to harness more of the sun and the wind. I fully support such developments, and hope that we can do rather better than the official 2% target. However, we need also to recognise that such sources are intrinsically unsuited to providing base-load electricity, which requires reliable and continuous supply on a gigawatt-day (million kilowatt day), rather than kilowatt-hour, scale.

Load curve for Victorian grid on a winter day

Much electricity

demand is for reliable, continuous supply which simply cannot be met on any

significant scale from intermittent and occasional sources such as wind and

solar photovoltaics. For instance,

In providing base-load electricity, uranium competes mainly with coal. I suggest that the large-scale use of natural gas for this purpose raises some major ethical issues in squandering such a valuable energy resource and hydrocarbon feedstock in that way.

As you will be aware, in most countries electricity demand is increasing much faster than overall energy demand. This is partly because in many applications other than heating, using electricity increases efficiency and so means using less energy overall.

Public debate about the virtues and threats of nuclear energy is about options for producing electricity. None of the options is without some risk or side effects.

The obvious fact that nuclear power doesn't produce carbon dioxide is increasingly relevant to its role in the world's energy mix. In fact of course there is likely to be some carbon dioxide produced at various stages in the front end and the back end of the nuclear fuel cycle, the amount depending on what assumptions you make about the energy intensiveness of enrichment and the efficiency and source of that energy input. The amount is trivial.

For several overseas

countries, meeting their national greenhouse gas emission targets would be

impossible without their substantial use of nuclear power for electricity

generation. Since 1980

Fuel assembly ready for reactor

click to enlarge

Reactor operation has been getting steadily better, with the result that nuclear electricity output has been rising much faster than the number and capacity of the plants producing it.

The reactor core is loaded with fuel, which is usually uranium enriched to 3.5% to more than 4% U-235, the fissile isotope. The fuel is typically in the form of ceramic pellets of UO2, assembled inside zircalloy or stainless steel tubes (as shown above). In the reactor this is surrounded by coolant and moderator. The moderator slows down the fast neutrons from the nuclear fission chain reaction so that they are more likely to cause further fission in U-235 atoms. The fission reaction produces heat which is used to produce steam to drive turbines.

In engineering terms, nuclear fuel burn-up has increased substantially since the 1970s and in new plants is now over 1000 kilowatt hours per gram of uranium* in a light water reactor, using normal enriched fuel. This gives about 500,000 MJ/kg of natural uranium, compared with around 25 MJ/kg for good steaming coal, ie about 20,000 times the energy from the same amount of good steaming coal.

* 45 MWD/kg U

Notwithstanding

Everything is made of atoms. Atoms bind together into molecules. So a water molecule is made from two hydrogen atoms and one oxygen atom bound together into a single unit. Because we learn about atoms and molecules in elementary school, we understand and feel comfortable with them. In nature, any atom you find will be one of 92 types of atoms, also known as elements. So every substance on Earth -- metal, plastics, hair, clothing, leaves, glass -- is made up of combinations of the 92 atoms that are found in nature. The Periodic Table of Elements you see in chemistry class is a list of the elements found in nature plus a number of man-made elements.

Inside every atom are three subatomic particles: protons, neutrons and electrons. Protons and neutrons bind together to form the nucleus of the atom, while the electrons surround and orbit the nucleus. Protons and electrons have opposite charges and therefore attract one another (electrons are negative and protons are positive, and opposite charges attract), and in most cases the number of electrons and protons are the same for an atom (making the atom neutral in charge). The neutrons are neutral. Their purpose in the nucleus is to bind protons together. Because the protons all have the same charge and would naturally repel one another, the neutrons act as 'glue' to hold the protons tightly together in the nucleus.

The number of protons in the nucleus determines the behavior of an atom. For example, if you combine 13 protons with 14 neutrons to create a nucleus and then spin 13 electrons around that nucleus, what you have is an aluminum atom. If you group millions of aluminum atoms together you get a substance that is aluminum -- you can form aluminum cans, aluminum foil and aluminum siding out of it. All aluminum that you find in nature is called aluminum-27. The '27' is the atomic mass number -- the sum of the number of neutrons and protons in the nucleus. If you take an atom of aluminum and put it in a bottle and come back in several million years, it will still be an atom of aluminum. Aluminum-27 is therefore called a stable atom. Up to about 100 years ago, it was thought that all atoms were stable like this.

Many atoms come in different forms. For example, copper has two stable forms: copper-63 (making up about 70 percent of all natural copper) and copper-65 (making up about 30 percent). The two forms are called isotopes. Atoms of both isotopes of copper have 29 protons, but a copper-63 atom has 34 neutrons while a copper-65 atom has 36 neutrons. Both isotopes act and look the same, and both are stable.

In this figure, the yellow particles are orbital electrons, the blue particles are neutrons and the red particles are protons.

The part that was not understood until about 100 years ago is that certain elements have isotopes that are radioactive. In some elements, all of the isotopes are radioactive. Hydrogen is a good example of an element with multiple isotopes, one of which is radioactive. Normal hydrogen, or hydrogen-1, has one proton and no neutrons (because there is only one proton in the nucleus, there is no need for the binding effects of neutrons). There is another isotope, hydrogen-2 (also known as deuterium), that has one proton and one neutron. Deuterium is very rare in nature (making up about 0.015 percent of all hydrogen), and although it acts like hydrogen-1 (for example, you can make water out of it) it turns out it is different enough from hydrogen-1 in that it is toxic in high concentrations. The deuterium isotope of hydrogen is stable. A third isotope, hydrogen-3 (also known as tritium), has one proton and two neutrons. It turns out this isotope is unstable. That is, if you have a container full of tritium and come back in a million years, you will find that it has all turned into helium-3 (two protons, one neutron), which is stable. The process by which it turns into helium is called radioactive decay.

Certain elements are naturally radioactive in all of their isotopes. Uranium is the best example of such an element and is the heaviest naturally occurring radioactive element. There are eight other naturally radioactive elements: polonium, astatine, radon, francium, radium, actinium, thorium and protactinium. All other man-made elements heavier than uranium are radioactive as well.

adioactive decay is a natural process. An atom of a radioactive isotope will spontaneously decay into another element through one of three common processes:

Alpha decay

Beta decay

Spontaneous fission

In the process, four different kinds of radioactive rays are produced:

Alpha rays

Beta rays

Gamma rays

Neutron rays

Americium-241, a radioactive element best known for its use in smoke detectors, is a good example of an element that undergoes alpha decay. An americium-241 atom will spontaneously throw off an alpha particle. An alpha particle is made up of two protons and two neutrons bound together, which is the equivalent of a helium-4 nucleus. In the process of emitting the alpha particle, the americium-241 atom becomes a neptunium-237 atom. The alpha particle leaves the scene at a high velocity -- perhaps 10,000 miles per second (16,000 km/sec).

If you were looking at an individual americium-241 atom, it would be impossible to predict when it would throw off an alpha particle. However, if you have a large collection of americium atoms, then the rate of decay becomes quite predictable. For americium-241, it is known that half of the atoms decay in 458 years. Therefore, 458 years is the half-life of americium-241. Every radioactive element has a different half-life, ranging from fractions of a second to millions of years, depending on the specific isotope. For example, americium-243 has a half-life of 7,370 years.

Tritium (hydrogen-3) is a good example of an element that undergoes beta decay. In beta decay, a neutron in the nucleus spontaneously turns into a proton, an electron, and a third particle called an antineutrino. The nucleus ejects the electron and antineutrino, while the proton remains in the nucleus. The ejected electron is referred to as a beta particle. The nucleus loses one neutron and gains one proton. Therefore, a hydrogen-3 atom undergoing beta decay becomes a helium-3 atom. If you click on the 'Go' button in the figure below, you can see the neutron change.

In spontaneous fission, an atom actually splits instead of throwing off an alpha or beta particle. The word 'fission' means 'splitting.' A heavy atom like fermium-256 undergoes spontaneous fission about 97 percent of the time when it decays, and in the process, it becomes two atoms. For example, one fermium-256 atom may become a xenon-140 and a palladium-112 atom, and in the process it will eject four neutrons (known as 'prompt neutrons' because they are ejected at the moment of fission). These neutrons can be absorbed by other atoms and cause nuclear reactions, such as decay or fission, or they can collide with other atoms, like billiard balls, and cause gamma rays to be emitted.

Neutron radiation can be used to make nonradioactive atoms become radioactive; this has practical applications in nuclear medicine. Neutron radiation is also made from nuclear reactors in power plants and nuclear-powered ships and in particle accelerators, devices used to study subatomic physics.

In many cases, a nucleus that has undergone alpha decay, beta decay or spontaneous fission will be highly energetic and therefore unstable. It will eliminate its extra energy as an electromagnetic pulse known as a gamma ray. Gamma rays are like X-rays in that they penetrate matter, but they are more energetic than X-rays. Gamma rays are made of energy, not moving particles like alpha and beta particles.

While on the subject of various rays, there are also cosmic rays bombarding the Earth at all times. Cosmic rays originate from the sun and also from things like exploding stars. The majority of cosmic rays (perhaps 85 percent) are protons traveling near the speed of light, while perhaps 12 percent are alpha particles traveling very quickly. It is the speed of the particles, by the way, that gives them their ability to penetrate matter. When they hit the atmosphere, they collide with atoms in the atmosphere in various ways to form secondary cosmic rays that have less energy. These secondary cosmic rays then collide with other things on Earth, including humans. We get hit with secondary cosmic rays all of the time, but we are not injured because these secondary rays have lower energy than primary cosmic rays. Primary cosmic rays are a danger to astronauts in outer space.

Although they are 'natural' in the sense that radioactive atoms naturally decay and radioactive elements are a part of nature, all radioactive emissions are dangerous to living things. Alpha particles, beta particles, neutrons, gamma rays and cosmic rays are all known as ionizing radiation, meaning that when these rays interact with an atom they can knock off an orbital electron. The loss of an electron can cause problems, including everything from cell death to genetic mutations (leading to cancer), in any living thing.

Because alpha particles are large, they cannot penetrate very far into matter. They cannot penetrate a sheet of paper, for example, so when they are outside the body they have no effect on people. If you eat or inhale atoms that emit alpha particles, however, the alpha particles can cause quite a bit of damage inside your body.

Beta particles penetrate a bit more deeply, but again are only dangerous if eaten or inhaled; beta particles can be stopped by a sheet of aluminum foil or Plexiglas. Gamma rays, like X-rays, are stopped by lead.

Neutrons, because they lack charge, penetrate very deeply, and are best stopped by extremely thick layers of concrete or liquids like water or fuel oil. Gamma rays and neutrons, because they are so penetrating, can have severe effects on the cells of humans and other animals. You may have heard at some point of a nuclear device called a neutron bomb. The whole idea of this bomb is to optimize the production of neutrons and gamma rays so that the bomb has its maximum effect on living things.

As we have seen, radioactivity is 'natural,' and we all contain things like radioactive carbon-14. There are also a number of man-made nuclear elements in the environment that are harmful. Nuclear radiation has powerful benefits, such as nuclear power to generate electricity and nuclear medicine to detect and treat disease, as well as significant dangers.

Uranium

Uranium is a very heavy (dense) metal which can be used as an abundant source of concentrated energy.

It occurs in most rocks in concentrations of 2 to 4 parts per million and is as common in the earth's crust as tin, tungsten and molybdenum. It occurs in seawater, and could be recovered from the oceans if prices rose significantly.

It was discovered in 1789 by Martin Klaproth, a German chemist, in the mineral called pitchblende. It was named after the planet Uranus, which had been discovered eight years earlier.

Uranium was apparently formed in super novae about 6.6 billion years ago. While it is not common in the solar system, today its radioactive decay provides the main source of heat inside the earth, causing convection and continental drift.

The high density of uranium means that it also finds uses in the keels of yachts and as counterweights for aircraft control surfaces (rudders and elevators), as well as for radiation shielding.

The Uranium Atom

On a scale arranged according to the increasing mass of their nuclei, uranium is the heaviest of all the naturally-occurring elements (Hydrogen is the lightest). Uranium is 18.7 times as dense as water.

Like other elements, uranium occurs in slightly differing forms known as 'isotopes'. These isotopes (16 in the case of uranium) differ from each other in the number of particles (neutrons) in the nucleus. 'Natural' uranium as found in the earth's crust is a mixture largely of two isotopes: uranium-238 (U-238), accounting for 99.3% and U-235 about 0.7%.

The isotope U-235 is important because under certain conditions it can readily be split, yielding a lot of energy. It is therefore said to be 'fissile' and we use the expression 'nuclear fission'

Meanwhile, like all radioactive isotopes, it decays. U-238 decays very slowly, its half-life being the same as the age of the earth (4500 million years). This means that it is barely radioactive, less so than many other isotopes in rocks and sand. Nevertheless it generates 0.1 watts/tonne and this is enough to warm the earth's core.

Energy from the uranium atom

The nucleus of the U-235 atom comprises 92 protons and 143 neutrons (92 + 143 = 235). When the nucleus of a U-235 atom captures a neutron it splits in two (fissions) and releases some energy in the form of heat, also two or three additional neutrons are thrown off. If enough of these expelled neutrons cause the nuclei of other U-235 atoms to split, releasing further neutrons, a fission chain reaction can be achieved. When this happens over and over again, many millions of times, a very large amount of heat is produced from a relatively small amount of uranium.

It is this process, in effect 'burning' uranium, which occurs in a nuclear reactor. The heat is used to make steam to produce electricity.

Inside the reactor

In a nuclear reactor the uranium fuel is assembled in such a way that a controlled fission chain reaction can be achieved. The heat created by splitting the U-235 atoms is then used to make steam which spins a turbine to drive a generator, producing electricity.

Nuclear power stations and fossil-fuelled power stations of similar capacity have many features in common. Both require heat to produce steam to drive turbines and generators. In a nuclear power station, however, the fissioning of uranium atoms replaces the burning of coal or gas .

The chain reaction that takes place in the core of a nuclear reactor is controlled by rods which absorb neutrons and which can be inserted or withdrawn to set the reactor at the required power level.

The fuel elements are surrounded by a substance called a moderator to slow the speed of the emitted neutrons and thus enable the chain reaction to continue. Water, graphite and heavy water are used as moderators in different types of reactors.

Because of the kind of fuel used (ie the concentration of U-235, see below), if there is a major uncorrected malfunction in a reactor the fuel may melt, but it cannot explode like a bomb.

A typical 1000

megawatt (MWe) reactor can provide enough electricity for a modern city of

close to one million people. About 35 such nuclear reactors could provide

Uranium and Plutonium

Whereas the U-235 atom is 'fissile', the U-238 atom is said to be 'fertile'. This means that it can capture one of the neutrons which are flying about in the core of the reactor and become (indirectly) plutonium-239, which is fissile. Pu-239 is very much like U-235, in that it fissions when hit by a neutron and this also yields a lot of energy.

Because there is so much U-238 in a reactor core (most of the fuel), these reactions occur frequently, and in fact about one third of the energy yield comes from 'burning' Pu-239.

But sometimes a Pu-239 atom simply captures a neutron without splitting, and it becomes Pu-240. Because the Pu-239 is either progressively 'burned' or becomes Pu-240, the longer the fuel stays in the reactor the more Pu-240 is in it.*

* The significance of this is that when the spent fuel is removed after about three years, the plutonium in it is not suitable for making weapons but can be recycled as fuel.

From uranium ore to reactor fuel

Uranium ore can be mined by underground or open-cut methods, depending on its depth. After mining, the ore is crushed and ground up. Then it is treated with acid to dissolve the uranium, which is then recovered from solution.

Uranium may also be mined by in situ leaching (ISL), where it is dissolved from the orebody in situ and pumped to the surface.

The end product of the mining and milling stages, or of ISL, is uranium oxide concentrate (U3O8). This is the form in which uranium is sold.

Before it can be used in a reactor for electricity generation, however, it must undergo a series of processes to produce a useable fuel.

For most of the world's reactors, the next step in making a useable fuel is to convert the uranium oxide into a gas, uranium hexafluoride (UF6), which enables it to be enriched. Enrichment increases the proportion of the uranium-235 isotope from its natural level of 0.7% to 3 - 4%. This enables greater technical efficiency in reactor design and operation, particularly in larger reactors, and allows the use of ordinary water as a moderator.

After enrichment, the UF6 gas is converted to uranium dioxide (UO2) which is formed into fuel pellets. These fuel pellets are placed inside thin metal tubes which are assembled in bundles to become the fuel elements for the core of the reactor.

For reactors which use natural uranium as their fuel (and hence which require graphite or heavy water as a moderator) the U3O8 concentrate simply needs to be refined and converted directly to uranium dioxide.

Spent reactor fuel is removed, stored, and then either reprocessed or disposed of underground

Gasoline(fuel)

n the

Gasoline is known as an aliphatic hydrocarbon. In other words, gasoline is made up of molecules composed of nothing but hydrogen and carbon arranged in chains. Gasoline molecules have from seven to 11 carbons in each chain. Here are some common configurations:

H H H H H H H

| | | | | | |

H-C-C-C-C-C-C-C-H Heptane

| | | | | | |

H H H H H H H

H H H H H H H H

| | | | | | | |

H-C-C-C-C-C-C-C-C-H Octane

| | | | | | | |

H H H H H H H H

H H H H H H H H H

| | | | | | | | |

H-C-C-C-C-C-C-C-C-C-H Nonane

| | | | | | | | |

H H H H H H H H H

H H H H H H H H H H

| | | | | | | | | |

H-C-C-C-C-C-C-C-C-C-C-H Decane

| | | | | | | | | |

H H H H H H H H H H

Typical molecules found in gasoline

When you burn gasoline under ideal conditions, with plenty of oxygen, you get carbon dioxide (from the carbon atoms in gasoline), water (from the hydrogen atoms) and lots of heat. A gallon of gasoline contains about 132x106 joules of energy, which is equivalent to 125,000 BTU or 36,650 watt-hours:

If you took a 1,500-watt space heater and left it on full blast for a full 24-hour day, that's about how much heat is in a gallon of gas.

Gasoline is made from crude oil. The crude oil pumped out of the ground is a black liquid called petroleum. This liquid contains hydrocarbons, and the carbon atoms in crude oil link together in chains of different lengths.

It turns out that hydrocarbon molecules of different lengths have different properties and behaviors. For example, a chain with just one carbon atom in it (CH4) is the lightest chain, known as methane. Methane is a gas so light that it floats like helium. As the chains get longer, they get heavier.

The first four chains -- CH4 (methane), C2H6 (ethane), C3H8 (propane) and C4H10 (butane) -- are all gases, and they boil at -161, -88, -46 and -1 degrees F, respectively (-107, -67, -43 and -18 degrees C). The chains up through C18H32 or so are all liquids at room temperature, and the chains above C19 are all solids at room temperature.

The different chain lengths have progressively higher boiling points, so they can be separated out by distillation. This is what happens in an oil refinery -- crude oil is heated and the different chains are pulled out by their vaporization temperatures. (See How Oil Refining Works for details.)

The chains in the C5, C6 and C7 range are all very light, easily vaporized, clear liquids called naphthas. They are used as solvents -- dry cleaning fluids can be made from these liquids, as well as paint solvents and other quick-drying products.

The chains from C7H16 through C11H24 are blended together and used for gasoline. All of them vaporize at temperatures below the boiling point of water. That's why if you spill gasoline on the ground it evaporates very quickly.

Next is kerosene, in the C12 to C15 range, followed by diesel fuel and heavier fuel oils (like heating oil for houses).

Next come the lubricating oils. These oils no longer vaporize in any way at normal temperatures. For example, engine oil can run all day at 250 degrees F (121 degrees C) without vaporizing at all. Oils go from very light (like 3-in-1 oil) through various thicknesses of motor oil through very thick gear oils and then semi-solid greases. Vasoline falls in there as well.

Chains above the C20 range form solids, starting with paraffin wax, then tar and finally asphaltic bitumen, which used to make asphalt roads.

All of these different substances come from crude oil. The only difference is the length of the carbon chains!

How Tidal Power Plants Work

The rise and fall of the sea

level can power electric-generating equipment. The gearing of the equipment is

tremendous to turn the very slow motion of the tide into enough displacement to

produce energy.

The rise and fall of the sea

level can power electric-generating equipment. The gearing of the equipment is

tremendous to turn the very slow motion of the tide into enough displacement to

produce energy.

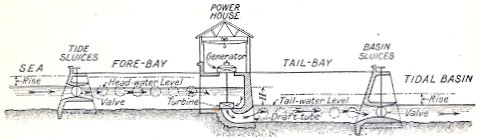

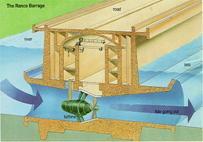

Tidal energy traditionally involves erecting a dam across the opening to a tidal basin. The dam includes a sluice that is opened to allow the tide to flow into the basin; the sluice is then closed, and as the sea level drops, traditional hydropower technologies can be used to generate electricity from the elevated water in the basin. Some researchers are also trying to extract energy directly from tidal flow streams.

The

energy potential of tidal basins is large the largest facility, the La Rance

station in

Tidal energy systems can have environmental impacts on tidal basins because of reduced tidal flow and silt buildup.

Using the Energy of the Ocean

There

are three basic ways to tap the ocean for its energy. We can use the ocean's

waves, we can use the ocean's high and low tides, or we can use temperature

differences in the water. Let's take a look at each.

Wave Energy

Kinetic

energy (movement) exists in the moving waves of the ocean. That energy can be

used to power a turbine. In this  simple example, to the right, the

wave rises into a chamber. The rising water forces the air out of the chamber.

The moving air spins a turbine which can turn a generator.

simple example, to the right, the

wave rises into a chamber. The rising water forces the air out of the chamber.

The moving air spins a turbine which can turn a generator.

When the wave goes down, air flows through the turbine and back into the chamber through doors that are normally closed.

This is only one type of wave-energy system. Others actually use the up and down motion of the wave to power a piston that moves up and down inside a cylinder. That piston can also turn a generator.

Most wave-energy systems are very small. But, they can be used to power a warning buoy or a small light house.

Tidal Energy

Another form of ocean energy is called tidal energy. When tides comes into the shore, they can be trapped in reservoirs behind dams. Then when the tide drops, the water behind the dam can be let out just like in a regular hydroelectric power plant.

In order

for this to work well, you need large increases in tides. An increase of at

least 16 feet between low tide to high tide is needed.

There are only a few places where this tide change occurs around the earth.

Some power plants are already operating using this idea. One plant in

Ocean Thermal Energy

The final ocean energy idea uses temperature differences in the ocean. If you ever went swimming in the ocean and dove deep below the surface, you would have noticed that the water gets colder the deeper you go. It's warmer on the surface because sunlight warms the water. But below the surface, the ocean gets very cold. That's why scuba divers wear wet suits when they dive down deep. Their wet suits trapped their body heat to keep them warm.

Power plants can be built that use this difference in temperature to make energy. A difference of at least 38 degrees Fahrenheit is needed between the warmer surface water and the colder deep ocean water.

Using

this type of energy source is called Ocean Thermal Energy Conversion or OTEC.

It is being used in both

Tidal

and Wave Power

Tidal power operates by building a barrier across a river estuary. The tidal

flow drives turbines to produce electricity.

Today,

solar power and lunar power.

The

Renewable energy is a term worth looking at.

We can use direct solar energy to heat water or our homes. We can focus solar

energy to supply steam boilers. We can build engines to take energy from the

warm surface of the ocean and discharge it into the cold water below. We use

solar cells to convert solar energy to electricity. Nature often does the work

of converting heat into usable power for us, by moving water and wind

around the planet. Thus windmills and hydroelectric plants deliver solar power.

Renewable energy is a term worth looking at.

We can use direct solar energy to heat water or our homes. We can focus solar

energy to supply steam boilers. We can build engines to take energy from the

warm surface of the ocean and discharge it into the cold water below. We use

solar cells to convert solar energy to electricity. Nature often does the work

of converting heat into usable power for us, by moving water and wind

around the planet. Thus windmills and hydroelectric plants deliver solar power.

We call such energy renewable only because the sun replaces what we use. No energy is truly renewable. Sooner or later, every source runs down, even the sun. It's just in comparison with our brief human lives, that it might as well be inexhaustible.

Another nearly

inexhaustible source of energy is planetary kinetic energy. Every

day the moon's gravitational pull lifts countless tons of water up into, say,

the East River or the

So where did that energy come from? It was taken from the moon's and Earth's kinetic energy. The tides slow us down. Each year on Earth is about half-a-second longer than the one before it. But, like the flow of solar energy, that consumption is present whether we claim it or not.

We might claim it in many ways. The most obvious is to catch sea water at high tide, then run it out through a turbine during low tide.

Still, every large energy system comes at a price. Fossil fuels soil the air. The problem of nuclear waste haunts us. Hydroelectric dams create huge reservoirs and pose a threat when they grow old. Modern windmills kill endangered birds as well as consuming real estate. So what price do we pay for tidal power?

It has the potential for picking up about a fiftieth of our energy consumption. That could be a great help, but never more than a help. Tidal power systems are potentially big and expen-sive, and they pose poorly understood threats to ocean ecosystems.

Tidal power (what I like to call lunar energy) is not new. Tidal mills were built in the eighteenth century when their major competition were windmills and water wheels. The tidal mills largely vanished once we had cheap steam engines.

I have a 1921 book on Tidal Power that describes systems we might use today. It discusses tidal variability and intermittency and treats the delicate business of placing tidal plants.

Power use in 1921 was only a thirtieth of today's consumption. Even then, tidal power clearly couldn't have been enough to replace the use of coal. Yet tidal power was going to waste then, as it goes to waste today. The author of this old book might as well be writing for us when he sums up the situation by quoting Cecil Rhodes' dying sigh, 'So little done, so much to do.'

Moduri de folosire a apei

Energy From Water

Energy From Water

Welcome to my third web page on renewable energy sources! In the few minutes it will take you to read this page, you will be covering: 75% of our planet's surface, the substance in your drinking glass, and the element from which you are mostly made. I hope it doesn't take you too long to figure out that this substance is water. Our planet's water supply has transformed a barren planet into the green and blue object astronauts have spent hours staring at in awe. Water has provided for our needs in many ways, and may easily do it again. This time water is providing the electricity that our modern-day society greatly depends on.

The first question is, 'How can we use water to create

electricity?' There are four main ways in which we use water to

create electricity. The first way is by harnessing the power of moving

water in large rivers. By building a dam in a selected area, you can

create a large reservoir of water with a great deal of pressure. Holes in

the side of the dam lead to turbines, which spin as a controlled amount of

water exits the dam.

The second way we use water to create electricity is by the changing of

tides. Tidal power plants are producing electricity for their nearby

consumers in

The third way we can

create hydroelectricity is by harnessing the power of waves. Large

flotation devices can be placed in an area noted for regular wave action.

These flotation devices are attached to a crankshaft underneath the water's

surface. As the flotation devices move up and down, they cause the

crankshaft to spin. This crankshaft is attached to a generator which

produces electricity. Although there are many inventions which also use

the power of waves, this method tends to be the most popular.

The third way we can

create hydroelectricity is by harnessing the power of waves. Large

flotation devices can be placed in an area noted for regular wave action.

These flotation devices are attached to a crankshaft underneath the water's

surface. As the flotation devices move up and down, they cause the

crankshaft to spin. This crankshaft is attached to a generator which

produces electricity. Although there are many inventions which also use

the power of waves, this method tends to be the most popular.