| CATEGORII DOCUMENTE |

| Bulgara | Ceha slovaca | Croata | Engleza | Estona | Finlandeza | Franceza |

| Germana | Italiana | Letona | Lituaniana | Maghiara | Olandeza | Poloneza |

| Sarba | Slovena | Spaniola | Suedeza | Turca | Ucraineana |

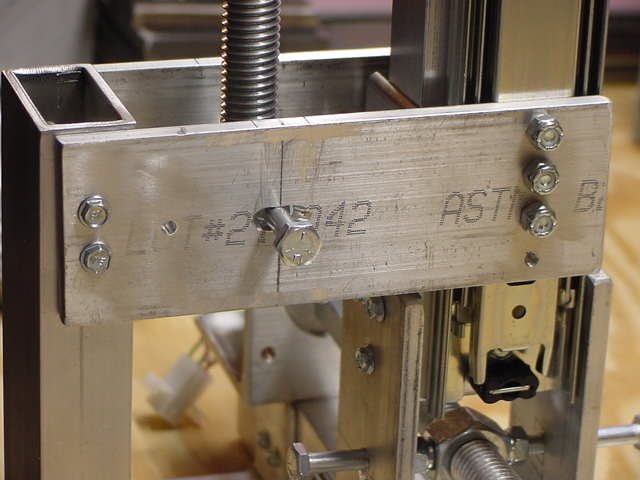

Y Axis

Here I am building the two Y posts. The

posts can be found at the fence section at Home

Depot

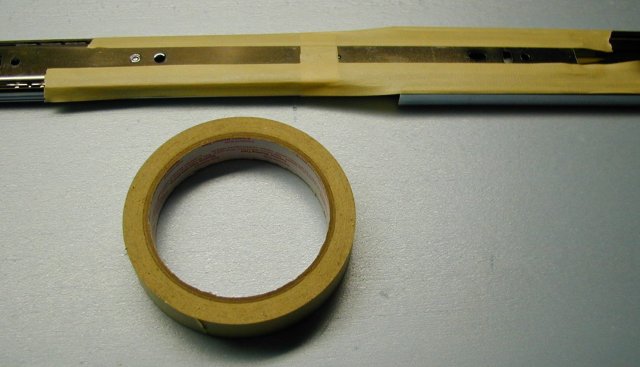

Got

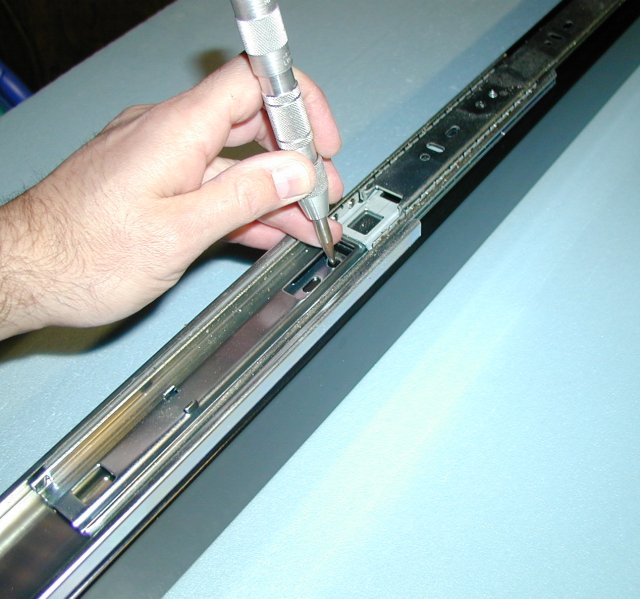

two 16' drawer slides

Here is the Home Depot Catalog number for 24'

slides made by

7-81266-18070-4

And two 4 foot stands

The above picture is of the 2'x4FT Post with foot - that's the Home Depot

name

Cat num: 204-008

Home Depot num: 6-39426-48607-7

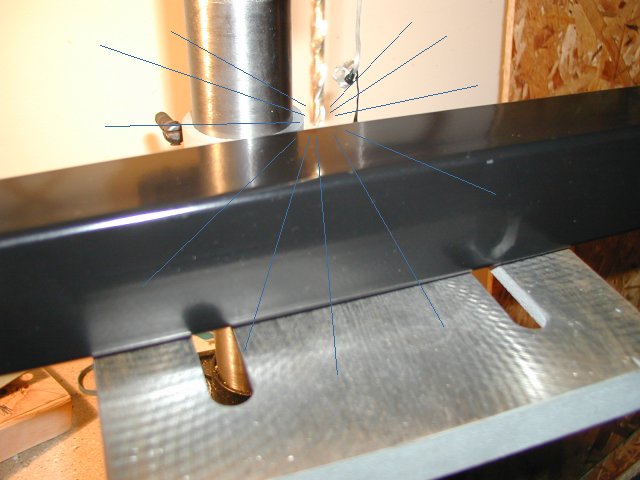

6' from the base

Mark both holes

Now the 2nd one

Drill the two holes

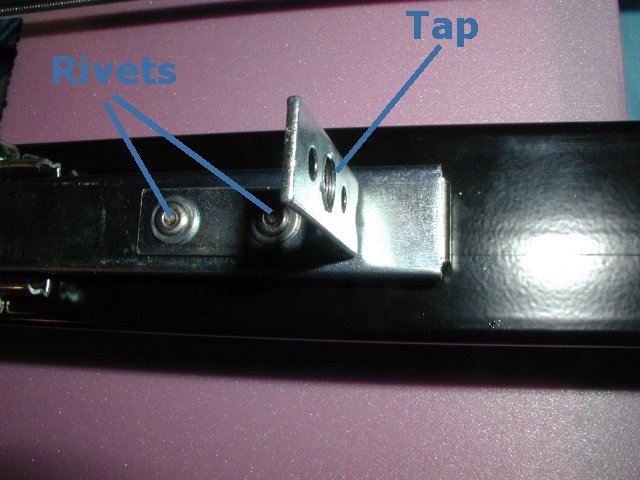

Place the rivets

Use the River gun - make sure that no dirt will reach the bearings !!!

And now do the same for the other stand

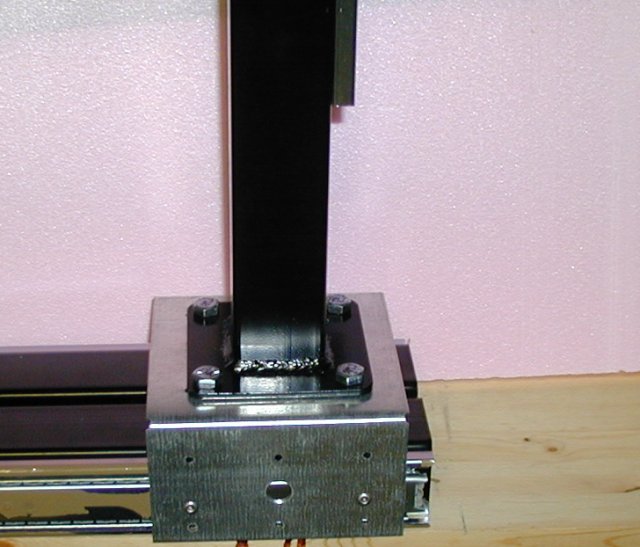

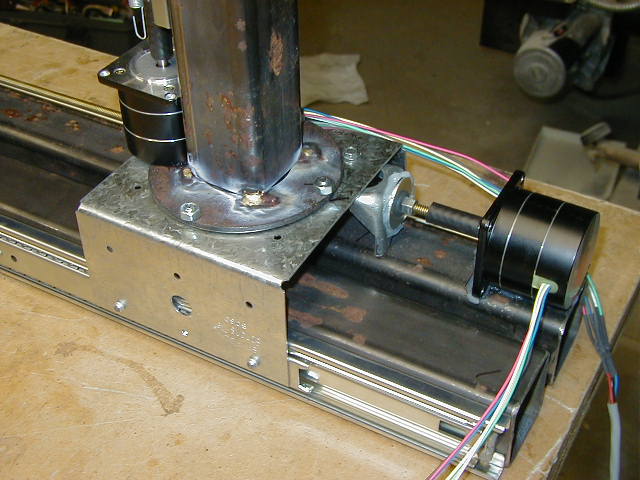

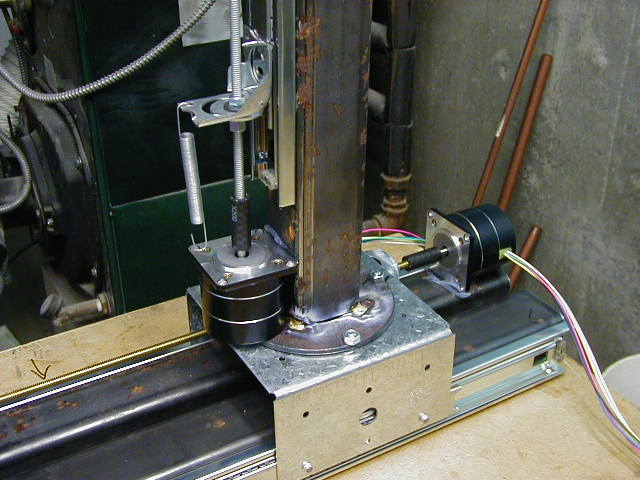

X

Axis

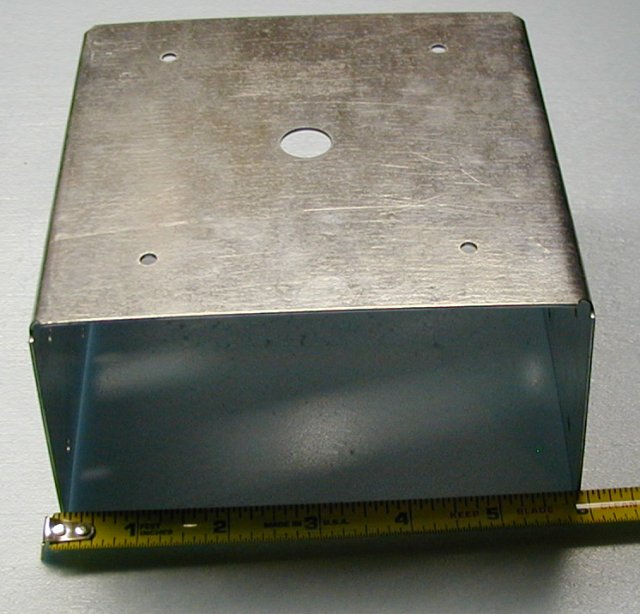

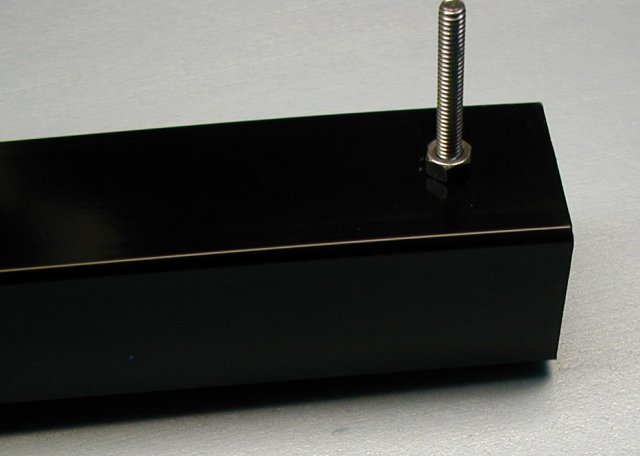

This will hold the Y axis stud.

Here is the Home Depot Catalog number for the part below:

'Half Base' made by Company named Simpson

Catalog number : C751-973

Home Depot num: 044315-10350

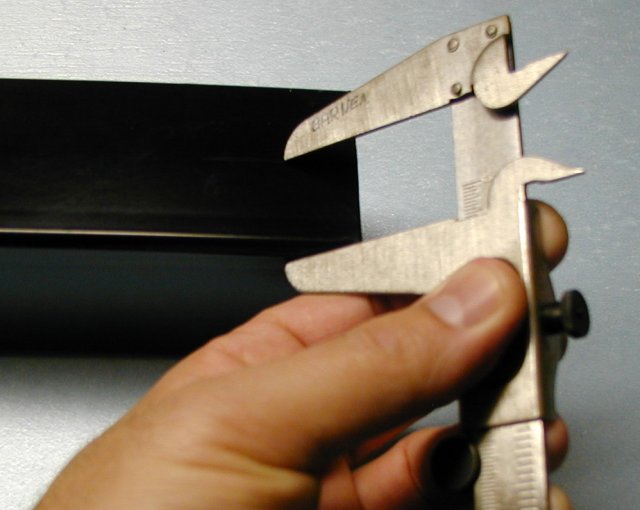

Now drill the 3 holes on the slides (24' slides)

Put something on the slides so no dirt will reach the bearings - This is very important !!!!!

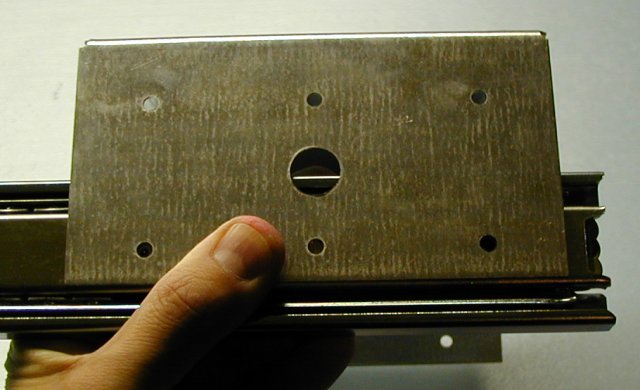

Mark the 4 holes for the Y axis

2x25' studs, measure 1' from the edge and 1' from the side and drill the holes

Place 2 screws - these screws will hold the two studs together.

Connect the slides to the studs (take a look at Day 1 for more info)

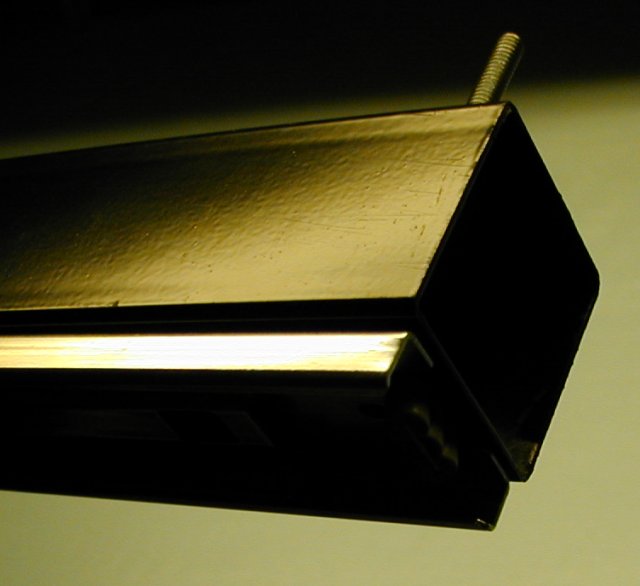

A closer look

And another one

The two studs connected together (at the bottom you can see the slide)

Connect the top part to the slides

Another look

And you are done

Now make another unit just like it - there are two of these in each machine.

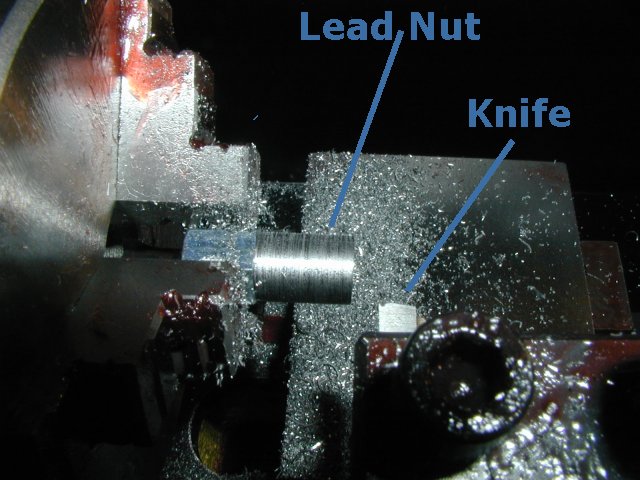

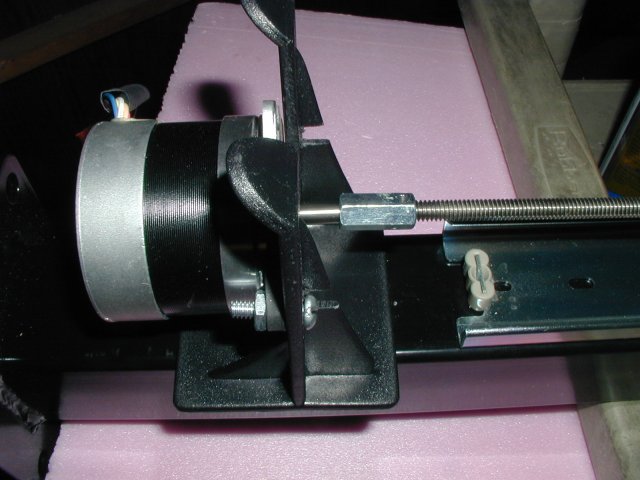

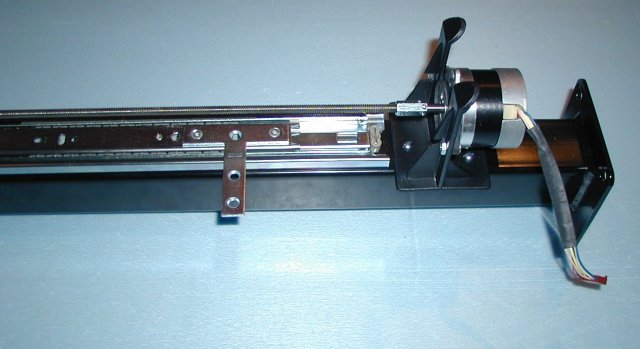

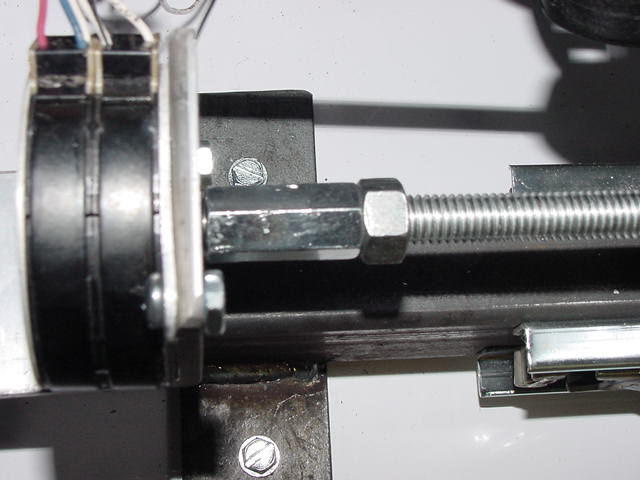

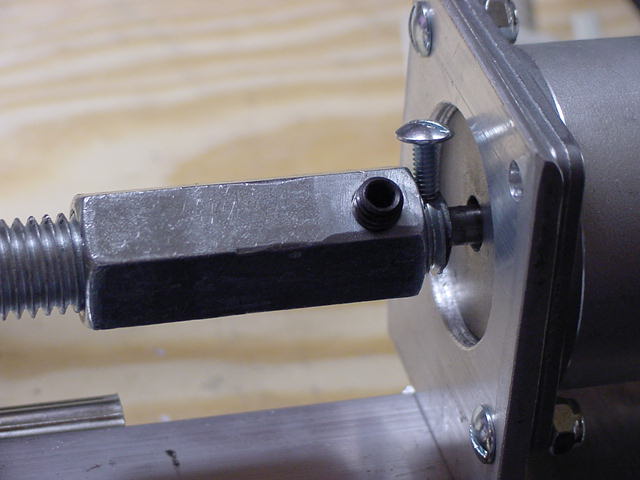

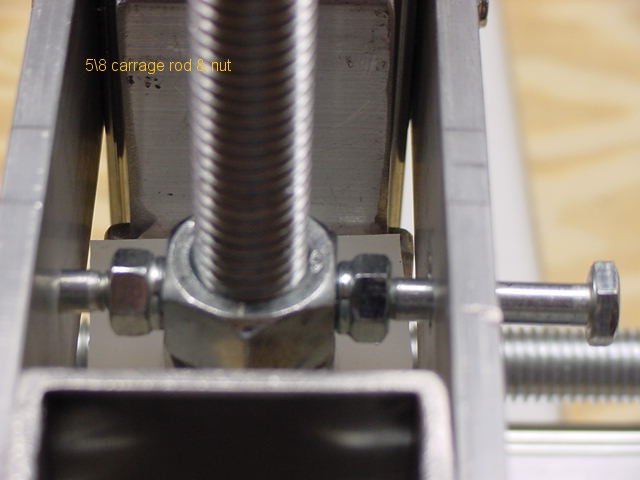

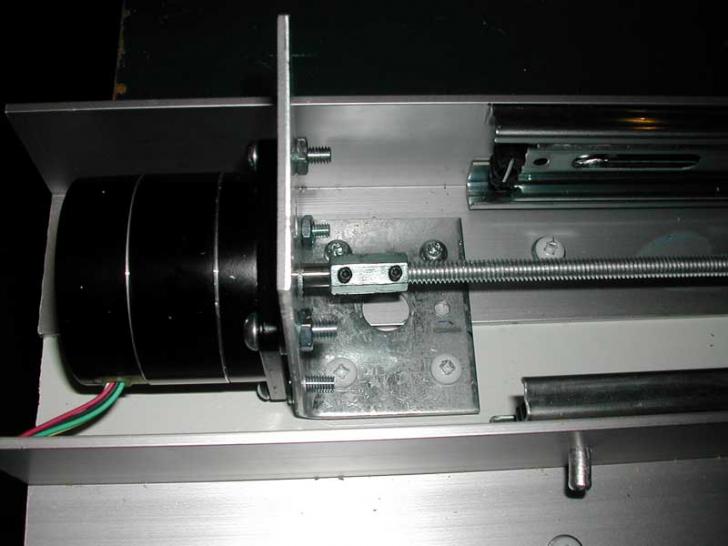

Lead Screw and the Lead nut

For this section, I used a lathe and a set of tap and die.

There might be ways around, but I chose to go the safe route.

Lead Screw : Stainless Steel preferred

Threaded rod USS/Course Stainless steel

1/4' x 20 x 36'

Home Depot catalog number : 0 30699 48000 5

Lead

nut:

1/4' x 7/8' Home Depot Catalog number: 0 30699

19116 1

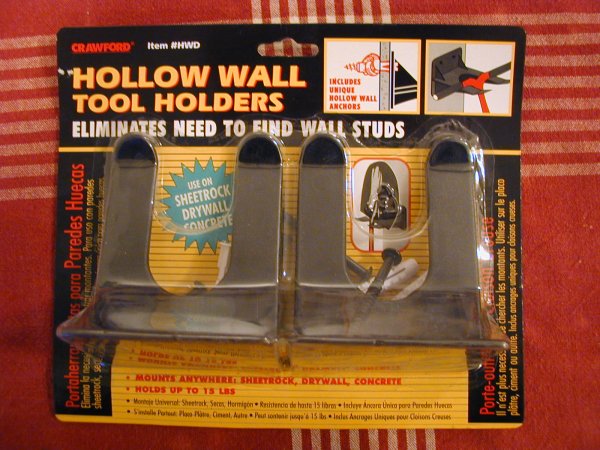

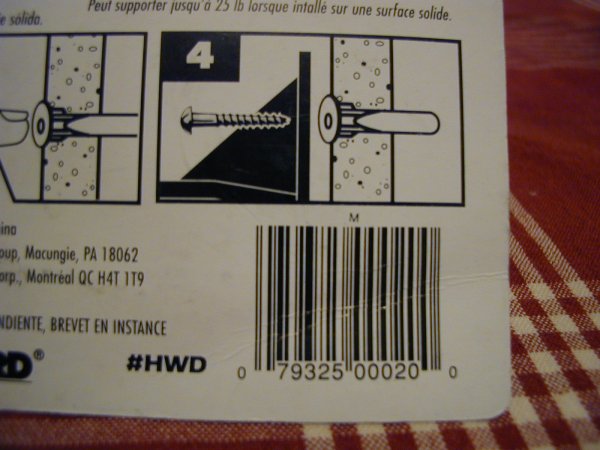

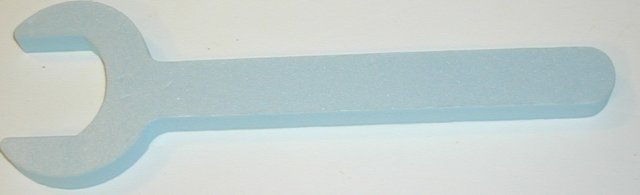

Here is what I used for a motor mount:

Barcode

Made out of plastic - easy to saw, drill and strong enough for any NEMA 23 motor

Why

use plastic ? Plastic is forgiving, if for any reason

the motor shaft and the lead screw are

not perfectly aligned, the plastic mount will bend a bit and the wobble will

not be

noticeable on the cut

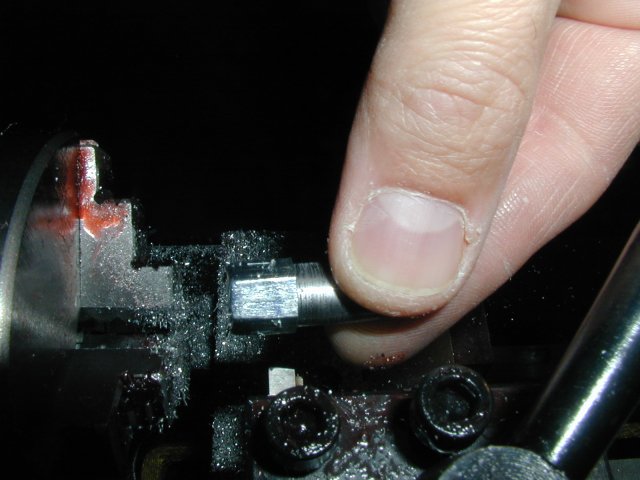

No explanation needed

Another look

And another one

Use rivets to hold the lead nut in place

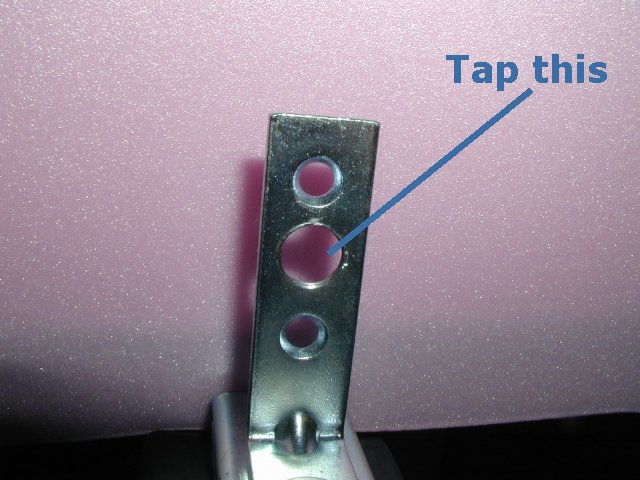

Top end

The top end

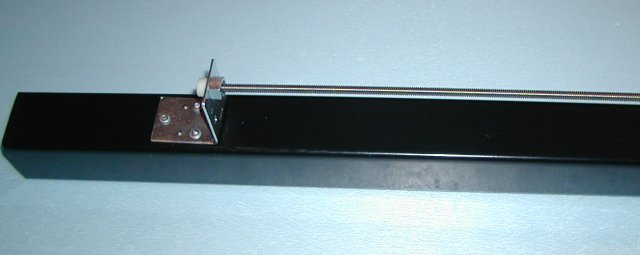

So

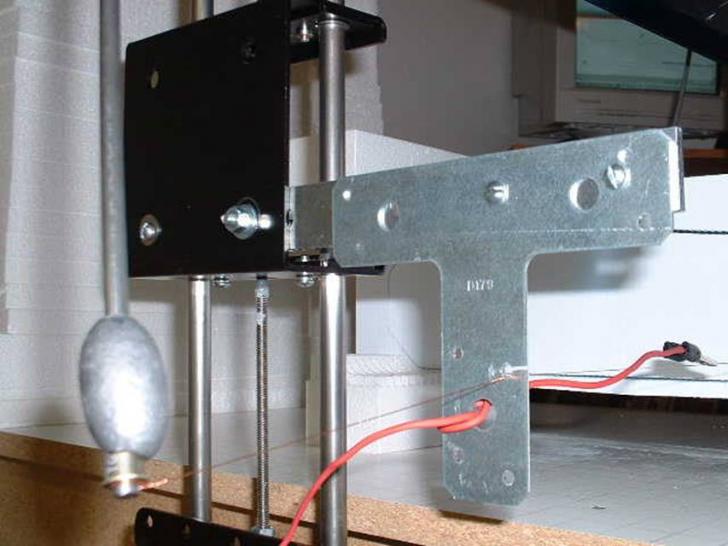

this is how it should look !!!!

Now, make another one just like it, but mirrored.

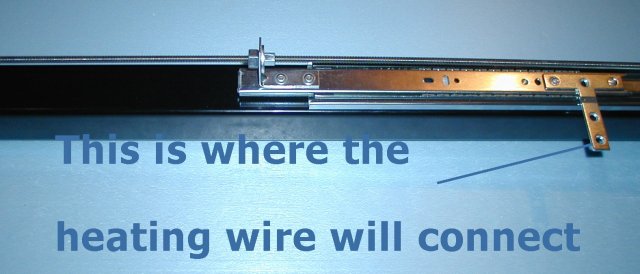

The last picture on this page shows that the two 'T' brackets are

facing each other

This is where the hot wire will connect. For those who wish to mass produce

wings

simply add one or even two more 'T' brackets and you can cut 3 cores

at a time.

Thanks for the correction Steve :)

Click here for our online store - CNC parts

Now lets put it all together

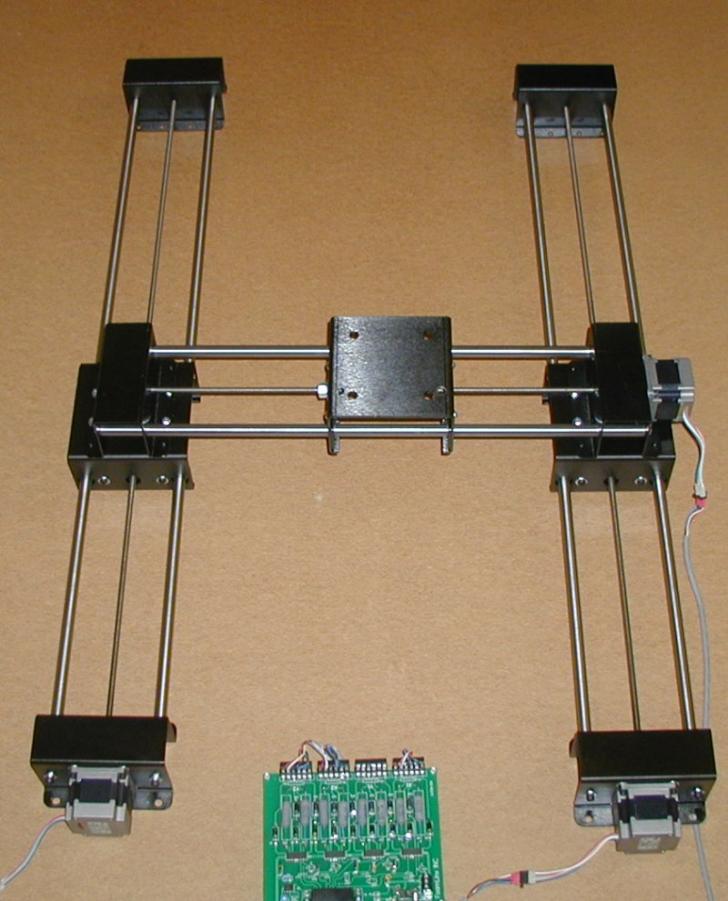

The

electronics

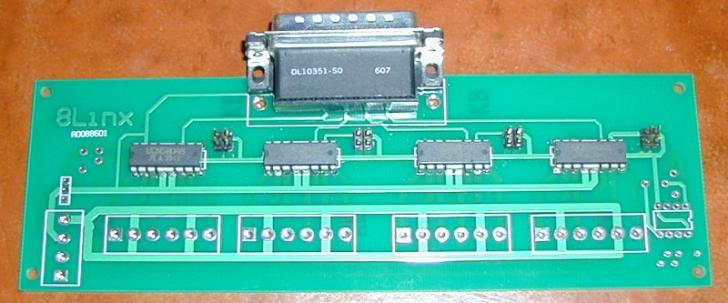

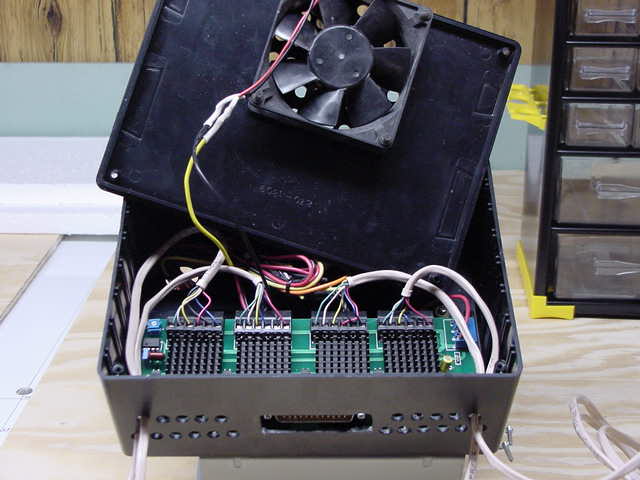

PCB (Printer Circuit Board) design and assembly

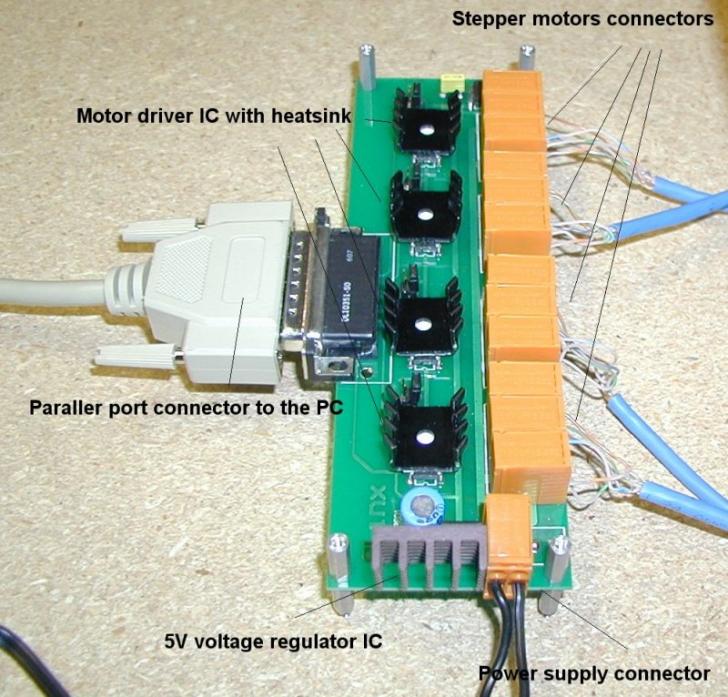

Component side with printer cable connector and stepper motor drivers soldered,

the 4 four pin connectors on the top right side of each stepper motor IC are

full step/half step. In order to operate the board in half step mode,

connect jumpers on the top two pins.

A larger picture for more detail. You will also need a

simple Parallel port cable - just make sure its pin to pin cable

The cable - D25 male to D24 female pin to pin connection

We no longer sell the

boards and motors.

You can find controllers and motors at HobbyCNC.com

Motors

are 5V or 6V or 12V Unipolar

stepper motor rated at about 1A, they can be found at most surplus stores

Here is where I got mine: https://www.allelectronics.com.

At the moment they are not available but check from time to

time for availability. Make sure that if you use a 6V motor - then use a

6V power supply.

Same with 12V motor - use a 12V power supply (PC power supply will work great

for a 12V motors)

Below is a 6V stepper motor that I use on the machine.

The stepper motor drivers are Unipolar stepper

motor drivers which means the motor has two main coils

with a center tap for each coil, in other words stepper motors which have 6

wires.

Here is a link to the most popular drivers from Allegro Micro - https://www.allegromicro.com/datafile/5804.pdf

The stepper motor ICs must get 5VDC, and if you

plan to use motors that are not 5V, you will have to

use a 5V voltage regulator shown with a heat sink on the large picture.

A simple 7805 can be used for that. Can be found in any

electronics store.

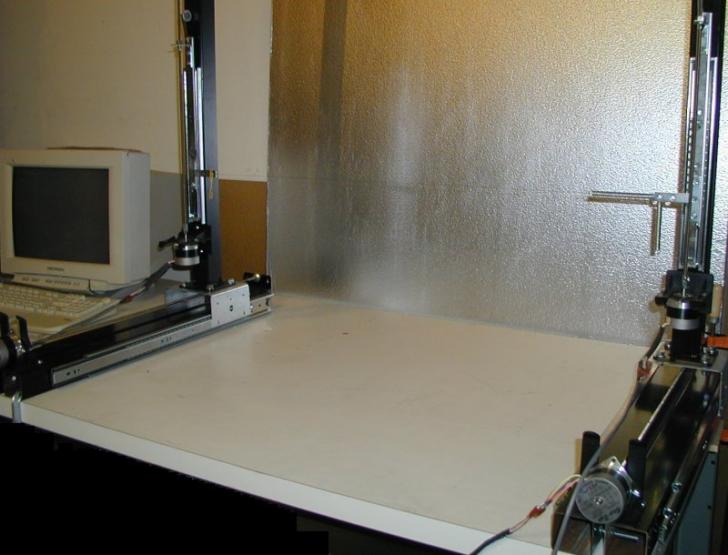

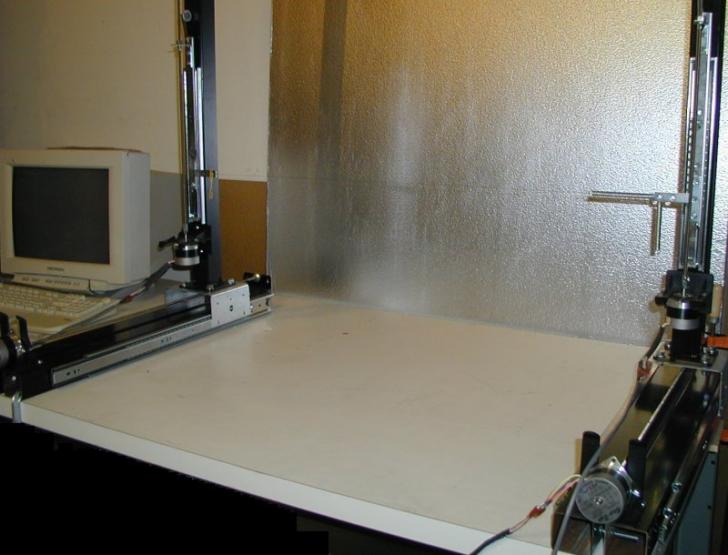

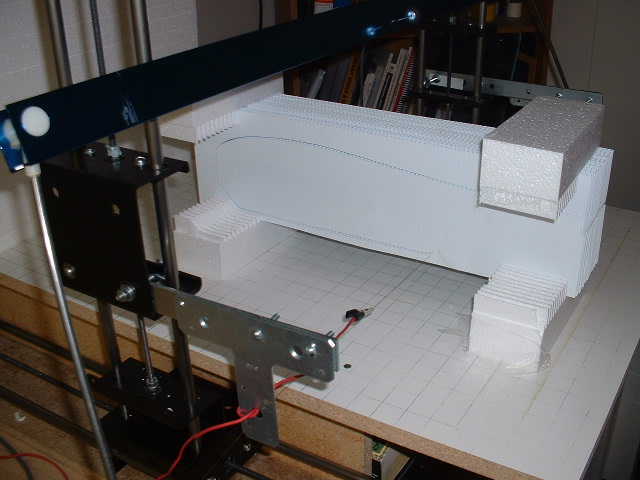

Putting it all together

Put it all together and test it

Table all ready to go. Clamp down both axis, one shown

on the bottom left side.

I use strong spring to keep the cutting wire tight. The spring also keeps the

wire tight when cutting a tapered wing.

You can get the spring in your local Home Depot. On some designs I have seen

people using a bow instead of the

spring design. I got better results with the spring, but feel free to

experiment

Here is a setup which I also use on my foam cutting

bow. The router speed control can handle up to 15A

And the power supply can supply up to 3.5A which is

more then enough current for a 30' wire. (about

1.5A)

The low voltage power supply is used to isolate the main voltage (110V) from

the cutting wire.

The

software I use is: https://gm.cnc.free.fr/index_en.html

This software is the most popular foam cutting controller software, and

also not to expensive (about $32)

It will control up to 4 motors and let you cut tapered wings and other shapes,

take a close look at the site

There is a lot of useful information there, and even a link where people who

built foam cutting CNCs post

their pictures.

Here is a

link to a large number of foils

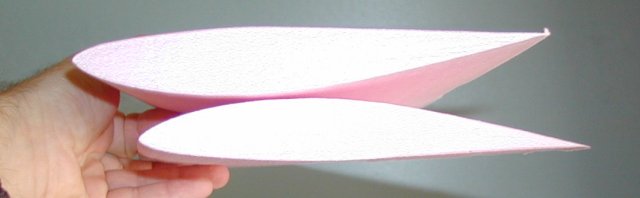

Some

Sample cuts

Questions, recommendations please contact me at

foam@8linx.com

Machine built by Vern

A great idea how to alien the lead screw and the motor shaft

Nice cut !!

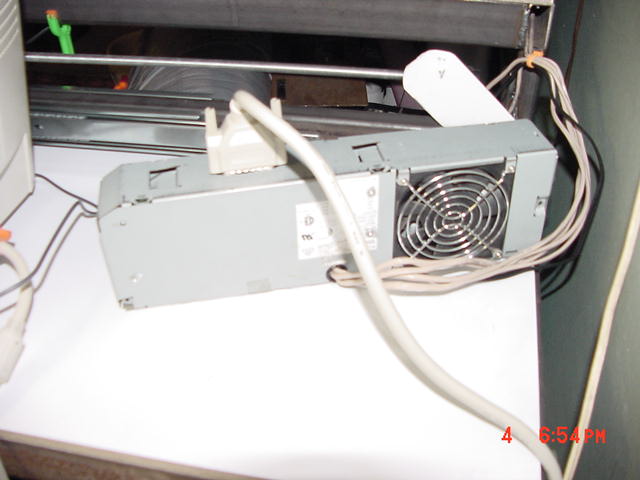

Stepper motor driver board with a fan

Some

more great ideas from Vern

Machine

built by Rick Hallett happl@midmaine.com

Cutter made by Ron Kruse

Some picture from people who purchased our new machines

A

picture from Glenn Corrie

A

machine in

Some very nice improvements done on our machines (thanks !!!)

Machine that Andrew Donatelli built

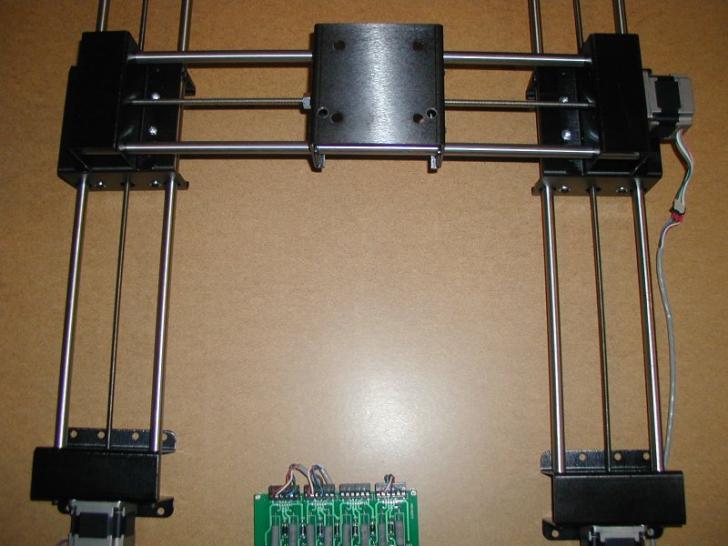

Here

is an XY plotter/cutter based on the linear slides used in the foam cutter

In the future we plan to

Notice the new stepper motor driver which can support up to 4 unipolar motors.

It is designed to work with most CNC software. The one shown above is from www.kellyware.com

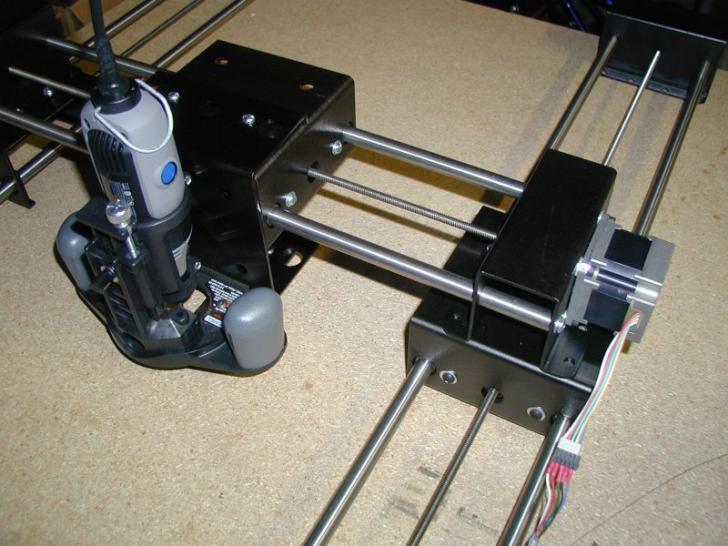

Same

table with a Dremil mounted - Notice that the Dremil Z movement is not controlled by the PC (at the

moment)

|

Politica de confidentialitate | Termeni si conditii de utilizare |

Vizualizari: 6326

Importanta: ![]()

Termeni si conditii de utilizare | Contact

© SCRIGROUP 2025 . All rights reserved