| CATEGORII DOCUMENTE |

| Bulgara | Ceha slovaca | Croata | Engleza | Estona | Finlandeza | Franceza |

| Germana | Italiana | Letona | Lituaniana | Maghiara | Olandeza | Poloneza |

| Sarba | Slovena | Spaniola | Suedeza | Turca | Ucraineana |

1 Theoretical Background

1.1 Basic Theory of Axial Deformation

Definition 1

A plane linear member, when subjected to exterior loads and/or change of temperature, undergoes an axial deformation if after the deformation:

(a) the axis of the member remains straight;

(b) the cross-sections remain plane, perpendicular to the longitudinal axis of the beam and do not rotate about the same longitudinal axis after the deformation.

Equilibrium Equation

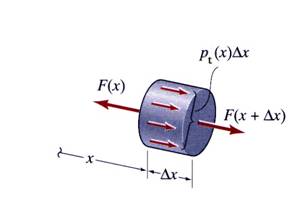

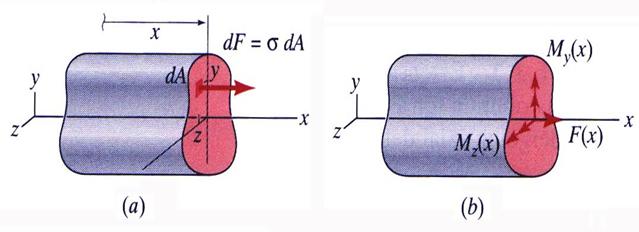

Figure 1 Equilibrium of an Elementary Beam Volume

The differential relation between the exterior load and the axial internal resultant is obtained from the equilibrium of the elementary volume:

![]() (1)

(1)

where ![]() is the distributed

loading parallel to the beam longitudinal axis and

is the distributed

loading parallel to the beam longitudinal axis and ![]() is the axial stress

resultant .

is the axial stress

resultant .

Integrating equation (1) the stress resultant force ![]() in a particular

cross-section is calculated as:

in a particular

cross-section is calculated as:

![]() (2)

(2)

where ![]() is the value of the axial force at the origin of the

integration interval.

is the value of the axial force at the origin of the

integration interval.

Strain-Displacement Equation

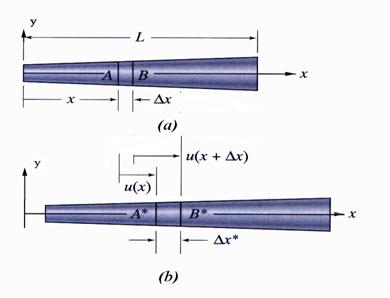

Figure 1 Geometrical Aspects of the Axial Deformation

(a) Undeformed Member and (b) Deformed Member

The extensional

strain ![]() along the longitudinal

axis of the beam is obtained using the notation shown in Figure 1:

along the longitudinal

axis of the beam is obtained using the notation shown in Figure 1:

![]() (3)

(3)

The rest of the generalized strain tensor components, extensional and shear strains, are:

![]() (4)

(4)

![]() (5)

(5)

![]() (6)

(6)

The expression of the generalized strain tensor ![]() is:

is:

(7)

(7)

The displacement ![]() is obtained by integration the differential equation (3):

is obtained by integration the differential equation (3):

![]() (8)

(8)

where ![]() is the displacement at the beginning at the integration

interval.

is the displacement at the beginning at the integration

interval.

The elongation is calculated using equation (8) as:

![]() (9)

(9)

where ![]() is the total length of the bar.

is the total length of the bar.

Constitutive Equation

The constitutive equation reflects the relation between the

stress and the strain. If the linear elastic

material behavior is considered, applying the Hooks Law, the relation

between the normal stress ![]() and extension strain

and extension strain ![]() is written:

is written:

![]() (10)

(10)

where![]() is the modulus of elasticity and is obtained performing

tensile tests.

is the modulus of elasticity and is obtained performing

tensile tests.

Considering the assumption that the cross-section of the bar

is a small surface, the variation of the modulus of elasticity ![]() is negligible on this surface, and consequently, the

constitutive equation (10) is expressed as:

is negligible on this surface, and consequently, the

constitutive equation (10) is expressed as:

![]() (11)

(11)

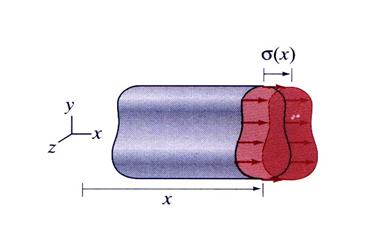

Note: equation (11) implies that the normal stress ![]() varies only along the

length of the member, but has a constant value on the entire cross-section.

varies only along the

length of the member, but has a constant value on the entire cross-section.

The representation of the normal stress ![]() is shown in Figure 2.

is shown in Figure 2.

Figure 2 Cross-Section

Note: equation (11) implies that the normal stress ![]() varies only along the

length of the member, but has a constant value on the entire cross-section.

varies only along the

length of the member, but has a constant value on the entire cross-section.

The rest of the stress tensor ![]() components are zero:

components are zero:

![]() (12)

(12)

![]() (13)

(13)

Consequently, the generalized stress tensor is:

(14)

(14)

Cross-Section Stress (Internal) Resultants

The following cross-sectional stress (internal) resultants are obtained using the stress distribution expressed by equation (11) through (13):

![]() (15)

(15)

![]() (16)

(16)

![]() (17)

(17)

The relations between the normal stress ![]() and the cross-section

resultants

and the cross-section

resultants![]() ,

, ![]() and

and ![]() are derived using the

notation shown in Figure 3.

are derived using the

notation shown in Figure 3.

Figure 3

(a) Normal Stress and (b) Stress Resultants

If the axes ![]() and

and ![]() of the coordinate system intersect such that the

of the coordinate system intersect such that the ![]() axis passes through the cross-section centroid, the static

moments

axis passes through the cross-section centroid, the static

moments ![]() and

and ![]() are zero and the axial

force

are zero and the axial

force![]() remains the only non-zero stress resultant:

remains the only non-zero stress resultant:

![]() (18)

(18)

![]() (19)

(19)

![]() (20)

(20)

Then, from equation (18) the normal stress![]() is calculated as:

is calculated as:

![]() (21)

(21)

Note: It is concluded that a beam made from a linear elastic material undergoes an axial deformation if the axial force passes through the cross-section centroid.

Thermal Effects on Axial Deformation

The thermal strain was introduced as:

![]() (22)

(22)

where ![]() is the thermal

expansion coefficient and

is the thermal

expansion coefficient and ![]() is the change in the

member temperature.

is the change in the

member temperature.

The total elongation strain is the sum of the elongation strain induced by the exterior load action and thermal effects and is expressed as:

![]() (23)

(23)

Then, the total elongation of the member is written as:

![]() (24)

(24)

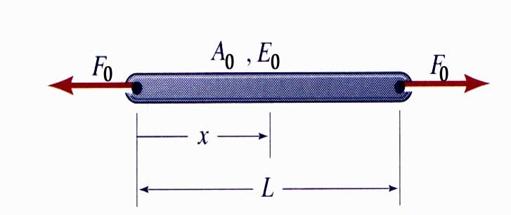

Uniform-Axial Deformation

Definition 2

The uniform axial-deformation element is a linear member characterized by:

(a) a constant area along the entire length of the member;

(b) is made of a homogeneous elastic material;

(c)

is subjected to a constant axial force ![]()

Uniform-axial deformed members (shown in Figure 4)

.

Figure 4 Member Exhibiting Uniform Axial-Deformation

Transcribing the requirements of the definition 2 the following expressions are obtained:

![]() (25)

(25)

![]() (26)

(26)

![]() (27)

(27)

Note: Equation

(27) implies the absence of the distributed load![]() .

.

Rewriting equations (21), (23) and (24) previously obtained for the case of the member with uniform axial-deformation the following equations are obtained:

![]() for axial stress (28)

for axial stress (28)

![]() for elongation strain (29)

for elongation strain (29)

for total elongation (30)

for total elongation (30)

Axial flexibility and stiffness coefficients

![]() the axial

stiffness coefficient. (31)

the axial

stiffness coefficient. (31)

![]() axial

flexibility coefficient (32)

axial

flexibility coefficient (32)

Substituting the equation (32) into the total elongation expression (30), the total elongation of a bar under uniform-axial deformation is recast as:

![]() (33)

(33)

Nonuniform-Axial Deformation

If any one of the assumptions contained in definition 2 is violated the axial deformation is called nonuniform-axial deformation. The most common cases of nonuniform-axial deformation are:

Member with non-homogeneous cross-section;

Member with variable Cross-Section;

Member loaded along its length.

The formulae described in the section 1.1 have to be adapted function of the situation.

Verification of the Members Subjected to Axial Deformation

The design formula used is the relationship between maximum

normal stress ![]() and the allowable

normal stress

and the allowable

normal stress![]() :

:

![]() (34)

(34)

The formula (34) was used for a long period of time in a

procedure known as the allowable-stress

design. Due to the simplicity of application, this method is still commonly

used in

The allowable normal stress ![]() is defined by limiting

the value of the normal stress in the axially deformed member. Dividing the

yield stress

is defined by limiting

the value of the normal stress in the axially deformed member. Dividing the

yield stress ![]() pertinent to the material subjected to axial deformation by a

safety factor

pertinent to the material subjected to axial deformation by a

safety factor![]() the allowable axial stress is calculated:

the allowable axial stress is calculated:

![]() (35)

(35)

The safety factor is greater than one, usually taking values between 2 and 3. The yield stress for different materials is found in Appendix 1.2.

2 Solved Problems

Problem 2.1

A solid brass rod AB and a solid aluminum rod BC are

connected together by a rigid coupler of negligible length at B as shown in

Figure 2.1.a. The diameters and the modulus of elasticity of the two segments

are d1 = 65 mm, d2 = 50 mm, E1 = 105 GPa and E1

= 69 GPa, respectively. The system is loaded by two concentrated loads, ![]() and

and ![]() , acting along the

centroidal line of the system at point

, acting along the

centroidal line of the system at point ![]() and

and ![]() , respectively . Calculate the axial stress existing in the

two rods and the displacement at point B and C. Verify the rod segments.

, respectively . Calculate the axial stress existing in the

two rods and the displacement at point B and C. Verify the rod segments.

Figure 2.1.a

A. General Observations

Two axial forces are acting on the rod:

![]() and

and ![]()

The areas of the two rod segments are:

![]()

![]()

![]()

![]()

B. Calculations

B.1 Free-Body Diagram

The constraint located at point A is

replaced by a horizontal reaction ![]() as shown in Figure 2.1.b.

as shown in Figure 2.1.b.

Figure 2.1.b

B.2 Reaction Calculation

The equation of equilibrium used is the projection of all

axial forces on the horizontal axis![]() :

:

![]()

![]()

![]()

The equilibrium equation contains only one unknown reaction

force,![]() , and consequently, the system is statically determinate.

, and consequently, the system is statically determinate.

B.3 The Axial Force Diagram

The axial force diagram is drawn in Figure 2.1.c.

Figure 2.1.c

The axial force on the interval ![]() is a constant tension force

is a constant tension force![]() ,

while on the interval

,

while on the interval ![]() is a constant

compression force

is a constant

compression force ![]() .

It can be concluded that both segments of the rod are uniform-axial deformed members.

.

It can be concluded that both segments of the rod are uniform-axial deformed members.

B.3 Stress and Strain Calculation

The stress and strain in the interval![]() , where the rod is made of solid brass are obtained as:

, where the rod is made of solid brass are obtained as:

![]()

![]()

![]() tension

stress

tension

stress

![]()

![]() elongation strain

elongation strain

In a similar manner is calculated the stress and strain

pertinent to the interval ![]() representing the

aluminum made rod.

representing the

aluminum made rod.

![]()

![]()

![]() compression stress

compression stress

![]()

![]() elongation strain

elongation strain

B.4 Flexibility Coefficients

The flexibility coefficients are calculated as:

![]()

![]()

![]()

![]()

![]()

![]()

B.5 Calculation of the axial displacements

The displacement ![]() of the point

of the point![]() , the right end of the brass segment, is calculated as:

, the right end of the brass segment, is calculated as:

![]()

![]()

![]()

where the displacement at the origin of the interval ![]() and

and![]() ,

because the point is constraint against the horizontal movement.

,

because the point is constraint against the horizontal movement.

The calculation of the displacement ![]() implies the knowledge of the displacement of the origin point

of the interval

implies the knowledge of the displacement of the origin point

of the interval![]() .

.

![]()

![]()

The displacement in point ![]() is calculated as:

is calculated as:

![]()

![]()

![]()

B.6 Verification of the Rod

The verification of the rod segments is conducted as:

for the brass segment

![]()

![]() ok

ok

where ![]() is the brass allowable

stress,

is the brass allowable

stress, ![]() is the brass yield

stress which can be found in Appendix 1.2, and

is the brass yield

stress which can be found in Appendix 1.2, and ![]() is the safety factor .

For this calculation

is the safety factor .

For this calculation ![]() and

and ![]() .

.

for the aluminum segment

![]()

![]() ok

ok

where ![]() is the brass allowable

stress,

is the brass allowable

stress, ![]() is the aluminum yield

stress which can be found in Appendix 1.2, and

is the aluminum yield

stress which can be found in Appendix 1.2, and ![]() is the safety factor . For this calculation

is the safety factor . For this calculation ![]() and

and![]() .

.

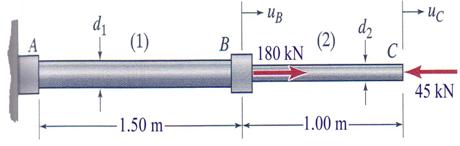

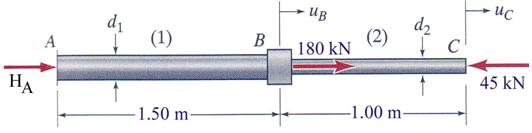

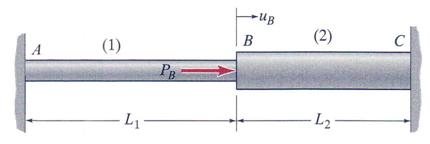

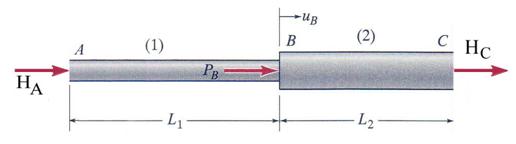

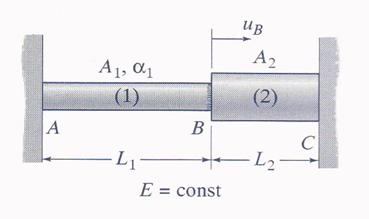

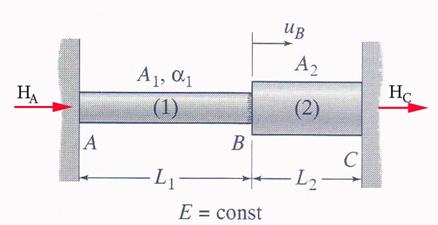

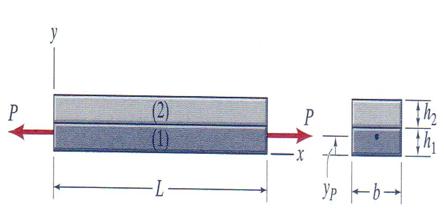

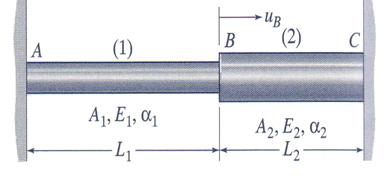

Problem 2.2

Two uniform, linearly elastic members are held together at point

B and the resulting two-segment rod is attached to rigid supports at ends A and

C. A single external load P = 4000 kN is applied at joint B. Member (1) has a

length ![]() m, diameter d1 = 120 mm and is made of steel with

a modulus of elasticity

m, diameter d1 = 120 mm and is made of steel with

a modulus of elasticity ![]() = 200 GPa. Member (2) has a length

= 200 GPa. Member (2) has a length ![]() = 1.8 m, diameter d2 = 150 mm and is made of an aluminum

alloy with a modulus of elasticity

= 1.8 m, diameter d2 = 150 mm and is made of an aluminum

alloy with a modulus of elasticity ![]() =75 GPa. Conduct the following tasks: (a) verify the axial

stress in both members and (b) calculate the axial displacement at point B.

=75 GPa. Conduct the following tasks: (a) verify the axial

stress in both members and (b) calculate the axial displacement at point B.

Figure 2.2.a

A. General Observations

The areas of the two rod segments are:

![]()

![]()

B. Calculations

B.1 Free-Body Diagram

The constraint located at point A is

replaced by a horizontal reaction ![]() as shown in Figure 2.2.b.

as shown in Figure 2.2.b.

Figure 2.2.b

B.2 Reaction Calculation

The equation of equilibrium used is the projection of all

axial forces on the horizontal axis![]() :

:

![]()

The equation contains

two (2) unknown reaction forces ![]() and

and![]() . Consequently,

the system is a statically indeterminate. An additional equation is necessary. This is equation is geometrical in

nature and represents the fact that the total elongation of the beam is zero.

. Consequently,

the system is a statically indeterminate. An additional equation is necessary. This is equation is geometrical in

nature and represents the fact that the total elongation of the beam is zero.

![]()

Considering that the calculation of the displacement starts

at point A, ![]() and the axial displacement at

the end B of the interval

and the axial displacement at

the end B of the interval![]() , representing the steel rod, is calculated as:

, representing the steel rod, is calculated as:

At the left end of the ![]() interval the axial displacement is expressed as:

interval the axial displacement is expressed as:

This way the second equation is obtained as:

![]()

and by substituting the flexibility coefficients ![]() and

and ![]() into the

expression of the axial displacement

into the

expression of the axial displacement ![]() the following algebraic system is obtained:

the following algebraic system is obtained:

![]()

![]()

The solutions, representing the two reactions, ![]() and

and ![]() , are found:

, are found:

Substituting the numerical data the reaction forces are calculated as:

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

B.3 The Axial Force Diagram

The axial force diagram is drawn in Figure 2.2.c.

Figure 2.2.c

The axial force on the interval ![]() is a constant tension

force

is a constant tension

force![]() ,

while on the interval

,

while on the interval ![]() is a constant

compression force

is a constant

compression force![]() .

It can be concluded that both segments of the rod are uniform-axial deformed members.

.

It can be concluded that both segments of the rod are uniform-axial deformed members.

B.3 Stress and Strain Calculation

The stress and strain in the interval![]() , where the rod is made of solid steel are obtained as:

, where the rod is made of solid steel are obtained as:

![]()

![]()

![]() tension

stress

tension

stress

![]()

![]() elongation strain

elongation strain

In a similar manner is calculated the stress and strain

pertinent to the interval ![]() representing the

aluminum made rod.

representing the

aluminum made rod.

![]()

![]()

![]() compression

stress

compression

stress

![]()

![]() elongation

strain

elongation

strain

B.4 Calculation of the axial displacement

The displacement ![]() of the point

of the point![]() , the right end of the steel segment, is calculated:

, the right end of the steel segment, is calculated:

![]()

![]()

![]()

where the displacement at the origin of the interval ![]() and

and![]() ,

because the point is constraint against the horizontal movement.

,

because the point is constraint against the horizontal movement.

B.5 Verification of the Rod

The verification of the rod segments is conducted as:

for the steel segment

![]()

![]() ok

ok

where ![]() is the brass allowable

stress,

is the brass allowable

stress, ![]() is the brass yield

stress which can be found in Appendix 1.2, and is

is the brass yield

stress which can be found in Appendix 1.2, and is ![]() the safety factor .

For this calculation

the safety factor .

For this calculation ![]() and

and![]() .

.

for the aluminum segment

![]()

![]() ok

ok

where ![]() is the brass allowable

stress,

is the brass allowable

stress, ![]() is the aluminum yield

stress which can be found in Appendix 1.2, and

is the aluminum yield

stress which can be found in Appendix 1.2, and ![]() is the safety factor . For this calculation

is the safety factor . For this calculation ![]() and

and ![]() .

.

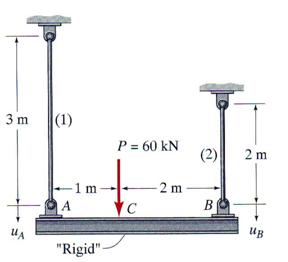

Problem 2.3

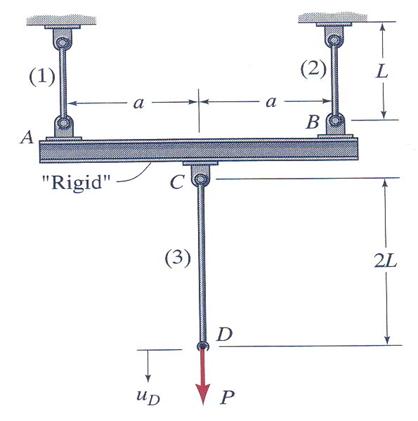

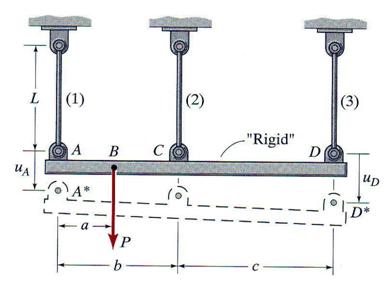

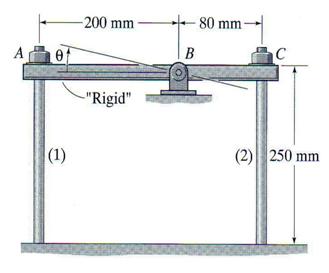

A rigid beam AB, shown in Figure 2.3.a, is supported by two vertical

rods made of steel with a modulus of elasticity E=200 GPa. The support rod

located at the end A has a diameter d1=25 mm. The weight of the beam

AB is negligible and is loaded at point C with a concentrated force P = 60 kN.

Calculated: (a) the diameter, d2, of the hanger located at the end

B, considering that the relation between the vertical displacement at the ends of

the beam ![]() , (b) under same condition the vertical displacement in node

C, (c) if the hanger located at end B of the rigid beam has a diameter d2=20

mm, what should be the position of the concentrated load P for relation

, (b) under same condition the vertical displacement in node

C, (c) if the hanger located at end B of the rigid beam has a diameter d2=20

mm, what should be the position of the concentrated load P for relation ![]() to be true, and (d)

the axial stresses in the hangers considering the conditions stipulated in the

previous question.

to be true, and (d)

the axial stresses in the hangers considering the conditions stipulated in the

previous question.

A. General Observations

A.1 The steel rod (1) has a length ![]() and diameter

and diameter![]() ,

while for the steel rod (2) only the length is known

,

while for the steel rod (2) only the length is known![]() .

Both rods are made of steel with a modulus of elasticity of steel

.

Both rods are made of steel with a modulus of elasticity of steel![]() .

.

Figure 2.3.a

A.2 The vertical concentrated force ![]() is located at point

is located at point ![]() at a distance of

at a distance of ![]() from the left end. The total distance

in-between the rigid beam supports is

from the left end. The total distance

in-between the rigid beam supports is![]() ,

while the distance from the application point

,

while the distance from the application point ![]() to point

to point ![]() is

is![]() .

.

B. Calculations

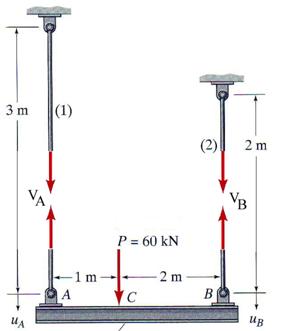

B.1 Free-Body Diagram

The rigid beam ![]() is supported at ends

is supported at ends ![]() and

and ![]() by two steel rods which are playing the supporting role for

the beam. Sectioning the rods and replacing them by two corresponding axial

forces

by two steel rods which are playing the supporting role for

the beam. Sectioning the rods and replacing them by two corresponding axial

forces![]() and

and![]() , the free-body diagram of the system is obtained as shown in

Figure 2.3.b.

, the free-body diagram of the system is obtained as shown in

Figure 2.3.b.

B.2 Reactions Calculation

Two moment equations are written:

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Figure 2.3.b

The two equilibrium equations are containing two unknowns,

the forces ![]() and

and![]() , and consequently, the system is statically determinate.

, and consequently, the system is statically determinate.

The verification of the reaction forces is done using the equilibrium equation of the projection of the forces on the vertical direction:

![]()

![]()

![]()

B.3 Calculation required by question (a)

The axial forces in the rods are tension type forces:

![]()

![]()

![]()

![]()

![]()

![]()

Because the axial forces in the rods and they have constant areas, both rods are uniform-axial deformed members. The flexibility coefficients are obtained as:

The geometrical condition required is:

Because the rod diameter is always a positive value, from the two above solutions only the positive value is a valid solution. Consequently, the diameter of the rod (2) is calculated as:

![]()

B.4 Calculations required by question (b)

The vertical displacement ![]() is composed from two components: one elastic and equal with

the vertical displacement

is composed from two components: one elastic and equal with

the vertical displacement ![]() and other rigid induced by the rigid rotation of the beam in

the vertical plane. The elastic vertical displacement

and other rigid induced by the rigid rotation of the beam in

the vertical plane. The elastic vertical displacement ![]() is calculated:

is calculated:

![]()

![]()

![]()

where

![]()

![]() is the flexibility coefficient of the

rod (1).

is the flexibility coefficient of the

rod (1).

The vertical displacement ![]() is obtained:

is obtained:

![]()

![]()

B.5 Calculations required by question (c)

The geometrical condition imposed is written as:

The flexibility coefficient of the rod (2) is calculated

considering that the rod diameter is![]() :

:

![]()

![]()

![]()

![]()

The position of the concentrated force measured from point ![]() is obtained by substituting the previously

calculated flexibility coefficients:

is obtained by substituting the previously

calculated flexibility coefficients:

![]()

![]()

B.6 Calculations required by the question (d)

The axial forces in the hangers are:

![]()

![]()

![]() for

rod (1)

for

rod (1)

![]()

![]()

![]() for rod (2)

for rod (2)

The axial stresses are obtained:

![]()

![]() tension stress in rod (1)

tension stress in rod (1)

![]()

![]() tension stress in rod (2)

tension stress in rod (2)

B.7 Verification of the rods

Considering that the steel yielding stress and the

safety coefficient employed are ![]() and

and![]() , respectively, the allowable steel stress is calculated as:

, respectively, the allowable steel stress is calculated as:

![]()

![]()

Consequently,

![]() the

rod (1) is ok

the

rod (1) is ok

![]() the

rod (2) is ok

the

rod (2) is ok

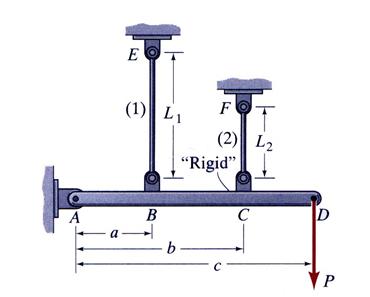

Problem 2.4

The system shown in Figure 2.a is composed of a rigid beam

AD, pinned into the wall at point A, and two unequal linear elastic rods, BE

and CF, made of steel with a modulus of elasticity ![]()

![]() . The steel rods lengths and areas are

. The steel rods lengths and areas are ![]()

![]() and

and![]()

![]() , and,

, and, ![]()

![]() and

and![]()

![]() , respectively. The system is loaded with by vertical force

, respectively. The system is loaded with by vertical force![]() acting at point D. The steel rods and force

acting at point D. The steel rods and force![]() locations are determined by the following distances measured

from point A:

locations are determined by the following distances measured

from point A: ![]()

![]() ,

,![]()

![]() and

and![]()

![]() , respectively. What

is the allowable force

, respectively. What

is the allowable force ![]() supported by the

system if the allowable normal stress for steel is

supported by the

system if the allowable normal stress for steel is![]()

![]() .

.

Figure 2.a

A. General Observations

The system illustrated in Figure 2.a is geometrical defined by the data contained in the text.

B. Calculations

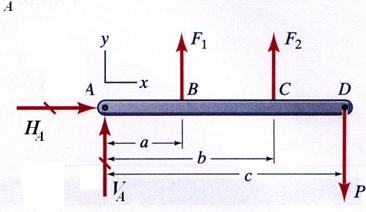

B.1 Free-Body Diagram

The rigid beam ![]() is supported at the ends

is supported at the ends![]() and

and ![]() by two steel rods, which are playing the supporting role for

the beam, together with the pinned support located at point

by two steel rods, which are playing the supporting role for

the beam, together with the pinned support located at point![]() . Sectioning the rods and replacing them by two corresponding

axial forces

. Sectioning the rods and replacing them by two corresponding

axial forces![]() and

and![]() , and substituting the constraints introduced by the pinned support

by its corresponding reaction forces,

, and substituting the constraints introduced by the pinned support

by its corresponding reaction forces, ![]() and

and ![]() , the free-body diagram of the system is obtained and illustrated

in Figure 2.b.

, the free-body diagram of the system is obtained and illustrated

in Figure 2.b.

Figure 2.b

B.2 Reactions Calculation

The following equilibrium equations are written:

![]()

![]() no

axial force

no

axial force

![]()

![]()

![]()

![]()

The last two equilibrium equations contain three unknown

reaction forces![]() ,

, ![]() and

and![]() . The system is

statically indeterminate. In order to find these unknown quantities one additional equation is necessary. This equation is obtained from the

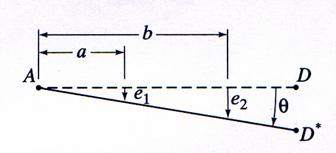

deformation compatibility condition schematically described in Figure 2.c.

. The system is

statically indeterminate. In order to find these unknown quantities one additional equation is necessary. This equation is obtained from the

deformation compatibility condition schematically described in Figure 2.c.

Because the beam AD is rigid, purely geometric relations between

the rod elongations,![]() and

and![]() , and the rotation angle

, and the rotation angle![]() are written as:

are written as:

![]()

![]()

Figure 2.c

Using the elongation expressions the forces in the rods are calculated as:

![]()

![]()

![]()

![]()

where the stiffness coefficients, ![]() and

and![]() , are calculated from the geometrical and material properties

characteristics of the rods as:

, are calculated from the geometrical and material properties

characteristics of the rods as:

![]()

![]()

![]()

![]()

Substituting the expressions of the rod forces into the last

two equilibrium equations the three original unknowns,![]() ,

,![]() and

and ![]() , are replaced with two unknowns,

, are replaced with two unknowns, ![]() and

and![]() . The equilibrium equations are then written as:

. The equilibrium equations are then written as:

![]()

![]()

![]()

Solving the algebraic system, the two unknowns are found as:

The axial forces in the rods are calculated:

To find the force ![]() producing an allowable stress

producing an allowable stress ![]() in the rods the following equations are written:

in the rods the following equations are written:

![]() for rod (1)

for rod (1)

![]() for rod (2)

for rod (2)

The allowable force![]() for the entire system is:

for the entire system is:

![]()

![]()

![]()

The vertical displacements at point ![]() and

and ![]() are then calculated:

are then calculated:

![]()

![]()

Problem 2.5

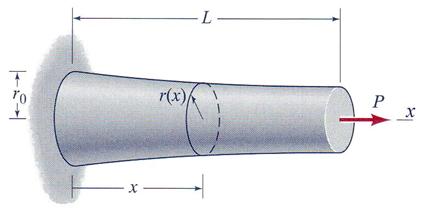

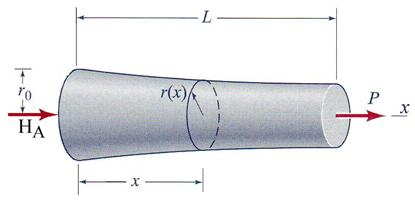

An axial load P is applied to a tapered circular rod of length L as shown in Figure 2.5.a. The variation of the rod radius along its length is expressed as:

where ![]() is the radius at the

left end cross-section.

is the radius at the

left end cross-section.

Symbolically express: (a) the axial stress![]() , (b) the elongation strain

, (b) the elongation strain![]() and (c) the total elongation

and (c) the total elongation![]() . Apply the above obtain expressions for the case when where

P = 9 kN, L = 2.50 m, r0 = 0.50 m and the rod is made of an aluminum

alloy for which E = 69 GPa.

. Apply the above obtain expressions for the case when where

P = 9 kN, L = 2.50 m, r0 = 0.50 m and the rod is made of an aluminum

alloy for which E = 69 GPa.

Figure 2.5.a

A. General Observations

The tapered aluminum rod is subjected to a non-uniform axial deformation, because the area is not constant along the length of the beam.

The variation of the area along its axis is expressed as:

![]()

where ![]() is the area

representing the cross-section at the left end of the rod (x=0).

is the area

representing the cross-section at the left end of the rod (x=0).

B. Calculations

B.1 Free-Body Diagram

The free-body diagram is illustrated in Figure 2.5.b.

Figure 2.5.b

B.2 Reaction Calculation

The constraint located at the left end of the beam is

replaced by a horizontal concentrated reaction force![]() . The reaction force

. The reaction force ![]() is calculated using the equilibrium equation involving the

horizontal projection of all forces.

is calculated using the equilibrium equation involving the

horizontal projection of all forces.

![]()

![]()

![]()

The system is statically determinate.

B.3 Expression of the Axial Stress

The axial force in the rod is constant and represents a tension force:

![]()

The general expression of the axial stress in the rod is obtained as:

where ![]() is the axial stress in the cross-section located at the left

end of the rod.

is the axial stress in the cross-section located at the left

end of the rod.

B.4 Expression of the Axial Strain

where ![]() is the axial stress in the cross-section located at the left

end of the rod.

is the axial stress in the cross-section located at the left

end of the rod.

B.5 Expression of the Rod Total Elongation

The total elongation is obtained as:

B.6 Numerical Application

The following data is substituted in the above obtained expressions:

![]()

![]()

![]()

![]()

The reaction force is:

![]()

![]()

The area at the left end cross-section:

![]()

![]()

The axial stress and elongation strain at the left end cross-section are:

![]()

![]()

The variation of the axial stress and elongation strain are calculated in a number of twenty-one sections:

![]()

![]()

The maximum values are calculated in the right end cross-section (x = L):

![]()

![]()

![]()

![]()

The total elongation of the rod is:

![]()

![]()

The variation of the axial stress is illustrated in Figure 2.5.c.

Figure 2.5.c

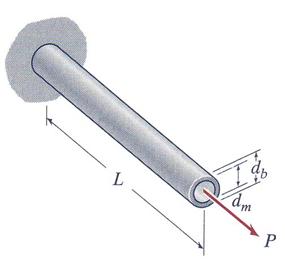

Problem 2.6

A magnesium-alloy rod (Emag = 45 GPa) of diameter dm = 30 mm is encased by a brass tube (Ebra = 100 GPa) with outer diameter db. Both bars have an equal length L = 500 mm. An axial load P = 40 kN is applied to the resulting bimetallic rod. Assuming that that the magnesium rod and the brass tube are securely bonded to each other calculate: (a) the outer diameter db of the tube, if three fourths of the load P is carried by the magnesium rod and one fourth by the brass tube and (b) the total elongation of the bimetallic rod. The bimetallic rod is illustrated in Figure 2.6.

A. General Observations

A.1 It is assumed, due to the bondage between the materials, that the deformation at the right end cross-section of the bimetallic rod is equal for both materials.

A.2 The reaction force located at the left end of the rod is

not necessary to be calculated, because the distribution of the external force ![]() in-between the magnesium and brass cross-section is established.

in-between the magnesium and brass cross-section is established.

![]()

![]() for magnesium

for magnesium

![]()

![]() for brass

for brass

Note: It can be remarked that the bimetallic rod it is statically determined system, but because the modulus of elasticity is not constant for the entire length of the rod, the rod is subjected to a nonuniform-axial deformation.

Figure 2.6

B. Calculations

B.1 Calculation of the brass exterior diameter ![]()

The equality of the deformation at the right end of the bimetallic rod is:

![]()

Using the flexibility coefficients ![]() and

and![]() , corresponding to magnesium and brass rods the displacements

equality is written as:

, corresponding to magnesium and brass rods the displacements

equality is written as:

![]()

where ![]() and

and ![]() .

.

Substituting the forces and the flexibility coefficients into the above equation, the expression of the brass area is obtained:

The area of the magnesium rod is calculated as:

![]()

![]()

and consequently, the area of the brass rod is obtained:

![]()

![]()

The exterior diameter of the brass tube is calculated from the following equation:

![]() because only the positive value makes sense.

because only the positive value makes sense.

B.2 Calculation of total elongation

The total elongation is equal to the displacement of the either material calculated at the right end of the rod. The calculation is conducted using the data pertinent for magnesium and is also verified using the brass data.

![]()

![]()

![]()

![]()

![]()

![]()

The verification using brass:

![]()

![]()

![]()

![]()

Note: It can be remarked that the deformation of both materials is 1.572*10-4 m and, this way, the geometrical condition imposed is also verified numerically.

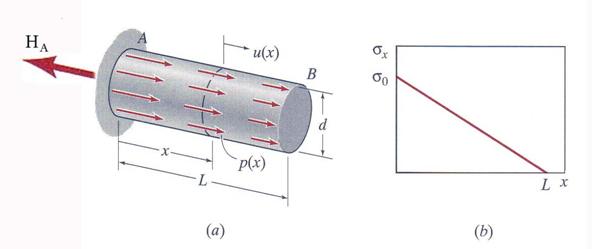

Problem 2.7

A uniform circular cylinder of diameter d and length L is

made of a material with modulus of elasticity E. It is fixed to a rigid wall at

end A and subjected to a distributed external axial loading of magnitude p(x)

per unit length, as shown in Figure 2.7.a. The axial stress,![]() , varies linearly with x as shown in Figure 2.7.b. Determine:

(a) the expression for the distributed loading, p(x) and (b) the expression for

the axial displacement, u(x), of the cross section.

, varies linearly with x as shown in Figure 2.7.b. Determine:

(a) the expression for the distributed loading, p(x) and (b) the expression for

the axial displacement, u(x), of the cross section.

Figure 2.7

A. General Observations

A.1 The member is subjected to a nonuniform-axial deformation and it is statically determinate system.

A.2 The axial stress has the following expression (see Figure 2.7):

![]()

B. Calculations

The horizontal reaction force ![]() is calculated

as:

is calculated

as:

![]()

The axial force pertinent to a particular cross-section is obtained from the equilibrium as:

The axial stress is expressed:

Comparing the above expression with the expression given by the problem the following equation is written:

and after the algebraic

manipulation the integral becomes:

and after the algebraic

manipulation the integral becomes:

Consequently,

It can be concluded that the linear variation of the axial stress is induced by a constant axially applied load.

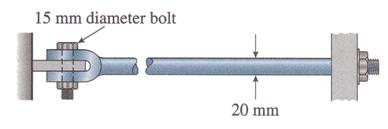

Problem 2.8

Two rods are stress-free when welded together at point ![]() and welded to two

rigid walls at points

and welded to two

rigid walls at points ![]() and

and![]() . The geometrical and material characteristics of the two

rods are illustrated in Figure 2.8.a. Subsequently, rod (1) and rod (2) are

heated by an amount

. The geometrical and material characteristics of the two

rods are illustrated in Figure 2.8.a. Subsequently, rod (1) and rod (2) are

heated by an amount![]() and

and![]() , respectively from their initial installation temperature.

Determine an expression for the axial forces induced in each rod by the change

in temperatures.

, respectively from their initial installation temperature.

Determine an expression for the axial forces induced in each rod by the change

in temperatures.

Figure 2.8.a

A. General Observations

A.1 The rods have the same modulus of elasticity![]() , but different expansion coefficients

, but different expansion coefficients ![]() and

and![]() .

.

A.2 It can be remarked the absence of any external load and the existence of a change in temperature

B. Calculations

B.1 Free-Body Diagram

The free-body diagram is illustrated in Figure 2.8.b.

Figure 2.8.b

B.2 Reaction Calculation

The constraints located at the left and right end points,![]() and

and![]() , of the member are replaced by two horizontal reaction

forces,

, of the member are replaced by two horizontal reaction

forces, ![]() and

and![]() , respectively. The following equilibrium equation is

written:

, respectively. The following equilibrium equation is

written:

![]()

![]()

![]()

The system is statically

indeterminate and in order to calculate the reaction forces an additional

equation is necessary. This equation is the fact that the total elongation ![]() is zero:

is zero:

![]()

The expression of the displacements ![]() and

and ![]() are:

are:

![]()

![]()

where

![]() and

and ![]() are the flexibility coefficients

are the flexibility coefficients

The axial forces in the rods are:

![]() and

and ![]()

The elongation is calculated as:

![]()

From the condition imposing that the total elongation to be

zero, the reaction force ![]() is obtained:

is obtained:

![]()

Consequently, the reaction force ![]() is:

is:

![]() and the forces ion the

rods are:

and the forces ion the

rods are:

![]()

3 Proposed Problems

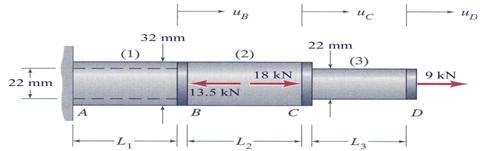

Problem 3.2

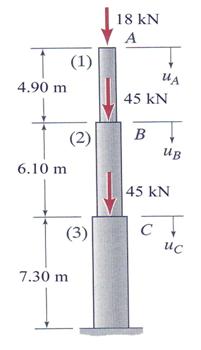

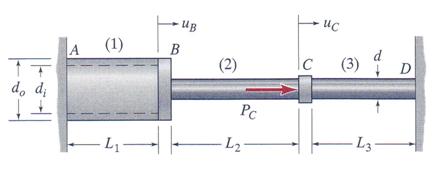

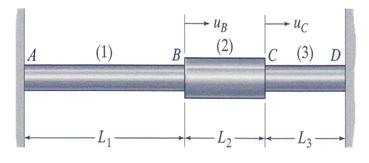

The three-part axially loaded member, shown in Figure 3.2,

consists of a tubular segment (1) with outer diameter ![]() and inner diameter

and inner diameter![]() , a solid circular rod segment (2) with diameter

, a solid circular rod segment (2) with diameter ![]() and a third solid circular rod segment (3) with diameter

and a third solid circular rod segment (3) with diameter![]() .

.

Figure 3.2

All three applied loads shown are acting along the

centroidal axis of the members. Considering that the rigid couplers have a

negligible length determine: (a) the axial stresses in each one of the three

respective segments, (b) the displacements in points B, C and D if all segments

have equal lengths L1 = L2 = L3 = 0.50 m and

the modulus of elasticity of the material is ![]() .

.

Problem 3.3

The diameter of the central one-third of a 50 mm diameter steel rod is reduced to 20 mm, forming a three-segment rod, as shown in Figure 3.3. For the loading shown, determine the displacements of the rod points B, C and D, respectively. The rod is made of a material which has the modulus of elasticity E = 200 GPa.

Figure 3.3

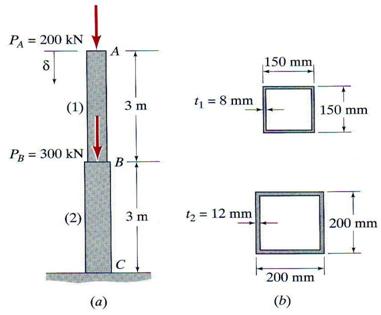

Problem 3.4

A column in a two-story building is fabricated from square structural steel tubing having a modulus of elasticity E = 210 GPa. The cross-sectional dimensions of the two segments are shown in Figure 3. Two axial loads acting along the centroidal axis of the column are applied to the column at levels A and B. Calculate: (a) the axial stress both segments of the column and (b) the total shortening of the column length

Figure 3.4

Problem 3.5

A three-segment stepped aluminum-alloy column is subjected to the vertical axial loads shown in Figure 3.5 The cross-sectional areas of the segments are A1 =3870 mm2, A2 =5810 mm2 and A3 =9035 mm2, respectively. The material modulus of elasticity is E = 69 GPa. Calculate: (a) the axial stresses in all three segments and (b) the vertical displacement of the column at nodes A, B and C under the given loading system.

Figure 3.5

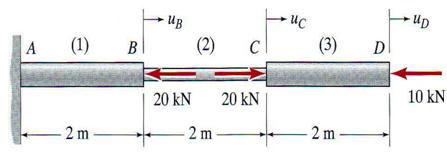

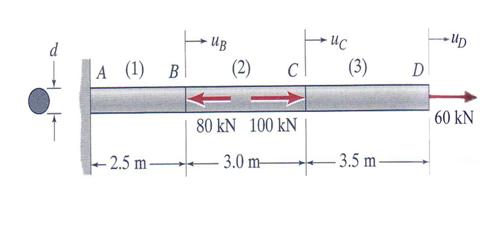

Problem 3.6

A uniform rod is subjected to three axial loads acting as shown in Figure 3.6 and is made of a material with a modulus of elasticity E = 70 GPa. What is the minimum allowable diameter of the cylindrical rod if the displacement at the right end D and the maximum axial stress in the rod can not excide 5 mm and 80 MPa, respectively?

Figure 3.6

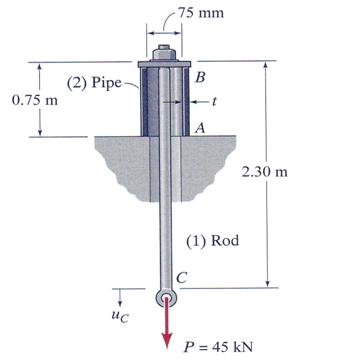

Problem 3.7

A 1.2 in diameter aluminum-alloy hangar, illustrated in

Figure 3.7, is supported by a steel pipe with an inside diameter of![]() =75 mm. The moduli of elasticity for the steel pipe and

hanger are Esteel =

=75 mm. The moduli of elasticity for the steel pipe and

hanger are Esteel =![]() MPa and Ealuminum =

MPa and Ealuminum =![]() MPa, respectively. Determine the thickness of the steel pipe

if the maximum axial displacement at the node C is 2.5 mm.

MPa, respectively. Determine the thickness of the steel pipe

if the maximum axial displacement at the node C is 2.5 mm.

Figure 3.7

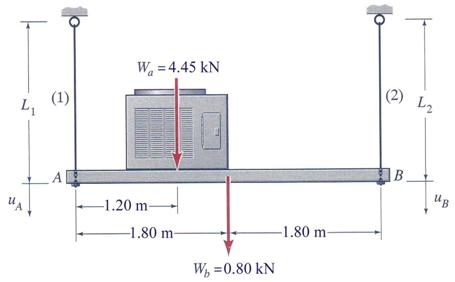

Problem 3.8

A 3.60 m rigid beam AB that weighs 0.80 kN supports an air conditioner that weighs Wair=45 kN. The beam is supported by hanger rods (1) and (2) located at its ends as shown in Figure 3.8.

Figure 3.8

Conduct the following calculations: (a) if the diameter of

rod (1) is 95 mm what is the stress in the rod? (b) if the stress in rod (2) is

to be the same as the stress in rod (1), what should the diameter of rod (2)?

(c) what are the downward displacements at the ends of the rigid beam if the

rods length are L1 = L2 = 1.80 m and they are made of

steel with a modulus of elasticity E =210![]() 103 MPa?

103 MPa?

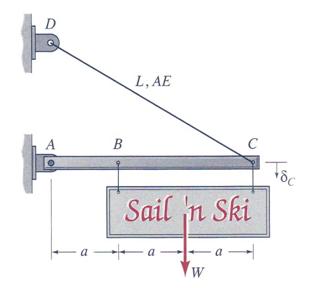

Problem 3.9

A hanger rod CD is attached to a rigid beam AB. The beam is supported at its ends by two hanger rods. Assuming that all tree hangers are identical and are made from the same material, calculate: (a) the axial stress in all tree hangers, (b) the vertical displacement of the points A, B, C and D.

Figure 3.9

Problem 3.10

A commercial sign of weight W is supported by a structural system comprised from a rigid beam AB and a wire CD, as shown in Figure 3.10. The rigid beam has a negligible weight, while the wire has length L, cross-sectional area A, and modulus of elasticity E. Assuming that the attachment pin D is directly located above pin A, and when there is no load acting on the beam, the beam is in a perfect horizontal position calculate the following: (a) the axial stress in the wire CD when the sign is attached at points B and C of the beam, (b) the vertical displacement in point C of the beam.

Figure 3.10

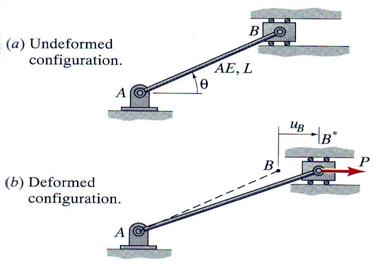

Problem 3.11

The inclined rod AB, shown in Figure 3.12, is pinned to a

fixed support at A and is pinned at the end B to a block that is forced to move

only horizontally when the load P is applied. Determine: (a) an expression for

the axial stress in the inclined rod as a function of P, L, E, A, and the angle![]() , (b) an expression for the horizontal displacement at the

end B.

, (b) an expression for the horizontal displacement at the

end B.

Figure 3.11

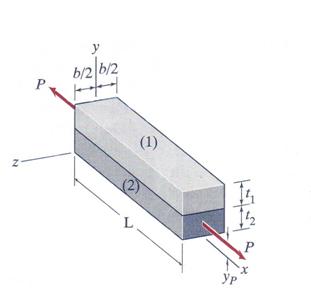

Problem 3.12 A bimetallic bar is made by bonding together two homogeneous rectangular bars, each having a width b, length L and moduli of elasticity of the bars are E1 and E2, respectively. An axial force P is applied to the ends of the bimetallic bar at location (y= yp, z = 0) such that the bar undergoes an axial deformation only. Assuming the following data: L = 1.5 m, b = 50 mm, t1 = 25 mm, t2 = 15 mm, E1 = 70 GPa, E2 = 210 GPa and P = 48 kN. Calculate: (a) the normal stress in each material, (b) the value of yp, (c) the elongation of the bar.

Figure 3.12

Problem 3.13

A bimetallic bar, shown in Figure 3.13, undergoes an axial deformation. The bar has the following geometrical and material characteristics: L = 2.55 m, b = 50 mm and h1 = h2 = 1.50 mm and E1=210 GPa. Calculate: (a) the modulus of elasticity E2 if the load P is applied at 10 mm, and (b) the total elongation of the bar for a load of P = 9 kN.

Figure 3.13

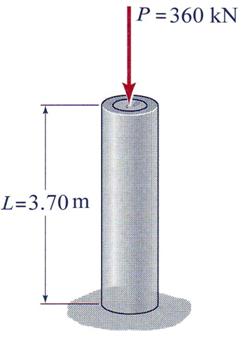

Problem 3.14

A steel pipe is filled with concrete, and the resulting column is subjected to a compressive load P = 360 kN. The pipe has an outer diameter of 325 mm and an inside diameter of 305 mm. The elastic moduli of the steel and concrete are: Estel = 210 GPa and Econc = 25 GPa. Determine: (a) the stress in the steel and the stress in the concrete due to this loading, (b) the shortening of the column if its initial length is L = 3.70 m, (Ignore- radial expansion of the concrete and steel due to Poisson's ratio effect.)

Figure 3.14

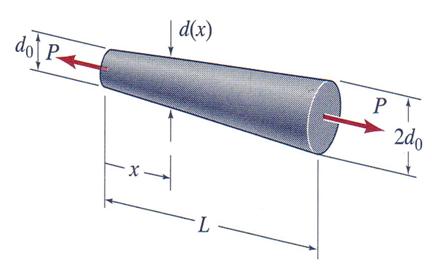

Problem 3.15

A homogenous rod of length L and elasticity modulus E is a

conical frustum with diameter d(x) that varies linearly from d0 at

one end to 2*d0 at the other end, with d0 << L. An axial

load P is applied to the rod, as shown in Figure 3.15. Determine analytical

expressions for: (a) the stress distribution,![]() , on an arbitrary cross section and (b) the elongation of the

rod,

, on an arbitrary cross section and (b) the elongation of the

rod, ![]() .

.

Figure 3.15

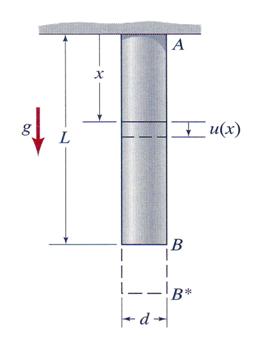

Problem 3.16 A uniform circular cylinder of diameter

d and length L is made of a material with modulus of elasticity E and specific weight![]() . It hangs from a rigid ceiling as shown in Figure 3.16.

Determine: (a) the expression of the axial stress

. It hangs from a rigid ceiling as shown in Figure 3.16.

Determine: (a) the expression of the axial stress![]() , (b) the expression of the strain

, (b) the expression of the strain![]() , (c) the expression of the displacement

, (c) the expression of the displacement![]() and (d) the compression force necessary to be applied in

order to return the bar at its initial length.

and (d) the compression force necessary to be applied in

order to return the bar at its initial length.

Figure 3.16

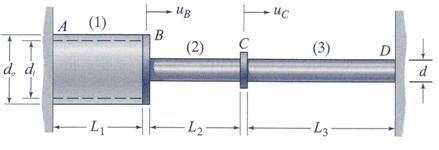

Problem 3.17

A steel pipe with outer diameter do = 50 mm, and inner diameter di = 38 mm and a solid aluminum-alloy rod of diameter d = 19 mm form a three-segment system that undergoes axial deformation due to a single external load PC = 55 Kn acting on a collar at point C, as shown in Figure 3.17. Considering the following data: L1 = L2 = 0.75m, L3 = 1.20 m, E1 = 210 GPa and E2 = E3 = 69 GPa, calculate: (a) the axial stresses induced in all three segments and (b) determine the axial displacement at points B and C.

Figure 3.17

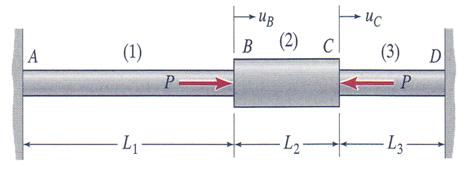

Problem 3.18

A three-segment rod is attached to rigid supports at ends A and D and is subjected to equal and opposite external loads P at nodes B and C, as shown in Figure 3.18. The rod is homogeneous and linearly elastic, with modulus of elasticity E. Assuming A1 = A3 = A and A2 = 2A, L1 = 2L and L2 = L3 = L, calculate: (a) the axial stresses in all tree segments and (b) the horizontal displacements at nodes B and C, respectively.

Figure 3.18

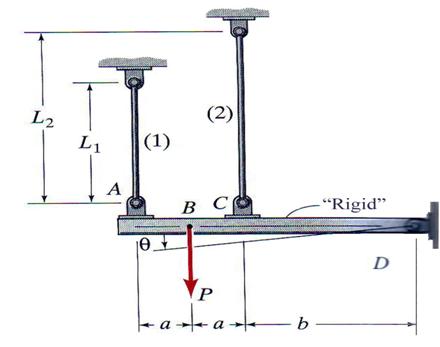

Problem 3.19

A rigid beam AD, supported by a pin at its end point D and attached

by the two vertical steel rods at points A and C, is loaded by a vertical load

P at point B. Neglecting the weight of the beam and assuming that the support

rods are stress-free when P = 0, calculate: (a) the forces F1 and F2

in the support rods after load P is applied, (b) the deformation of the

supporting and (c) the expressions previously obtained if A1 = A2

= 500![]() , L1 = 1m, L2 = 2m , E1 = E2

= 210 GPa, P = 50 kN, a = 0.50 m and b = 1.5 m.

, L1 = 1m, L2 = 2m , E1 = E2

= 210 GPa, P = 50 kN, a = 0.50 m and b = 1.5 m.

Figure 3.19

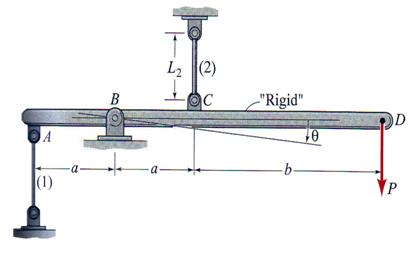

Problem 3.20

A rigid beam AD, shown in Figure 3.20, is supported by a smooth pin at B and by two vertical rods attached to the beam at points and C. Neglecting the weight of the beam and assuming that the rods are stress-free when P = 0. Considering that A1 = 650 mm2, A2 = 325 mm2, L1 = L2 = 1.25 m, a = 0.60 m, b = 1.25m, E1 = E2 = 69 GPa and P = 22.70 kN, determine: (a) the axial forces in the support rods, (b) determine the axial stress in each support and (c) calculate the elongation of the support rods.

Figure 3.20

Problem 3.21

A rigid beam AD, shown in Figure 3.21, is supported by three identical vertical rods that are attached to the beam at points A, C, and D and loaded in node B with a vertical concentrated load P. Assuming that A = 650 mm2, L = 1.50 m, a = 0.50 m, b = 1.00 m, c = 1.50 m, E = 210 GPa and P = 45.5 kN, calculate: (a) the axial forces in the support rods and (b) the vertical displacements at nodes A, B, C and D.

Figure 3.21

Problem 3.22

The rod composed from two segments as shown in Figure 3.22,

is attached to rigid walls at A and C. Determine expressions for the stresses

pertinent to both segments resulting from a uniform temperature increase ![]() of the entire rod. Numerical application: A1 =

1000 mm2, A2 = 1500 mm2, L1 = 2 m,

L2 = 1.5 m, E1 = 210 Gpa, E2 = 120 GPa, a1 = 12*10-6 and a2 = 8.0*10-6 and

of the entire rod. Numerical application: A1 =

1000 mm2, A2 = 1500 mm2, L1 = 2 m,

L2 = 1.5 m, E1 = 210 Gpa, E2 = 120 GPa, a1 = 12*10-6 and a2 = 8.0*10-6 and ![]() = 30

= 30![]() .

.

Figure 3.22

Problem 3.23

A three-segment rod shown in Figure 3.23 is rigidly attached to walls at points A and D. Subsequently, the middle segment is heated by an amount, while the segments (1) and (3) are kept at their original temperature. Using the notation shown in Figure 3.23 and considering the system free at stress at the installation, calculate the stresses in the segments and the axial displacements at points B and C.

Figure 3.23

Problem 3.24

A steel pipe with outer diameter do, and inner

diameter di and a solid aluminum-alloy rod of diameter d form a

three-segment system as shown in Figure 3.2 The system is considered stress

free when is welded to the rigid supports at points A and D. The installation

temperature ![]() is recorded.

Subsequently, the aluminum rod is cooled by 100F (

is recorded.

Subsequently, the aluminum rod is cooled by 100F (![]() ), while the steel pipe is held at the initial temperature

), while the steel pipe is held at the initial temperature![]() . Assuming do = 50 mm, di = 38 mm, d = 19 mm, L1 = 1.25 m, L2

= L3= 0.75 m, E1 = E3 = 210 GPa, E2

= 69 GPa, a1 = a3 =

6.5*10-6 and a2

. Assuming do = 50 mm, di = 38 mm, d = 19 mm, L1 = 1.25 m, L2

= L3= 0.75 m, E1 = E3 = 210 GPa, E2

= 69 GPa, a1 = a3 =

6.5*10-6 and a2

Figure 3.24

Problem 3.25

The mechanical system shown in Figure 3.25 is composed from two identical steel rods (A = 40 mm2, E = 200 GPa, a = 12.0*10-6) and a 'rigid' beam AC. The beam is supported by a smooth pin at B. Assuming the two rods stress-free after installation, determine: (a) the axial stresses induced in rods if their temperature is decreased by 50C and (b) the small angle q through which the beam AC would rotate due to this temperature change.

Figure 3.25

Problem 3.26

The steel rod of diameter 20 mm is held without any initial stresses between two rigid walls as illustrated in Figure 3.26. Determine the temperature drop DT at which the stress in the rod reaches 200 MPa. Use for the steel E=200 GPa and a = 12.0*10-6.

Figure 3.26

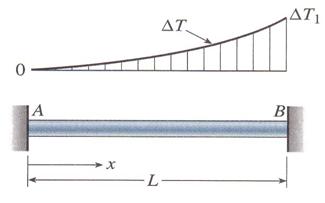

Problem 3.27

The bar AB, shown in Figure 3.27, is held between rigid supports and heated nonuniformly in such a manner that the temperature increase DT at distance x from end A is given by the expression DT (x) = DT1*(x/L)2, where DT1 is the increase in temperature at end B of the bar. Obtain a formula for the compressive stress in the bar. (Assume that bar has a length L and is made of a material with modulus of elasticity E and coefficient of thermal expansion a.)

Figure 3.27

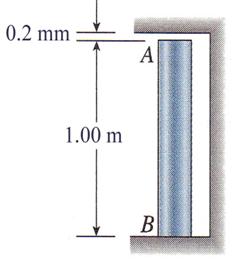

Problem 3.28

The copper bar AB of length 1.00 m is placed in position shown in figure 3.28 at room temperature. A gap of 0.2 mm exists between the end A of the bar and a rigid restraint. Calculate the axial compressive stress in the bar if the temperature is raised 90F. Use for copper the following material constants: E=110 GPa and a = 9.8*10-6.

Figure 3.28

Problem 3.29

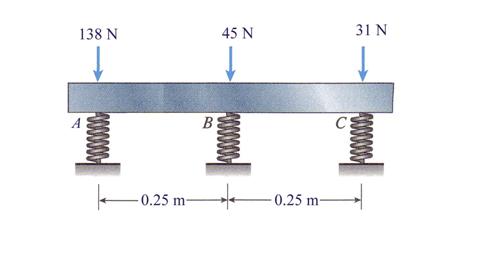

Three identical springs, 10 in. apart, are attached to a horizontal rigid bar at points A, B, and C, as illustrated in Figure 3.29. Three vertical loads of magnitudes 138 N, 45 N and 31 N act at points A, B, and C, respectively. Calculate the angle of rotation q (degrees) of the rigid bar if the spring stiffness k is 14 N/m.

Figure 3.34

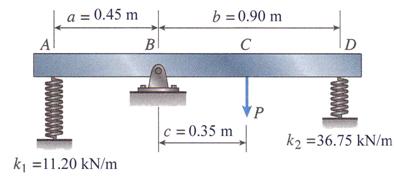

Problem 3.30

The rigid bar ABCD, shown in Figure 3.30, is pinned at point B and supported by springs at A and D. The springs at A and D have stiffnesses k1 = 11.20 kN/m and k2 = 36.75 kN/m, respectively. The dimensions a, b, and c are 0.45 m, 0.90 m, and 0.35 m, respectively. A load P acts at point C. Determine the maximum permissible load Pmax if the angle of rotation of the bar due to the action of the load P is limited to 2.

Figure 3.30

|

Politica de confidentialitate | Termeni si conditii de utilizare |

Vizualizari: 6832

Importanta: ![]()

Termeni si conditii de utilizare | Contact

© SCRIGROUP 2025 . All rights reserved